Method for preparing silicon dioxide magnetic composite microballoon with core-shell structure

A technology of magnetic composite microspheres and silicon dioxide, which is applied in the fields of magnetism of inorganic materials, manufacture of inductors/transformers/magnets, electrical components, etc., can solve problems such as difficulty in particle size control, unfavorable biological applications, rough surface of microspheres, etc., to achieve Ease of cleaning, controllable shell thickness, and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

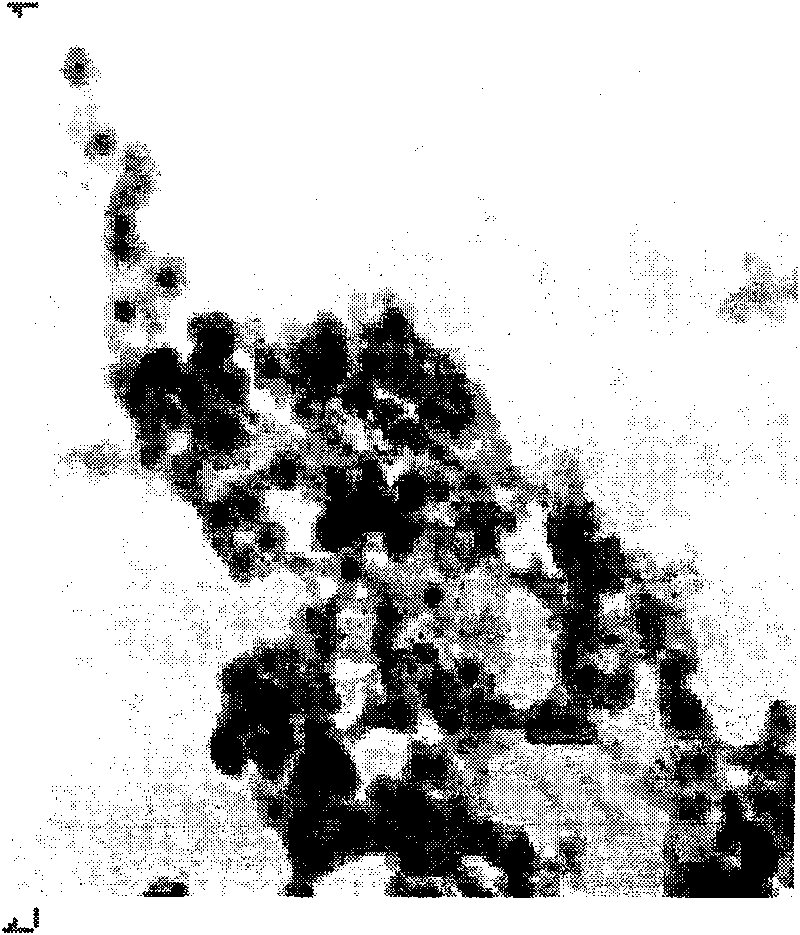

[0027] Example 1: Preparation of silica magnetic composite microspheres with a particle diameter of 50 nm and a core-shell structure.

[0028] 15 mg of iron oxide nanoparticles with a particle diameter of 8 nm monodispersed in water were added to the mixed solution of ethanol and water with a volume ratio of 1:1, and stirred for 0.3 h at a stirring speed of 300 rpm. Add 0.02ml tetraethyl orthosilicate to the above solution, stir for 2h at a stirring speed of 400rpm, then add 0.5mL concentrated ammonia water, and continue stirring for 24h. The silica magnetic composite microspheres with a core-shell structure are separated from the solution by an external magnetic field, the supernatant is discarded, the silica magnetic composite microspheres are washed with ultrapure water and absolute ethanol, and dispersed in water. The silica magnetic composite microspheres with a core-shell structure with a particle size of 50nm were obtained, and the electron microscope characterization o...

