Desulfuration method by directly utilizing magnesium slags in circulating fluidized bed boiler

A circulating fluidized bed, magnesium slag technology, applied in chemical instruments and methods, separation methods, process efficiency improvement and other directions, can solve the problems of high atomization system requirements, clogging, removal efficiency and low utilization rate of desulfurizers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0025] 1. Directly adopt the original magnesium slag as a desulfurizer, and the particle size is crushed to 1mm;

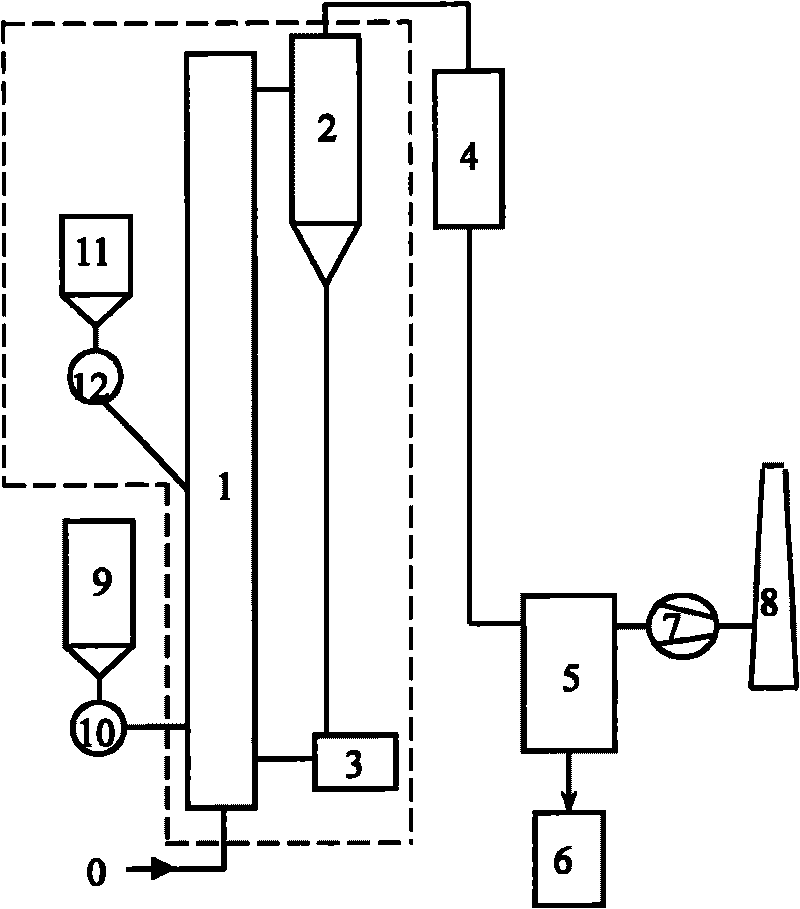

[0026] II. The desulfurization device used mainly includes a circulating fluidized bed boiler furnace 1, a cyclone separator 2, a circulating material control valve 3, a magnesium slag bin 11 and a magnesium slag feeder 12;

[0027] III. The circulating fluidized bed boiler has a capacity of 220t / h. Furnace 1 has a rectangular cross-section with a cross-sectional size of 5160×8680mm. The height of the furnace is 32000mm. Water-cooled walls are arranged around the heating surface. The combustion temperature in the furnace is 930°C; the cyclone separator 2 is To achieve high-temperature gas-solid separation, the separator adopts a water-cooled cyclone separator with a wear-resistant layer. It is designed according to the design specifications of the high-efficiency separator. The inner diameter of the two separators is 4850mm; the circulating material control valve 3...

Embodiment approach 2

[0040] 1. Directly adopt the original magnesium slag as a desulfurizer, and the particle size is crushed to 0.005mm;

[0041] II. The desulfurization device used mainly includes a circulating fluidized bed boiler furnace 1, a cyclone separator 2, a circulating material control valve 3, a magnesium slag bin 11 and a magnesium slag feeder 12;

[0042] III. The circulating fluidized bed boiler has a capacity of 410t / h. Furnace 1 has a rectangular cross-section with a cross-sectional size of 13810×6770mm. The height of the furnace is 34900mm. Water-cooled walls are arranged around the heating surface. The combustion temperature in the furnace is 897°C; cyclone separator 2 is due to To achieve high-temperature gas-solid separation, the separator adopts a water-cooled square cyclone separator with a wear-resistant layer. The cross-section of the two separators is 6910mm×6910mm; the circulating material control valve 3 is used to realize the return of the material, and the J-type valv...

Embodiment approach 3

[0055] The particle size is crushed to 0.5 mm, and the combustion temperature in the furnace is 850° C. Others are the same as Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com