Inorganic heat-insulation nano material aqueous slurry, building glass heat-insulation coating and preparation method

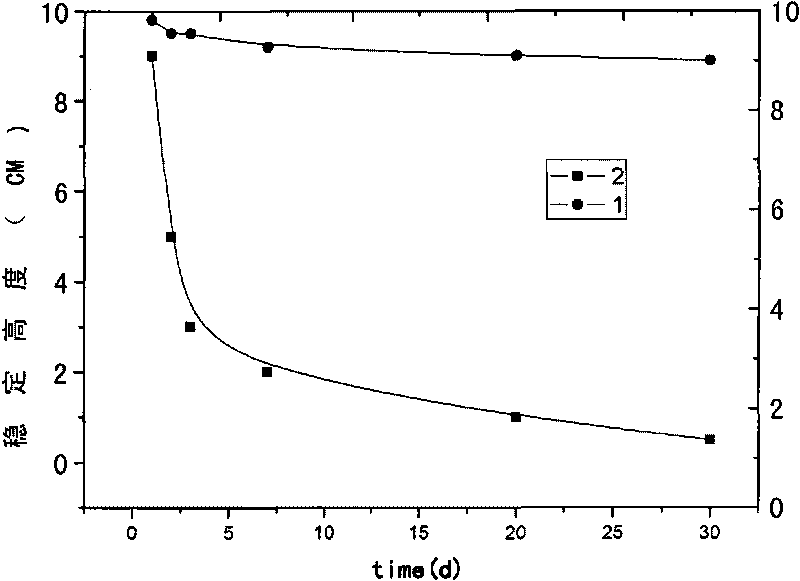

A technology of nanomaterials and water-based slurry, which is applied in the field of heat insulation materials, can solve the problems of poor dispersion, easy agglomeration of inorganic heat insulation nanomaterials, and poor stability, so as to improve heat insulation performance, compatibility and system Dispersion stability, effect of enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

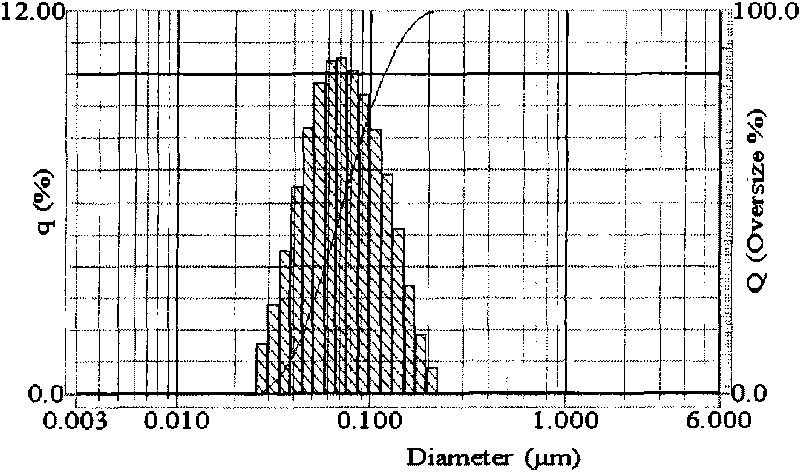

[0046] In this embodiment, the aqueous slurry of inorganic heat-insulating nanomaterials with controllable interface properties is based on a star-shaped siloxane polymer: 4-dendrimer: 2,4,6,8-tetramethyltripolysilicon Oxyalkylene[4]-(2-Hydroxyethyl Methacrylate) 2 : 2-hydroxyethyl methacrylate is used as a template, and the silicon-oxygen bond and hydrogen bond formed on the surface of the ITO nanomaterial obtain a stably dispersed aqueous slurry; the solid content of the aqueous slurry is 20%, and the thermal insulation nanomaterial ITO The particle size is all at 50-100nm, and its components and parts by weight are as follows:

[0047] Thermal insulation nanomaterials: ITO 15

[0048] Deionized water 75

[0049] 4-dendrimer: 2,4,6,8-tetramethyltripolysilane

[0050] Oxyalkylene[4]-(2-Hydroxyethyl Methacrylate) 2 : 10

[0051] 2-Hydroxyethyl methacrylate

[0052] Sample 1:

[0053] First weigh 15g of nano-indium tin oxide (ITO) and put it into 75g of water to adjust t...

Embodiment 2

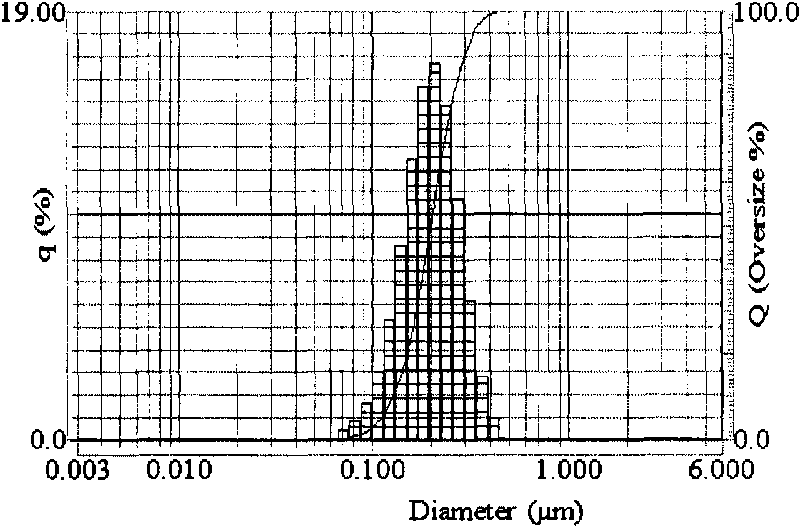

[0058] The aqueous slurry of inorganic heat-insulating nanomaterials with controllable interface properties is obtained by forming silicon-oxygen bonds and hydrogen bonds on the surface of ITO nanomaterials using linear siloxane polymer polydiethoxy (dimethyl) silane as a template. Stably dispersed water-based slurry; the solid content of the water-based slurry is 30%, and the particle size of the heat-insulating nano-material ITO is 50-100nm, and its components and parts by weight are as follows:

[0059] Thermal insulation nanomaterials: ITO 15;

[0060] Deionized water 75;

[0061] Linear polydiethoxy(dimethyl)silane 10;

[0062] The specific preparation steps are the same as the preparation method of sample 1 in Example 1.

Embodiment 3

[0064] The aqueous slurry of inorganic heat-insulating nanomaterials with controllable interface properties is based on comb-shaped siloxane polymer poly((1, vinylsilyl-2,4,8-trivinylundecane)-g-( Dimethylchlorosilane)) as a template, the silicon-oxygen bond and the hydrogen bond formed on the surface of the ITO nanomaterial obtain a stably dispersed water-based slurry; the solid content of the water-based slurry is 25%, and the particle diameter of the heat-insulating nanomaterial ITO The size is 50-100nm, and its components and parts by weight are as follows:

[0065] Thermal insulation nanomaterials: ITO 15;

[0066] Deionized water 75;

[0067] Comb poly((1, vinylsilyl-2,4,8-

[0068] 10;

[0069] Trivinylundecane)-g-(dimethylchlorosilane))

[0070] The specific preparation steps are the same as the preparation method of sample 1 in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com