Method for manufacturing jack cylinder of hydraulic support frame

A manufacturing method and hydraulic support technology, which is applied in the welding field of hydraulic support jack cylinders, can solve the problems of cumbersome welding and leakage of two welding seams, reduce welding seams, reduce the probability of welding seam leakage, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

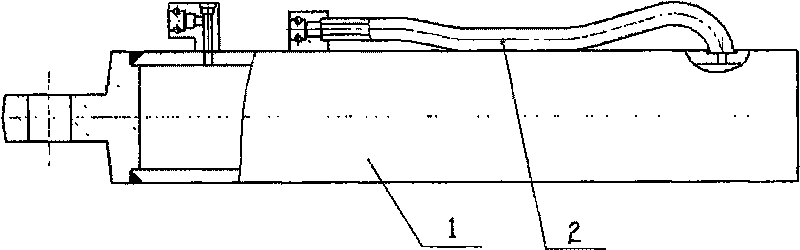

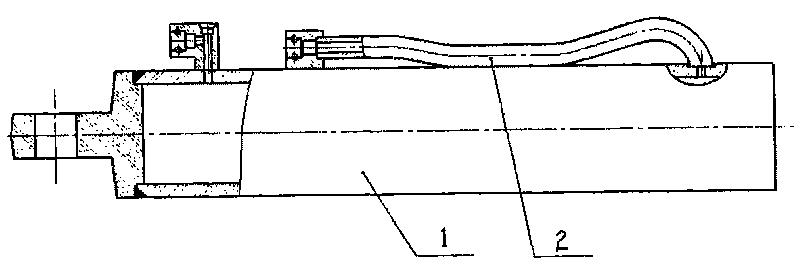

[0014] As shown in the figure, the manufacturing method of hydraulic support jack oil cylinder of the present invention, it comprises the following steps:

[0015] The first step: process the seamless steel pipe into the jack cylinder 1 according to the design size, and process the liquid opening on it;

[0016] Step 2: After the seamless steel pipe is processed into a straight pipe according to the design size of the liquid pipe, one end is subjected to arc bending treatment, that is, the liquid pipe 2 is processed into an arc with a radius of R35mm, so that the port of the liquid pipe 2 is in line with the The size and shape of the liquid port on the jack cylinder 1 match;

[0017] Step Three: Adopt CO 2 For gas shielded welding, choose welding machine NBC-500, use ER50-6 welding wire with a diameter of φ1.2mm, choose welding current 200A, weld the liquid pipe 2 directly on the jack cylinder 1 in the flat welding position, and weld the welding angle to be 6mm high. There w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com