Method for preparing nano tricalcium phosphate silk protein complex three-dimensional porous material

A three-dimensional porous, tricalcium phosphate technology for application in the field of medical materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

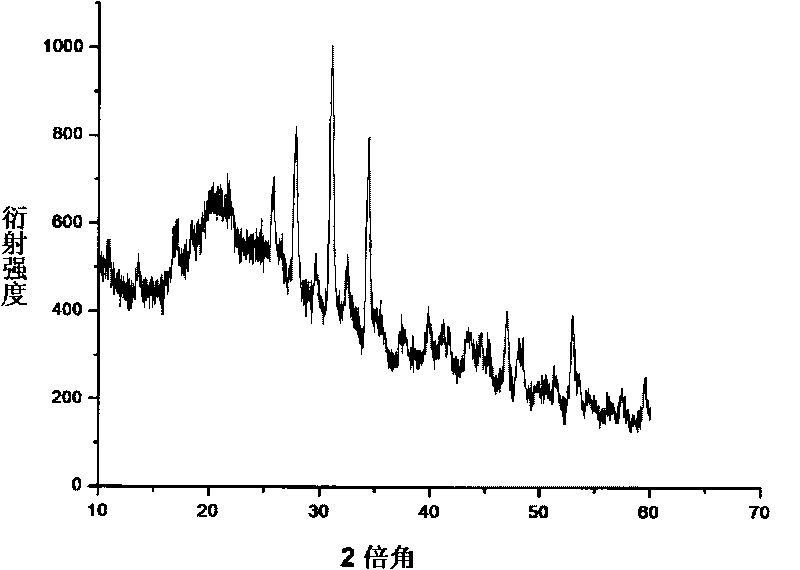

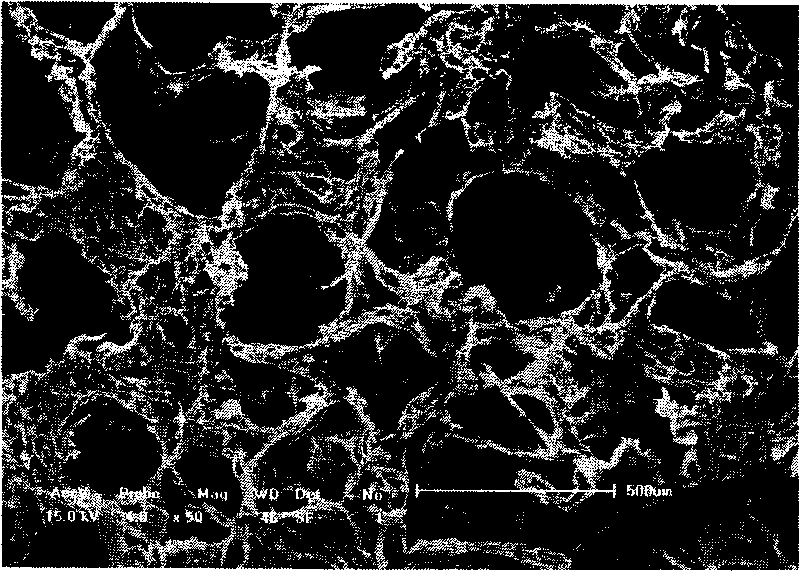

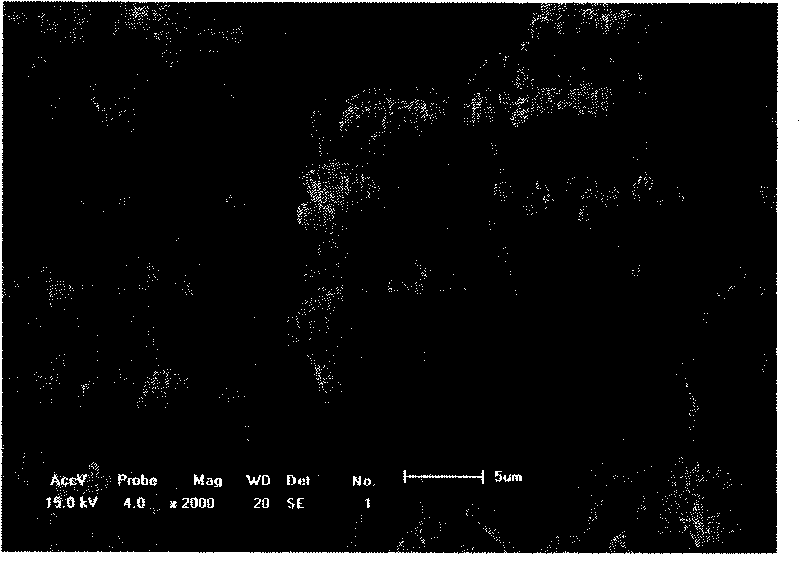

[0014] A method for preparing a composite three-dimensional porous bone tissue engineering scaffold. The specific steps are: adding β-tricalcium phosphate with a particle size of 100-300nm to 1ml of n-butanol at a mass volume ratio of 3.6g:100ml, and mechanically rotating at 500rpm. Stir and carry out ultrasonic dispersion at the same time. The ultrasonic power is 180W and the frequency is 50KHz; The mass ratio of the mixture is 10:100, mechanically stirred at 200rpm for 1min; adding sodium chloride particles with a particle size of 350-500μm as a pore-forming agent, adding sodium chloride particles with a mass of 24g, placing them at room temperature for 24 hours, adding Soak in water for 24 hours to elute the pore-forming agent. The weight ratio of sodium chloride particles to water is 1g:40ml; after the pore-forming agent is washed, freeze-dry to obtain a composite three-dimensional porous bone tissue engineering scaffold.

[0015] The porous composite scaffold prepared by ...

Embodiment 2

[0017] A method for preparing a composite three-dimensional porous bone tissue engineering scaffold. The specific steps are: adding β-tricalcium phosphate with a particle size of 100-300nm to 1ml of n-butanol at a mass-volume ratio of 30:100, and mechanically stirring at a speed of 500rpm At the same time, ultrasonic dispersion was carried out, the ultrasonic power was 180W, and the frequency was 50KHz; after 5 minutes, the above dispersion liquid was added dropwise to 6ml of silk fibroin solution with a mass fraction of 10%, to control the separation of β-tricalcium phosphate and silk fibroin. The mass ratio is 50:100, mechanically stirred at 200 rpm for 1 min; adding sodium chloride particles with a particle size of 350-500 μm as a pore-forming agent, adding 24 grams of sodium chloride particles, and placing them at room temperature for 24 hours. Add water and soak for 24 hours to elute the pore-forming agent. The weight ratio of sodium chloride particles to water is 1g:40ml;...

Embodiment 3

[0020] A method for preparing a composite three-dimensional porous bone tissue engineering scaffold. The specific steps are: adding β-tricalcium phosphate with a particle size of 100-300nm in a mass-to-volume ratio of 24g:100ml into 1ml of n-butanol, mechanically stirring at a speed of 500rpm and At the same time, carry out ultrasonic dispersion, the ultrasonic power is 180W, and the frequency is 50KHz; after 5 minutes, the above dispersion liquid is added dropwise to 6ml of silk fibroin solution with a mass fraction of 8%, to control the quality of β-tricalcium phosphate and silk fibroin The ratio is 30:100, mechanical stirring at 200rpm speed for 1min; add sodium chloride particles with a particle size of 350-500μm as a pore-forming agent, the quality of the added sodium chloride particles is 24g, and after 24 hours at room temperature, add water Soak for 24 hours to elute the pore-forming agent. The weight ratio of sodium chloride particles to water is 1g:40ml; after the por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com