Device and method for detecting force thermal magnetic coupling action of ferromagnetic thin film

A ferromagnetic thin film and detection device technology, which is applied in the fields of engineering materials, structural deformation and mechanical experiments, and can solve the problems of lack of influence of the working state of the thin film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

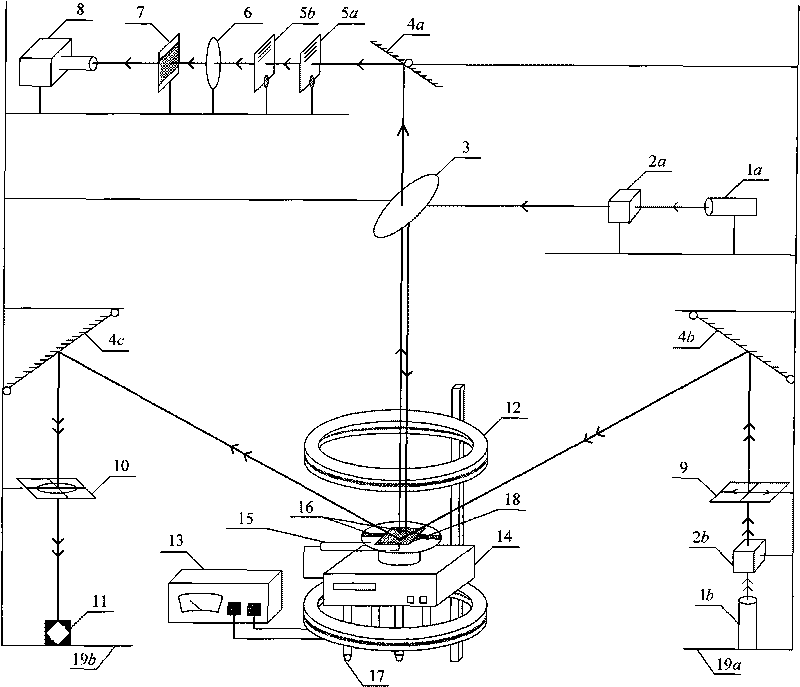

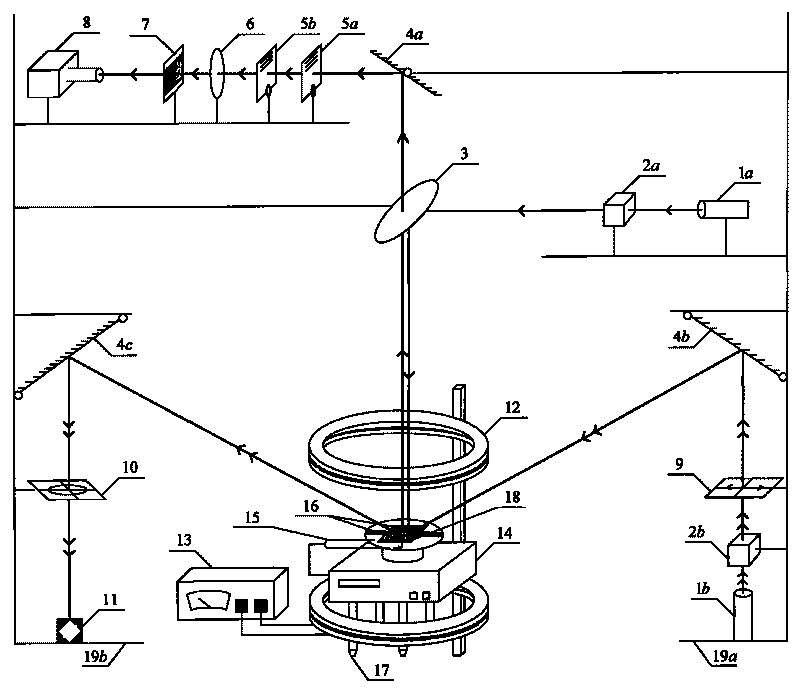

[0042] The specific structure and implementation mode of the present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention should not be limited thereby.

[0043] figure 1 It is a schematic diagram of the detection device for the force-thermo-magnetic coupling behavior of the ferromagnetic thin film of the present invention. The device includes a ferromagnetic thin film non-uniform stress measurement optical path, a thin film hysteresis loop measurement optical path, a Helmholtz coil 12 and its power supply 13, a specimen heating table 14, a thermocouple 15, a force loading structure 16 and an adjustment bracket 17, The test piece heating platform and force loading structure are arranged in the magnetic field formed by the Helmholtz coil.

[0044] The optical path for film non-uniform stress measurement includes first laser 1a, first beam expander 2a, beam splitter 3, first mirror 4a, first g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com