Metallic film capable of improving stability of anode of lithium ion battery and manufacturing method

A lithium ion battery and a manufacturing method technology, which are applied in the field of surface coating treatment, can solve problems such as expensive equipment, and achieve the effects of suppressing reaction, improving power characteristics and safety, and having good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

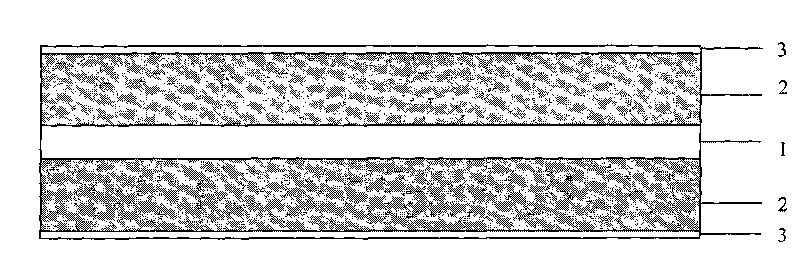

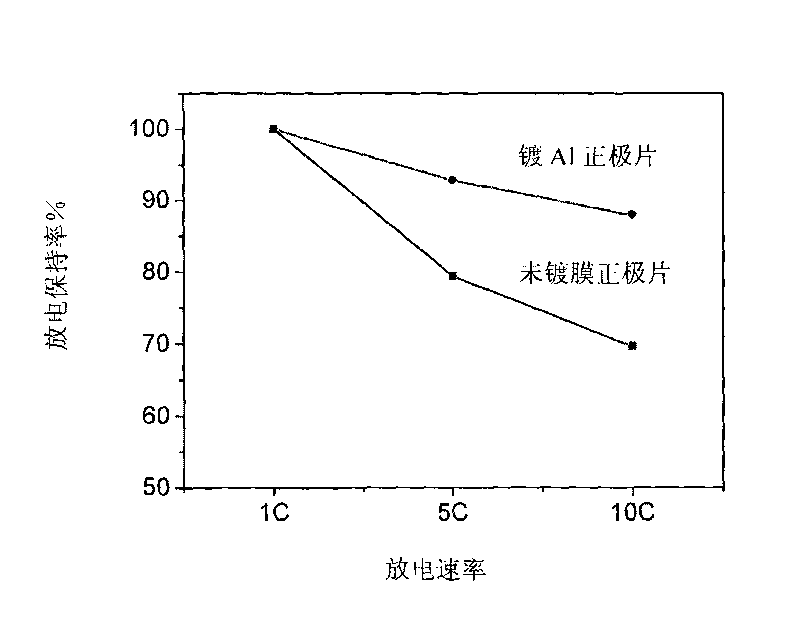

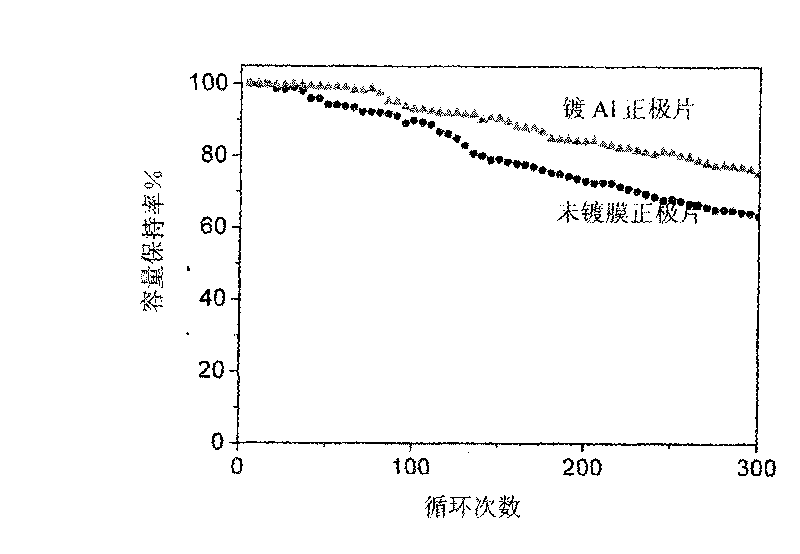

Embodiment 1

[0020] Dissolve polyvinylidene fluoride in an appropriate amount of N-methylpyrrolidone to make glue, lithium manganate and superconducting carbon black in proportion (lithium iron phosphate: superconducting carbon black: polyvinylidene fluoride=88:4 : 8wt%) was added into the glue and stirred evenly, and then coated on both sides of the aluminum foil with a film thickness of about 100um. After vacuum drying at 80°C for 12h, it was cut into pole pieces of 40×50mm. Put the cut positive electrode sheet into the sample chamber of the vacuum evaporation machine, and put the Al target into the evaporation chamber. Pump the vacuum degree of the vacuum evaporation machine to 2.0×10 -3 pa, set the evaporation distance to 15cm, the evaporation current to 380A, and the voltage to 5V, and start to coat the positive electrode. After 5 minutes of evaporation, slowly cool and take out the electrode to obtain a positive electrode with an Al-coated layer of 50nm. See figure 1 . The positive...

Embodiment 2

[0023]The positive electrode sheet made of lithium iron phosphate as the active material is coated with an Ag film with a thickness of 10nm on the surface by vacuum evaporation technology. After the positive electrode sheet is rolled, it is paired with the mesophase carbon microsphere negative electrode sheet and wound into a battery core. The battery cells are packed into shells, bottomed, roller grooved, liquid injected and sealed to obtain cylindrical lithium-ion batteries. After the battery is formed and divided, the performance test is carried out.

Embodiment 3

[0025] Using a mixture of nickel-cobalt lithium manganese oxide and lithium cobalt oxide as the active material, the positive plate is coated with a 50nm-thick Au coating on its surface and then a 50nm-thick Pd coating. After the positive electrode sheet is rolled, it is paired with the lithium titanate negative electrode sheet and wound into a cell. The battery cells are packed into shells, bottomed, roller grooved, liquid injected and sealed to obtain cylindrical lithium-ion batteries. After the battery is formed and divided, the performance test is carried out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com