Preparation method of hydroxymethyl substitutent o-alkyl biphenyl and intermediate thereof

A technology of alkyl biphenyl and hydroxymethyl, applied in the field of preparation of hydroxymethyl substituted o-alkyl biphenyl and its intermediates, can solve the problems of long route, high production cost, lack of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0098] The preparation method of halogenated o-alkyl biphenyl intermediate of the present invention comprises the steps:

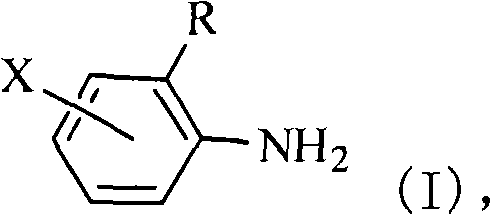

[0099] (a) providing the halogenated o-alkylaniline shown in formula (I) as raw material:

[0100]

[0101] where R is C n h 2n+1 , n=1, 2, 3, 4, or 5;

[0102] X is F, Cl, Br, or I;

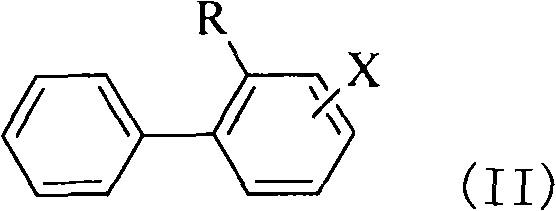

[0103] (b) In the presence of metal catalysts, acid cocatalysts and nitrite esters, the halogenated o-alkylanilines of the formula (I) of step (a) carry out diazo coupling reactions with benzene to obtain formula (II) ) of halogenated o-alkylbiphenyl compounds:

[0104]

[0105] Wherein R and X in formula (II) have the same meanings as formula (I).

[0106] In the above diazo coupling reaction, the amino group in the compound of formula (I) is coupled by diazo to obtain the compound of formula (II).

[0107] In a preferred example, the halogenated o-alkylaniline of the formula (I) is 3-chloro-2-methylaniline; the halogenated o-alkylbiphenyl compound of the formul...

Embodiment 1

[0152] Put 3-chloro-2-methylaniline (71g, 0.5mol) and benzene (300ml, 3.38mol) into a 1000ml four-necked flask, and start stirring. Ferric chloride (2g, 0.012mol), triethyl orthoformate Ester (55g, 0.34mol) was put into the reactor. The oil bath controlled the reaction temperature at 40°C, and isopropyl nitrite (80g, 0.9mol) and benzene (200mL, 2.25mol) were added to the constant pressure dropping funnel , under the condition of maintaining a constant reaction temperature of 40°C, drop it into the reactor. After the dropwise addition of isopropyl nitrite, stir at 40°C for 2 hours. Cool down to room temperature, drop in urea (50g) and 30% hydrochloric acid (200g) After phase separation, the organic layer was rectified. Recover benzene first, and then continue rectifying to obtain the refined product 3-chloro-2-methylbiphenyl (76g, 0.37mol). The gas chromatography analysis purity is 99.5%, and the yield is 75%.

Embodiment 2~ Embodiment 9

[0154] Metal catalyst consumption or kind are changed, and other is with embodiment 1, and its result is shown in Table 1

[0155] Table 1

[0156] implement

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com