Cell electrofusion chip device based on columnar microelectrode array and electrofusion method

A microelectrode array and electrofusion technology, which is applied in the field of chips providing cell electrofusion and devices for biological cell electrofusion, can solve the problems of weak precise control of cells, large chip spacing, inability to achieve high-throughput fusion, etc. The effect of fusion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

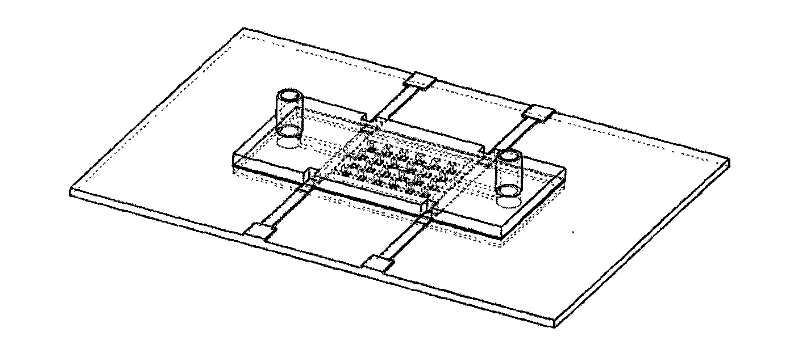

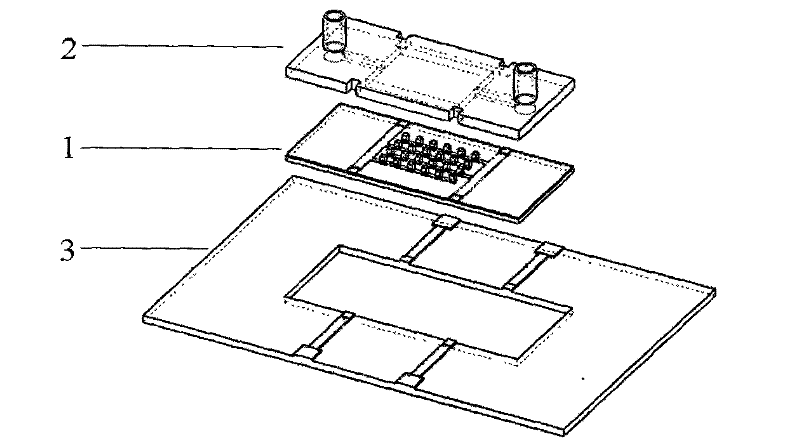

[0053] see figure 1 with figure 2 , the cell electrofusion chip device based on a columnar microelectrode array is composed of a columnar microelectrode array chip 1 , a flow path control module 2 and a peripheral printed circuit board 3 .

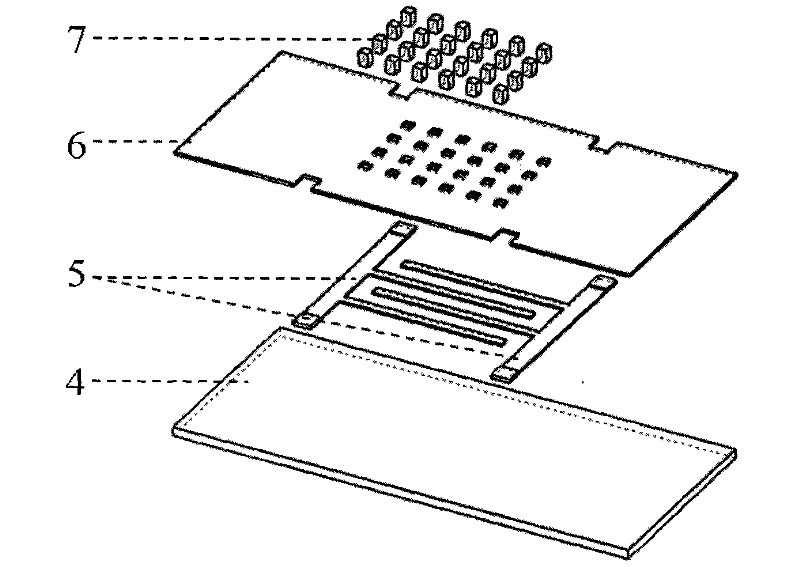

[0054] see image 3 The micro-chamber array chip 1 is composed of a quartz base layer 4, a metal wire layer 5, a polymer insulating layer 6 and a columnar micro-electrode array layer 7 in sequence from bottom to top.

[0055] see Figure 4 , the metal wire layer 5 is built on the quartz base layer 4 by micromachining technology, and is a staggered comb-shaped lead array. The material is selected from metals such as aluminum and copper with good conductivity, and the thickness is 1-3 μm. The comb-shaped lead array of the comb The width of the ridge 9 can be wider and can be controlled within the range of 100-500 μm to ensure good conductivity and reliability; the width of the comb teeth 10 is determined according to the density of the m...

Embodiment 2

[0061] Embodiment 2: the processing of each part of this device:

[0062] 1. The columnar microelectrode array chip is realized by MEMS processing technology, and the processing steps are as follows (the metal array electrode layer material described here is gold Au, and the polymer layer material is polyimide):

[0063] A. Use quartz as the substrate for processing chips;

[0064] B. Build a layer of aluminum on the quartz substrate with a thickness of 1-3 μm;

[0065] C. A comb-shaped microarray structure can be formed on the aluminum layer by photolithography to form a metal wire layer;

[0066] D. Spin-coat polyimide glue on the surface of the above structure to form a polyimide insulating layer with a thickness of 3-5 μm;

[0067] E. Photoetching polyimide to form micropores;

[0068] F. Sputter a layer of Ti / W on the aluminum surface where the photolithographic microholes are exposed, with a thickness of 50nm;

[0069] G. Electroplate a layer of gold on the surface o...

Embodiment 3

[0078] Embodiment 3: continuous flow fusion method

[0079] From the sample inlet 18 described in embodiment 1, use micropump to inject cell suspension; The wide space of the electrode array can make the cells flow freely; the sine wave electric stimulation signal is applied to the metal wire layer 5 through the peripheral printed circuit board 3, and a non-uniform gradient electric field will be formed between the opposite columnar microelectrodes, and the two electrodes between the microelectrodes Each cell will be lined up under the action of dielectrophoretic force; after the queuing is completed, a square wave pulse sequence signal is applied, and the cell pair that has completed the queuing will complete cell electroporation-cell electrofusion under the action of a high-intensity pulsed electric field between the microelectrodes Wait for the process. After the cell electrofusion process is completed, combined with the flow control device 2, the micropump is used to inje...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com