Method for preparing p-type filling type skutterudite compound thermoelectric material

A thermoelectric material and filling technology, which is applied in the field of preparation of filled skutterudite thermoelectric compounds, can solve the problems of prolonging the preparation period and decreasing the thermoelectric performance, and achieves the effects of reducing energy consumption, reducing preparation cost and fine grain structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

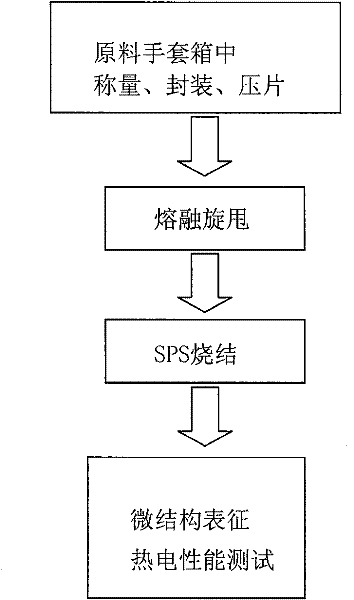

[0025] Such as figure 1 Shown, a kind of preparation method of p-type filled type skutterudite compound thermoelectric material, it comprises the steps:

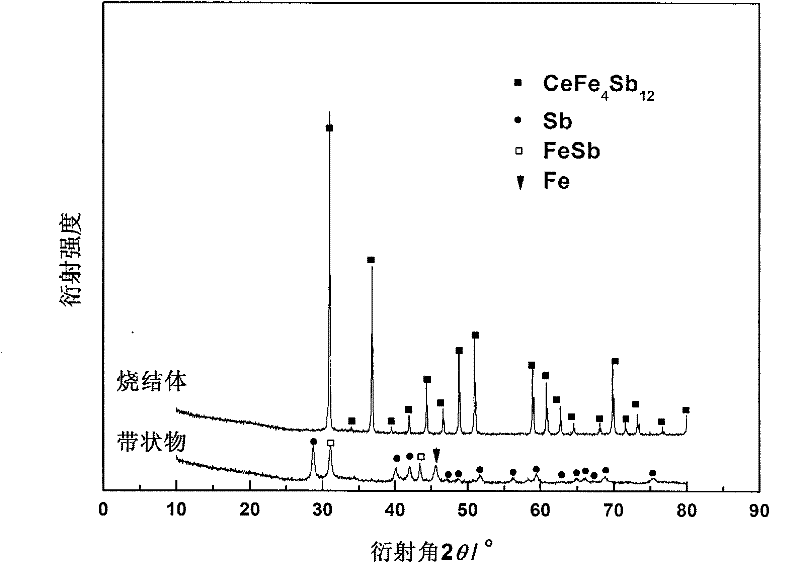

[0026] 1) With high-purity granular Ce, Fe and Sb as the starting reaction raw materials, the reaction raw materials are formulated according to the chemical formula CeFe 4 Sb 12.1 (MFe 4-x co x Sb 12+y, M is Ce, x=0, y=0.1) weighing in an Ar gas glove box, a total of 20g; high-purity granular Ce, Fe and Sb are mixed, packaged, and then pressed into a columnar block under 300MPa pressure;

[0027] The purity of high-purity granular Ce is 99.0% (mass); the purity of high-purity granular Fe is 99.99% (mass), and the purity of high-purity granular Sb is 99.999% (mass);

[0028] 2) Put the obtained columnar block into a quartz glass tube with an opening at one end and a small hole with a diameter of 0.3-1.0 mm at the other end, and then put the quartz glass tube into a single-roller quenching, melting, spinning and spinning...

Embodiment 2

[0036] A method for preparing a p-type filled skutterudite compound thermoelectric material, comprising the steps of:

[0037] 1) With high-purity granular Ce, Fe, Co and Sb as the starting reaction raw materials, the reaction raw materials are formulated according to the chemical formula CeFe 3 CoSb 12.3 (MFe 4-x co x Sb 12+y , M is Ce, x=1, y=0.3) weighed in an Ar gas glove box, and the reaction raw materials totaled 20g; high-purity granular Ce, Fe, Co and Sb were mixed, and then pressed into a columnar block under a pressure of 300MPa body;

[0038] The purity of high-purity granular Ce is 99.0% (mass); the purity of high-purity granular Fe is 99.99% (quality), the purity of high-purity granular Co is 99.99% (quality), and the purity of high-purity granular Sb is 99.999% (quality);

[0039] 2) Put the obtained columnar block into a quartz glass tube with an opening at one end and a small hole with a diameter of 0.3 to 1.0 mm at the other end, and then put the quartz ...

Embodiment 3

[0047] A method for preparing a p-type filled skutterudite compound thermoelectric material, comprising the steps of:

[0048] 1) Using high-purity granular Ce, Fe, Co and Sb as the starting reaction raw materials, the reaction raw materials are formulated according to the chemical formula CeFeCo 3 Sb 13 (MFe 4-x co x Sb 12+y , M is Ce, x=3, y=1.0,) weighed in an Ar gas glove box, the total amount of reaction raw materials is 20g; high-purity granular Ce, Fe, Co and Sb are mixed, and then pressed into a column under a pressure of 400MPa Block;

[0049] The purity of high-purity granular Ce is 99.0% (mass); the purity of high-purity granular Fe is 99.99% (quality), the purity of high-purity granular Co is 99.99% (quality), and the purity of high-purity granular Sb is 99.999% (quality);

[0050] 2) Put the obtained columnar block into a quartz glass tube with an opening at one end and a small hole with a diameter of 0.3-1.0 mm at the other end, and then put the quartz glas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com