Method for producing graphene

A graphene and graphite technology, which is applied in the preparation of the latest two-dimensional nano-carbon material-graphene, can solve problems such as the destruction of the crystal structure of graphite, and achieve the effects of expanding the scale, improving the grinding and peeling effect, and facilitating the scale.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

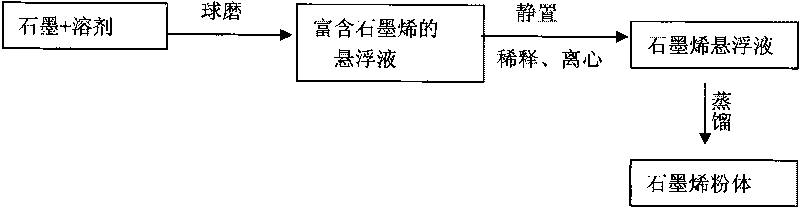

Method used

Image

Examples

Embodiment 1

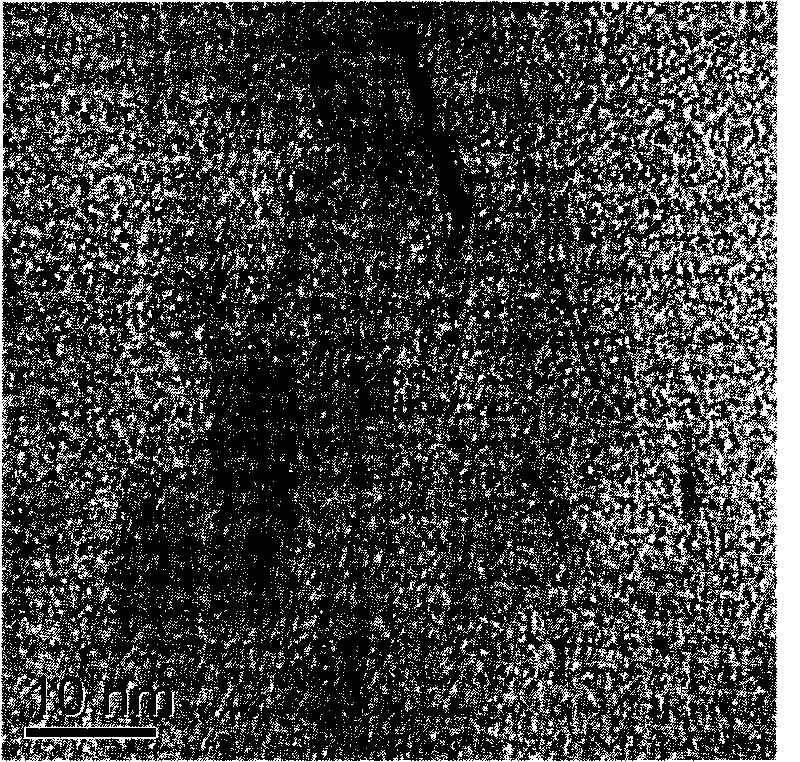

[0030]A kind of method for producing graphene, realizes by following scheme: Accurately take by weighing 0.1g of expanded graphite micropowder, it is uniformly dispersed in 320mL N by mechanical agitation, in N-dimethylformamide, forms graphite suspension, this graphite After the suspension is evenly divided into 4 parts, each part is put into a 100mL polytetrafluoroethylene ball milling jar with zirconia balls coated with polytetrafluoroethylene with a thickness of about 1mm on the surface. The weight ratio of zirconia balls of vinyl fluoride to expanded graphite powder is about 10000:1, and four polytetrafluoroethylene ball milling tanks filled with zirconia balls wrapped with polytetrafluoroethylene and expanded graphite powder suspension are symmetrical Put it into a planetary mill and ball mill for 30 hours at a speed of 300 rpm. Pour the ball-milled graphite suspension into a beaker and let it stand for 40 hours, take out the suspended part and add N, N-dimethylformamide...

Embodiment 2

[0032] A method for producing graphene, realized by the following scheme: Accurately weigh 0.25g of flake graphite micropowder, uniformly disperse it in 320mL N-methylpyrrolidone by mechanical stirring, form a graphite suspension, divide this graphite suspension on average After 4 parts, each part is put into a 100mL polytetrafluoroethylene ball milling tank together with alumina balls coated with nylon with a thickness of about 1.2mm on the surface, and alumina balls and scales wrapped with nylon on the surface The weight ratio between the graphite micropowders is about 6000:1, and four ball milling tanks containing nylon-wrapped alumina balls and flake graphite micropowder suspensions are symmetrically placed in a planetary mill and ball milled at a speed of 320 rpm for 40 Hour. Pour the ball-milled graphite suspension into a beaker and let it stand for 30 hours, take out the suspended part and add N-methylpyrrolidone to it to dilute until the aggregates are all dispersed. ...

Embodiment 3

[0034] A method for producing graphene, realized by the following scheme: accurately take 0.25g of highly oriented graphite powder, and uniformly disperse it in 320mL tetramethylurea by mechanical stirring to form a graphite suspension, and divide the graphite suspension into After 4 parts, each part is packed into a PTFE ball mill jar with a volume of 100mL together with agate balls coated with EVA with a thickness of about 1.2mm on the surface, and agate balls wrapped with EVA on the surface and highly oriented graphite The weight ratio between the powders is about 4500:1, and four polytetrafluoroethylene ball milling tanks equipped with agate balls coated with EVA on the surface and suspensions of highly oriented graphite powder are symmetrically placed in the planetary mill at 350 rpm The rotating speed ball milled for 50 hours. Pour the ball-milled graphite suspension into a beaker and let it stand for 24 hours, take out the suspended part and add tetramethylurea to it fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com