Method for preparing glass microfibre reinforcement nano-hydroxyapatite biological composite coating

A technology of nano-hydroxyapatite and glass microfibers, which is applied in the direction of coating, etc., can solve the problem of low bonding force between coatings and coatings, and achieve the effect of improving the bonding strength and stabilizing the crystal phase of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

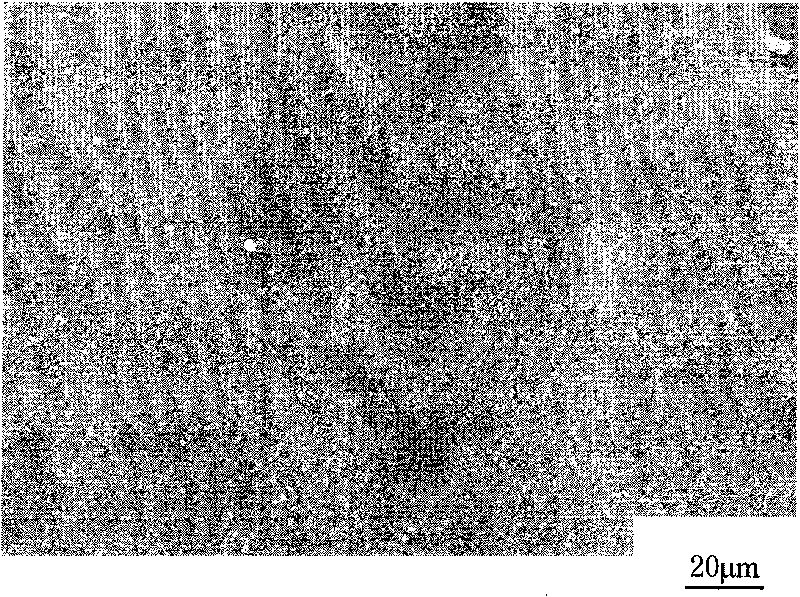

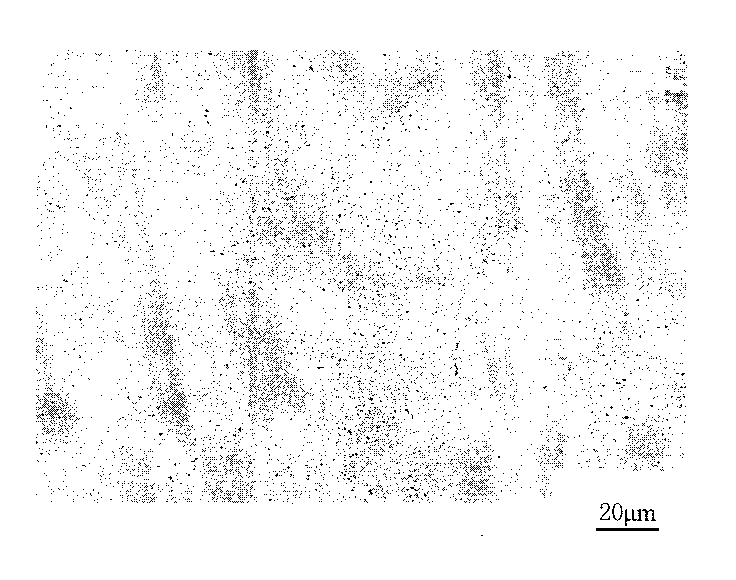

Image

Examples

Embodiment 1

[0022] Example 1: 1) Preparation of nano-hydroxyapatite powder

[0023] First, we will analyze pure Ca(NO 3 ) 2 ·4H 2 O and (NH 2 ) 2 HPO 4 Mix according to the molar ratio of calcium to phosphorus of 1:1.57, then add distilled water to dissolve, so that the Ca in the solution 2+ The ion concentration is 0.04mol / L; then in the solution according to Ca(NO 3 ) 2 ·4H 2 O and (NH 2 ) 2 HPO 4 Total mass: urea = 1:5, add urea powder to make a mixed liquid, stir it evenly; under magnetic stirring, put the generator head of the multi-frequency sonochemical generator into the above mixed liquid, respectively under 100w ultrasonic power Sonochemical synthesis at 40°C for 1.5 hours, and then heating to 70°C for 2 hours; after filtering off the suspension, wash with distilled water and then with absolute ethanol. Put the filtered material in a vacuum drying oven at 80°C Drying to obtain nano-hydroxyapatite powder, namely nano-Hap powder;

[0024] 2) Preparation of glass short fibers

[0025] Ta...

Embodiment 2

[0030] Example 2: 1) Preparation of nano-hydroxyapatite powder

[0031] First, we will analyze pure Ca(NO 3 ) 2 ·4H 2 O and (NH 2 ) 2 HPO 4 Mix according to the molar ratio of calcium to phosphorus of 1:1.67, and then add distilled water to dissolve it to make the Ca in the solution 2+ The ion concentration is 0.08mol / L; then in the solution according to Ca(NO 3 ) 2 ·4H 2 O and (NH 2 ) 2 HPO 4 Total mass: urea = 1:6, add urea powder to make a mixed solution, stir it evenly; under magnetic stirring, put the generator head of the multi-frequency sonochemical generator into the above-mentioned mixed solution, respectively under the ultrasonic power of 200w Sonochemical synthesis at 40°C for 1.5 hours, and then heating to 70°C for 2 hours; after filtering off the suspension, wash with distilled water and then with absolute ethanol. Put the filtered material in a vacuum drying oven at 80°C Drying to obtain nano-hydroxyapatite powder, namely nano-Hap powder;

[0032] 2) Preparation of gl...

Embodiment 3

[0038] Example 3: 1) Preparation of nano-hydroxyapatite powder

[0039] First, we will analyze pure Ca(NO 3 ) 2 ·4H 2 O and (NH 2 ) 2 HPO 4 Mix according to the molar ratio of calcium to phosphorus of 1:1.77, then add distilled water to dissolve, so that the Ca in the solution 2+ The ion concentration is 0.12mol / L; then in the solution according to Ca(NO 3 ) 2 ·4H 2 O and (NH 2 ) 2 HPO 4 Total mass: urea = 1:7, add urea powder to make a mixed solution, stir it evenly; under magnetic stirring, put the generating head of the multi-frequency sonochemical generator into the above-mentioned mixed solution, respectively under the ultrasonic power of 300w Sonochemical synthesis at 40°C for 1.5 hours, and then heating to 70°C for 2 hours; after filtering off the suspension, wash with distilled water and then with absolute ethanol. Put the filtered material in a vacuum drying oven at 80°C Drying to obtain nano-hydroxyapatite powder, namely nano-Hap powder;

[0040] 2) Preparation of glass s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com