Method for preparing CdS film in microwave hydrothermal mode

A microwave hydrothermal and thin film technology, applied in chemical instruments and methods, crystal growth, coating and other directions, can solve the problems of expensive supporting facilities, low utilization rate of raw materials, expensive equipment and instruments, etc., and achieve controllable and reduced grain growth. The effect of film production cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

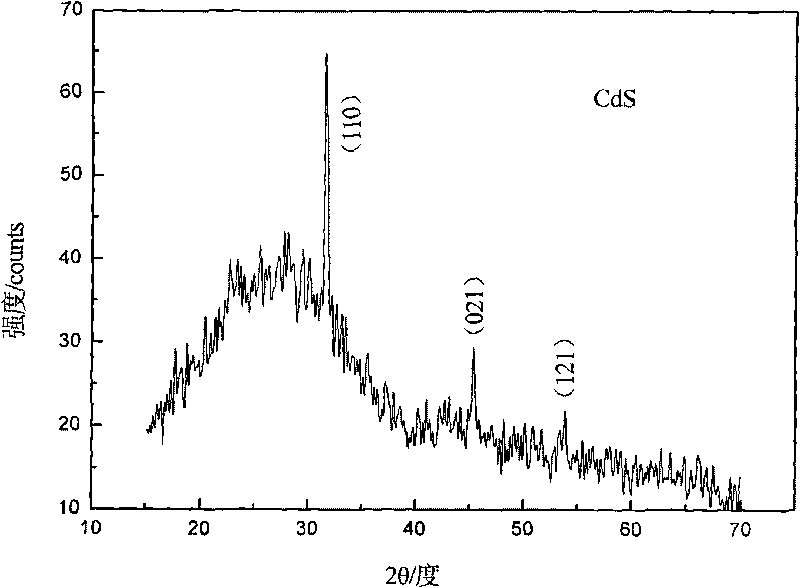

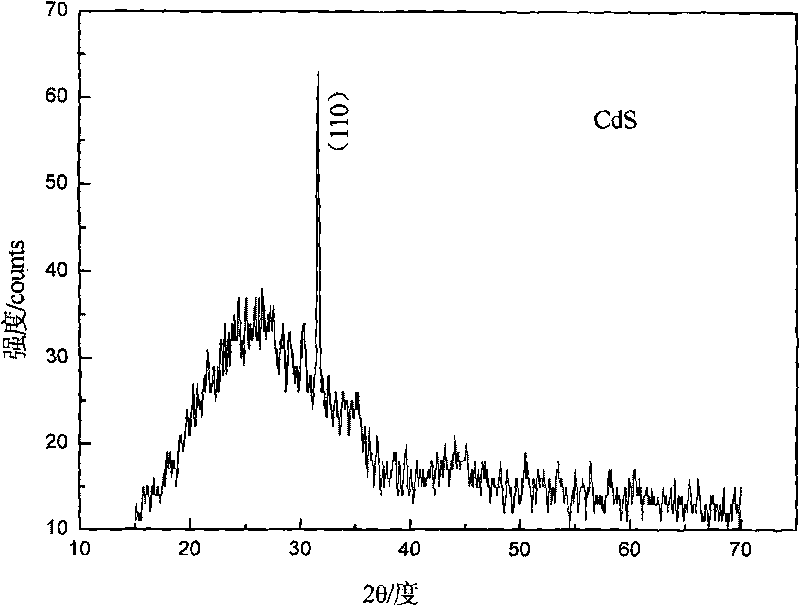

Image

Examples

Embodiment 1

[0016] Embodiment 1: 1) will analytically pure cadmium chloride monohydrate (CdCl 2 ·H 2 O) added to deionized water to make Cd 2+ A transparent solution with a concentration of 0.05mol / L, the resulting solution is denoted as A;

[0017] 2) Add analytically pure sodium thiosulfate pentahydrate (Na 2 S 2 SO 3 ·5H 2 O), making the solution Cd 2+ / S 2 SO 3 2- The molar concentration ratio of is 1: 1, and the gained solution is denoted as B;

[0018] 3) Add analytically pure EDTA (ethylenediaminetetraacetic acid) to solution B so that the concentration ratio of ethylenediaminetetraacetic acid is 0.0025mol / L, then adjust the pH value of the solution to 2.0-6.9, stir to form a homogeneous sol, Denote it as C, and use it as a coating solution for later use;

[0019] 4) Clean the substrate: ultrasonically vibrate the slide glass in water and absolute ethanol for 10 minutes respectively, mix nitric acid with a mass concentration of 70% and hydrogen peroxide with a mass conce...

Embodiment 2

[0023] Embodiment 2: 1) will analytically pure cadmium chloride monohydrate (CdCl 2 ·H 2 O) added to deionized water to make Cd 2+ A transparent solution with a concentration of 0.1mol / L, the resulting solution is denoted as A;

[0024] 2) Add analytically pure thiourea (SC(NH 2 ) 2 ), so that the Cd in the solution 2+ / :SC(NH 2 ) 2 The molar concentration ratio of is 1: 2, and the gained solution is denoted as B;

[0025] 3) Add analytically pure polyvinylpyrrolidone to solution B, so that the concentration of polyvinylpyrrolidone is 0.005mol / L, then adjust the pH value of the solution to 2.0-6.9, stir to form a uniform sol, denoted as C, as a coating Liquid standby;

[0026] 4) Clean the substrate: ultrasonically vibrate the ITO glass in water and absolute ethanol for 10 minutes respectively, mix nitric acid with a mass concentration of 70% and hydrogen peroxide with a mass concentration of 30% in a volume ratio of 1:1, and then mix the substrate Soak the slices in ...

Embodiment 3

[0030] Embodiment 3: 1) will analytically pure cadmium chloride monohydrate (CdCl 2 ·H 2 O) added to deionized water to make Cd 2+ A transparent solution with a concentration of 0.1mol / L, the resulting solution is denoted as A;

[0031] 2) Add analytically pure sodium thiosulfate pentahydrate (Na 2 S 2 SO 3 ·5H 2 O), making the solution Cd 2+ / S 2 SO 3 2- The molar concentration ratio of is 1: 4, and the gained solution is denoted as B;

[0032] 3) Add analytically pure polyvinylpyrrolidone to solution B, so that the concentration of polyvinylpyrrolidone is 0.006mol / L, then adjust the pH value of the solution to 2.0-6.9, stir to form a uniform sol, denoted as C, as a coating Liquid standby;

[0033] 4) Clean the substrate: ultrasonically vibrate the Si substrate in water and absolute ethanol for 10 minutes respectively, mix nitric acid with a mass concentration of 70% and hydrogen peroxide with a mass concentration of 30% in a volume ratio of 1:1, and then mix the sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com