Preparation method of flame retardant polypropylene material

A technology for flame-retardant polypropylene and polypropylene, applied in fibrous fillers, dyed low-molecular-weight organic compounds, etc., can solve the flame-retardant properties of unreported composite materials such as oxygen index, and the effect of oxygen index is not obvious, and can only reach 32.5 And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

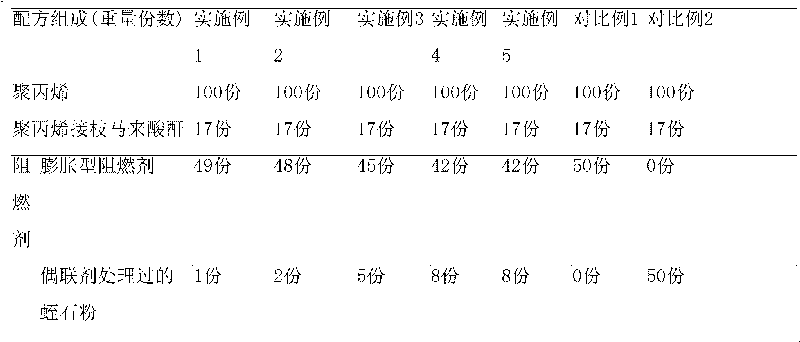

Embodiment 1-4

[0019] (1) Dissolve 100 parts of titanate coupling agent in 100 parts of solvent oil to make a titanate coupling agent solution, add 3 parts of titanate coupling agent solution to 100 parts of vermiculite powder in a high-speed mixer Mix at a high speed for 15 minutes at 110° C. to obtain surface-coupling-treated vermiculite powder.

[0020] (2) According to the formula in Table 1, the components were uniformly mixed and then melt-blended in an internal mixer at 190° C. and 100 rpm for 6 minutes to obtain a flame-retardant polypropylene material. The obtained material performance test results are shown in Table 2.

Embodiment 5

[0022] The surface treatment process of vermiculite is with embodiment 1-4.

[0023] According to the formula in Table 1, after mixing the components evenly, the mixed material is added to a parallel co-rotating twin-screw extruder for blending and extruding to obtain a flame-retardant polypropylene material. The extrusion process is 180°C in the first zone and 190 in the second zone. ℃, the third zone is 200℃, the fourth zone is 195℃, the screw speed is 260r / min, and the feeding frequency is 20Hz. The performance test results of the obtained materials are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com