Method for preparing crystalline V-type ammonium polyphosphate with phosphoric acid

A technology of ammonium polyphosphate and phosphoric acid, applied in the field of ammonium phosphate, can solve problems such as harsh operating conditions and difficult realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

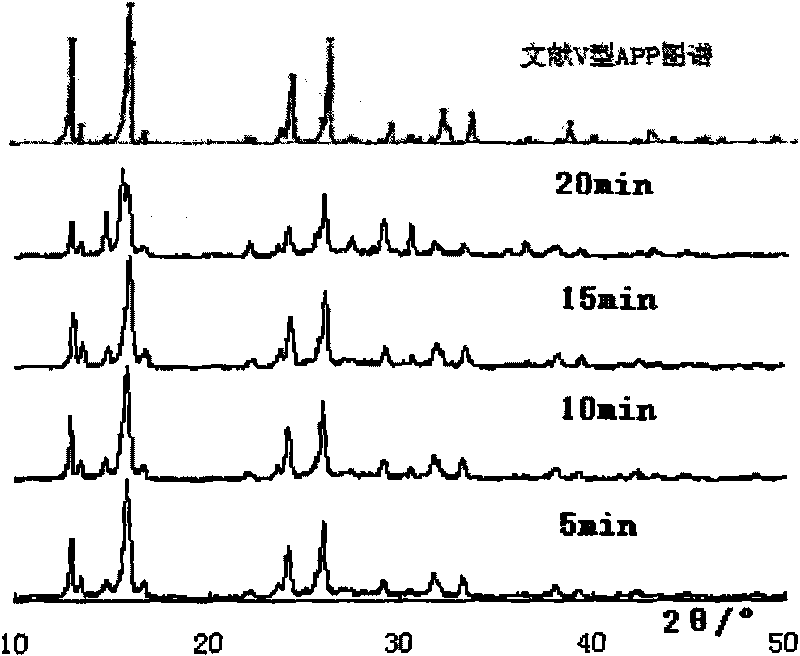

[0048] After heating 25.14 milliliters of phosphoric acid (85%) to 300°C, cool down to 180°C to remove a certain amount of water, and keep stirring during this period; then add 8.14 grams of melamine into the reactor, continue to heat up to about 320°C for thermal condensation, and keep After 15 minutes, pass through dry ammonia for ammoniation, keep the temperature in the range of 240-280°C, ammonia flow rate 0.5L / min, ammoniation for 30 minutes, stir and crush and discharge; the XRD pattern of this product is very similar to the literature pattern, please refer to attached Figure 5 .

Embodiment 2

[0050]After heating 25.14 milliliters of phosphoric acid (85%) to 260°C, cool down to 180°C to remove a certain amount of water, and keep stirring during this period; then add 8.14 grams of melamine into the reactor, continue to heat up to about 330°C for thermal condensation, and keep After 10 minutes, pass through dry ammonia for ammoniation, keep the temperature in the range of 240-280°C, ammonia flow rate 0.5L / min, ammoniation for 30 minutes, stir and crush and discharge; the XRD pattern of this product is very similar to the literature pattern, please refer to attached Figure 6 .

Embodiment 3

[0052] After heating 100.56 milliliters of phosphoric acid (85%) to 300°C, cool down to 180°C to remove a certain amount of water, stirring constantly; then add 32.56 grams of melamine to the reactor, continue to heat up to about 310°C for thermal condensation, and keep After 5 minutes, pass through dry ammonia for ammoniation, maintain the temperature within the range of 240-280°C, ammonia flow rate 0.5L / min, ammoniation for 30 minutes, stir and crush and discharge; the XRD pattern of this product is highly similar to the literature pattern, please refer to the attached Figure 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com