Common output mirror thulium and holmium co-doped yttrium lithium fluoride single-frequency pulse laser for master and slave laser purpose

A technology of pulsed lasers and yttrium lithium fluoride, which is applied in the direction of lasers, laser devices, laser components, etc., can solve the problems of low injection efficiency and achieve low cost, small volume, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

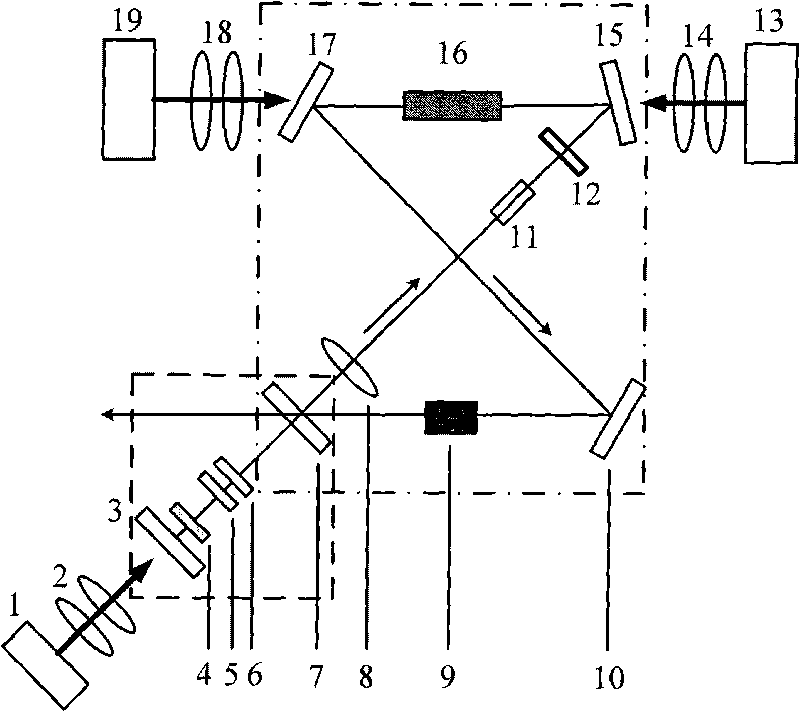

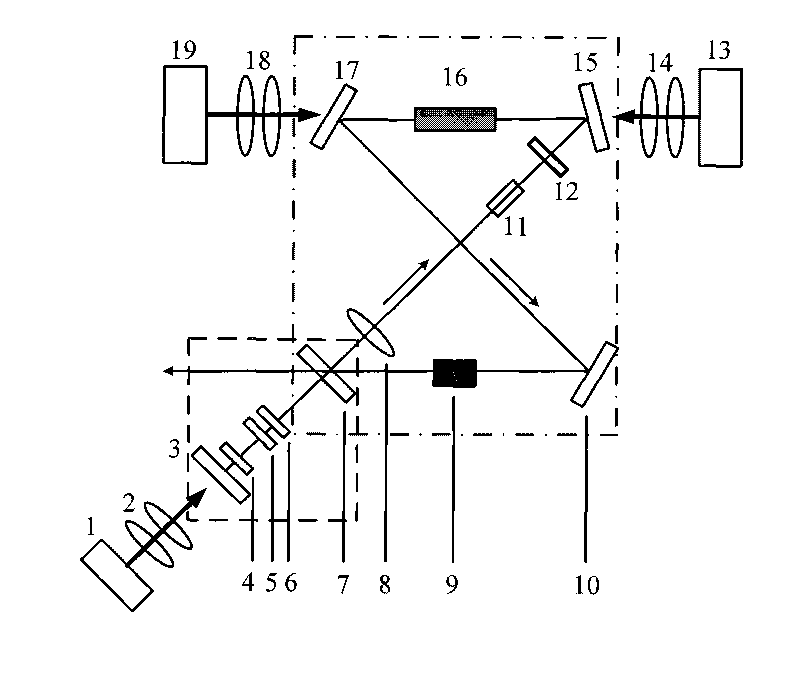

[0018] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0019] 1, the composition of this embodiment includes: laser diode first pump source 1, coupling lens group 2, main laser rear cavity mirror 3, a-axis cutting thickness of 2.5mm Thulium holmium co-doped ytterbium lithium fluoride (Tm , Ho:YLF) laser crystal 4, 1mm thick solid Fabry-Perot (F-P) etalon 5, 100μm thick solid Fabry-Perot (F-P) etalon 6, common output mirror 7, mode matching Converging lens 8, acousto-optic Q switch 9, plano-concave mirror 10, optical isolator 11, half-wave plate 12, second pump source fiber-coupled laser diode 13, coupling lens group 14, plane mirror 15, a Thulium holmium co-doped ytterbium lithium fluoride (Tm, Ho:YLF) laser crystal 16 , plane mirror 17 , coupling lens group 18 , third pumping source fiber-coupled laser diode 19 with axial cutting thickness of 5-10 mm.

[0020] The master and slave lasers share an output mirror, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com