Nanometer ZnO anti-bacterial and anti-fouling coating and method for preparing same

A nano-zinc oxide, zinc oxide modification technology, applied in antifouling/underwater coatings, polyester coatings, polyurea/polyurethane coatings, etc. Universal type, attenuation of antibacterial effect, etc., to achieve the effect of outstanding anti-fouling ability, high surface activation energy, and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

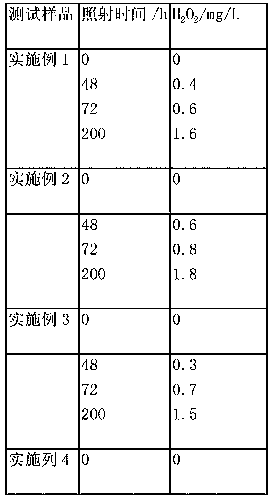

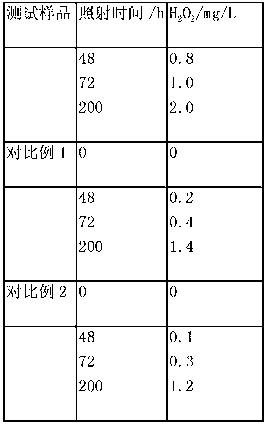

Examples

Embodiment 1

[0039] Dissolve 2g of diammonium hydrogen citrate in 158g of deionized water, start stirring, and slowly pour 40g of nano-zinc oxide particles with a particle size of 30nm into deionized water. After oscillating, the aqueous solution was poured into a Netzsch MiniCer grinder, controlled at a speed of 2500-3000 rpm, ground and stirred for 160 min, and then vacuum-dried until constant weight. Put 40g of dried surface-functionalized nano-zinc oxide, 3g of hypericin, 19.6g of methyl isobutyl ketone, and 17.1g of xylene into a Netzsch ShearMaster grinder, and grind and stir at a controlled speed of 250-350rpm , then add rosin 10g, acrylic resin 6.2g, commercially available epoxidized linseed oil Flexol LOE1.5g, commercially available MPA 2000X 0.6g, white carbon black 0.4g, oily dye 1.6g. Continue stirring for 70 minutes to obtain the nano zinc oxide antibacterial and antifouling coating.

Embodiment 2

[0041] Dissolve 2g of 1,2-dihydroxy-3,5-sodium disulfonate in 91g of deionized water, start stirring, slowly add 40g of nano-zinc oxide particles with a particle size of 30nm into deionized water and stir for 2 hours, then add 5g of Disperbyk190 Then ultrasonically oscillate for 4.5 hours under the ultrasonic instrument, then pour the oscillated aqueous solution into the NetzschMiniCer grinder, control the rotation speed at 2500-3000rpm, grind for 160min, and then vacuum dry until constant weight. Put 23.4g of dried surface-functionalized nano-zinc oxide, 1.5g of commercially available surfactant 5103, 1g of hypericum anthrone, and 40.4g of purified water into a Netzsch ShearMaster grinder, stir at a speed of 250-350rpm, and then add Hydroxyethyl cellulose 0.5g, water-soluble polyester-urethane resin 24g, dimethylaminoethanol (DMEA) 1g, hexamethoxymethylmelamine (HMMM) 6.3g, p-toluenesulfonamide 0.3g, water-soluble dye 1.6g , and stirred for 30 minutes to obtain the nanometer ...

Embodiment 3

[0043] Dissolve 2.4g of 2-(2-(2-methoxyethoxy)ethoxy)acetic acid in 14g of ethylene glycol isopropyl ether; after starting stirring, slowly add 40g of nano-zinc oxide particles with a particle size of 30nm Stir and mix for 30 minutes, then pour the zinc oxide slurry into an electronically controlled three-roller (EXAKT 80E), add 77g of ethanol while stirring, and then ultrasonically vibrate the nano-zinc oxide-ethanol solution under the ultrasonic instrument for 2.5 hours, and shake Finally, the nano-zinc oxide-ethanol solution was poured into the Netzsch MiniCer grinder at a speed of 2500-3000 rpm, grinded for 160 min, and then vacuum-dried until constant weight. Put 40 g of dried surface-functionalized nano-zinc oxide, 19.6 g of methyl isobutyl ketone, and 17.1 g of xylene into a Netzsch ShearMaster grinder, stir at a controlled speed of 250-350 rpm, add 10 g of rosin, and 6.2 g of acrylic resin in turn. g, commercially available Flexol LOE 1.5g, commercially available MPA 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com