Method for forming carbon nanotube film, film-forming apparatus, and carbon nanotube film

A technology of carbon nanotubes and film-forming methods, which is applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve problems such as high heat resistance, non-heat-resistant substrates, and inability to apply polymer materials to achieve optical properties homogeneous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0078] Hereinafter, embodiments of the present invention will be described in detail based on the drawings. In addition, the following examples are for making the invention of this application easier to understand, but are not limited to these examples. That is, modifications, implementation aspects, and other examples based on the technical idea of the invention of this application are also included in the invention of this application.

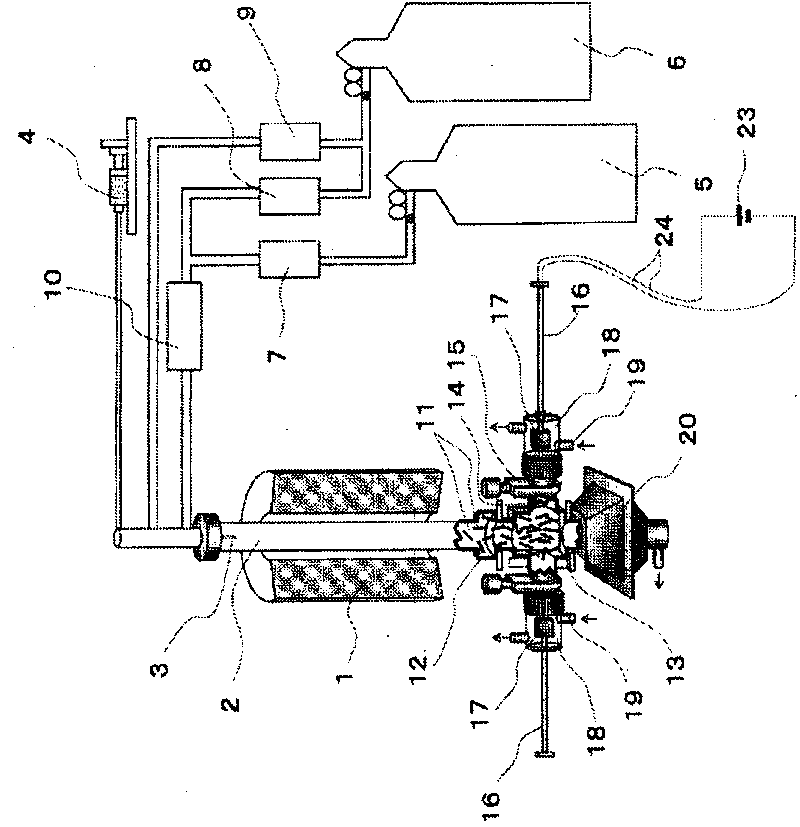

[0079] figure 1 It is a front view for explaining the entire single-walled carbon nanotube thin film manufacturing apparatus of the embodiment of the present invention, and the main part is shown in cross section.

[0080] In this manufacturing device, the part for synthesizing single-walled carbon nanotubes 11 includes an electric furnace 1, a mullite reaction tube 2, a spray nozzle 3, a microfeeder 4, a second carbon source 5, a carrier gas source 6, The second carbon source flow meter 7, the first carrier gas flow meter 8, the second carrie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com