Embodiment 2

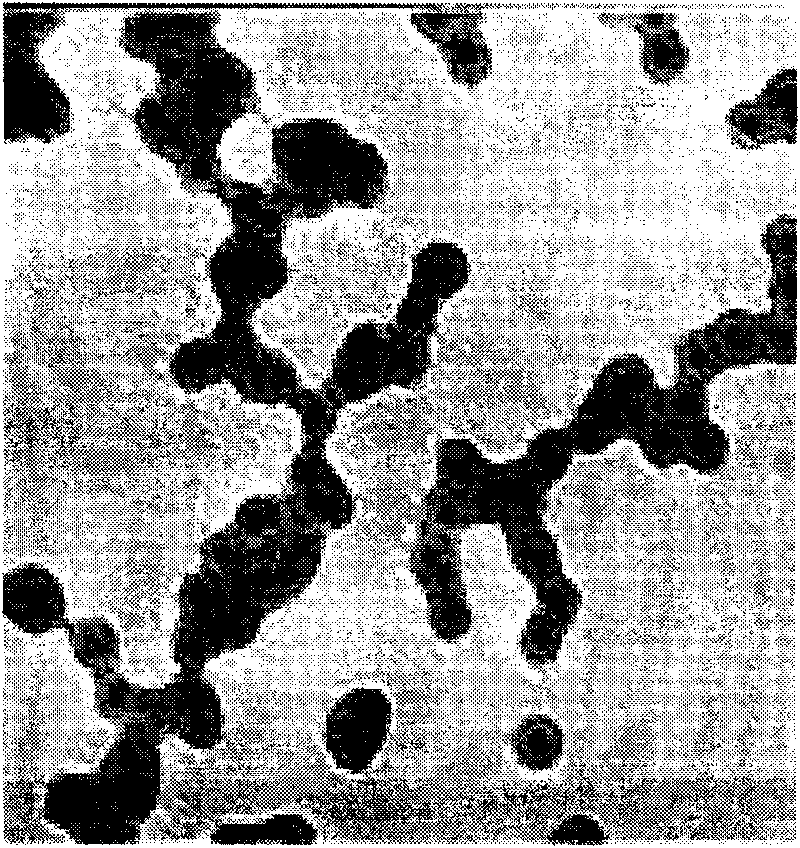

[0029] Example 2: Preparation of silica magnetic composite microspheres with a particle diameter of 80 nm and a core-shell structure.

[0030] 15 mg of iron oxide nanoparticles with a particle size of 10 nm monodispersed in water were added to a mixed solution of isopropanol and water (volume ratio 1:5), and stirred for 0.3 h at a stirring speed of 300 rpm. Add 0.5ml tetraethyl orthosilicate to the above solution, stir for 2h at a stirring speed of 400rpm, then add 2.5mL of concentrated ammonia water, continue stirring for 12h, and use an external magnetic field to remove the silica magnetic composite microspheres with a core-shell structure from the solution The supernatant was discarded, the silica magnetic composite microspheres were washed with ultrapure water and absolute ethanol, and dispersed in water. The silica magnetic composite microspheres with a core-shell structure with a particle size of 80nm are obtained, and the electron microscope characterization of the micr...

Embodiment 3

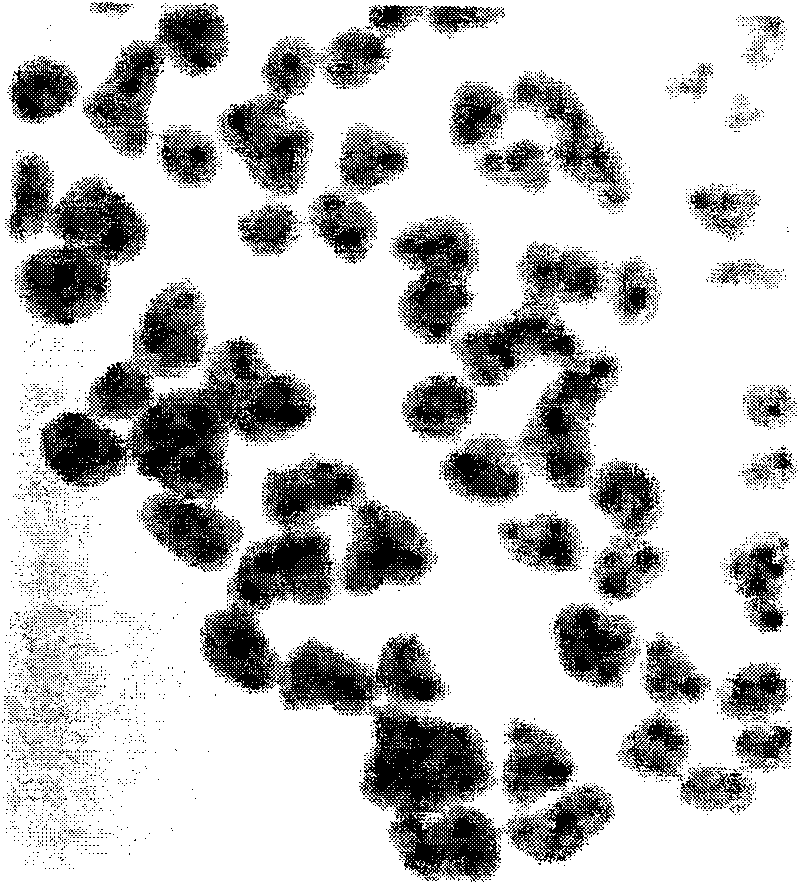

[0031] Example 3: Preparation of silica magnetic composite microspheres with a particle diameter of 100 nm and a core-shell structure.

[0032]Add 15 mg of iron oxide nanoparticles with a particle size of 12 nm monodisperse in water to a mixed solution of ethanol and water (volume ratio 1:3), then add 0.5 g of PVP10K, stir for 0.5 h, and the stirring speed is 300 rpm . Add 1 ml of methyl orthosilicate to the above solution, stir for 2 h at a stirring speed of 600 rpm, then add 3 mL of concentrated ammonia water, and continue stirring for 4 h to prepare silica magnetic composite microspheres with a core-shell structure. The silica magnetic composite microspheres with a core-shell structure are separated from the solution by an external magnetic field, the supernatant is discarded, the silica magnetic composite microspheres are washed with ultrapure water and absolute ethanol, and dispersed in water. The electron microscope characterization of the microspheres is shown in the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com