Epoxy terrace material and preparation method thereof

An epoxy floor and floor coating technology, applied in epoxy resin coatings, chemical instruments and methods, coatings, etc., can solve the problems of long curing time, volatilization of harmful substances, etc., and achieve high installation efficiency and enhanced impact resistance. The effect of performance and tensile strength, easy installation and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] First, prepare two components of floor coating respectively, wherein the weight percentage of component A is: 45% epoxy resin E-44 (produced by Zhejiang Jiahua Group Co., Ltd.), 30% talc, 15% epoxy resin Butyl glycidyl ether (diluent), 3% nitrile rubber with carboxyl end groups (toughening agent), 0.3% polyacrylate copolymer (leveling agent), 0.3% polyorganosiloxane ( anti-foaming agent), 2.4% polydimethylsiloxane (anti-scratch agent), and 4% colorant. The weight percentage of component B is composed of: 85% polyamide 300 type (amine value 305mgKOH / 100g, viscosity 6~20pa.s / 25℃) (curing agent) and 15% 2,4,6-tris(dimethyl) Aminomethyl)phenol (curing accelerator). The A component and the B component are mixed in a weight ratio of 10:3 to prepare a floor coating.

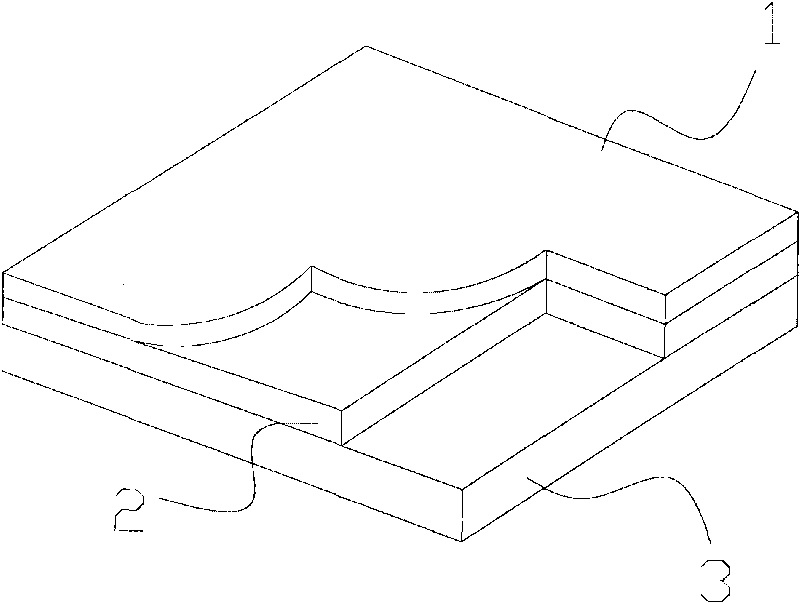

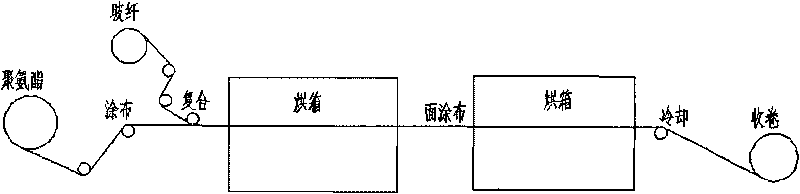

[0044] Use a coating machine to evenly coat the floor coating on polyurethane synthetic leather (thickness 0.5mm, elastic modulus 200kg / cm 2 ), and then compounded with glass fiber cloth (thickness 0.6mm), and...

Embodiment 2

[0046]First, prepare two components of floor coating respectively, wherein the weight percentage of component A is: 40% epoxy resin E-51 (produced by Zhejiang Jiahua Group Co., Ltd.), 30% talcum powder, 15% epoxy resin Butyl glycidyl ether (diluent), 5% liquid nitrile rubber (toughening agent), 0.5% polyether modified silicone oil (leveling agent), 0.2% silicone (defoamer), 4.3% of polydimethylsiloxane (anti-scratch agent) and 5% colorant. The weight percent composition of component B is: 85% 300 type (amine value 305mgKOH / 100g, viscosity 6-20pa.s / 25°C) (curing agent) and 15% benzyl dimethylamine (curing accelerator). Mix A component and B component in a weight ratio of 10:5 to prepare a floor coating

[0047] The floor coating was evenly coated on polyurethane synthetic leather (thickness 0.8mm, elastic modulus 250kg / cm) using a coating machine 2 ), then compounded with glass fiber cloth (thickness 0.2mm), and then evenly coated the above floor coating on the glass fiber cl...

Embodiment 3

[0049] First, prepare two components of floor coating respectively, wherein the weight percentage of component A is: 50% epoxy resin E-51 (produced by Zhejiang Jiahua Group Co., Ltd.), 20% talc, 15% epoxy resin Monofunctional aromatic glycidyl ether (diluent), 5% liquid nitrile rubber (toughening agent), 0.8% polyether modified silicone oil (leveling agent), 0.2% silicone (defoamer) , 4.0% polyether modified polydisiloxane (anti-scratch agent) and 5% color paste. The weight percentage of component B consists of: 90% modified alicyclic amine curing agent (amine value 400-600mgKOH / 100g, viscosity 300-600mpa.s / 25℃) and 10% benzyldimethylamine (curing accelerator) ). The A component and the B component are mixed in a weight ratio of 10:5 to prepare a floor coating.

[0050] Use a coating machine to evenly coat the floor coating on polyurethane synthetic leather (thickness 1mm, elastic modulus 300kg / cm 2 ), and then compounded with glass fiber cloth (thickness 0.4mm), and then e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com