Absorbable metal intramedullary nail and preparation method thereof

An intramedullary nail and metal technology, applied in the field of absorbable metal intramedullary nails and their preparation in vivo, can solve problems such as accumulation of aluminum elements, pathological changes, slow discharge, toxicity, etc., so as to reduce the stress shielding effect and promote fracture healing , beneficial to bone conduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A 94wt% Mg-6wt% Zn alloy ingot was melted, heat-treated at 400°C for 3 hours, and then hot-extruded into a rough billet at an extrusion temperature of 200°C. Then the lathe is processed into a linear intramedullary nail with a circular cross-sectional shape, and finally the surface of the linear intramedullary nail is modified by coating to obtain an absorbable metal intramedullary nail;

[0029] The absorbable metal intramedullary nail prepared in this example has a diameter of 5 mm and a length of 30 mm, and a hydroxyapatite coating is prepared by a thermal spraying method. The three-point bending strength is 600MPa, the tensile strength is 300MPa, and the elastic modulus is 41GPa.

Embodiment 2

[0031] Melting 99.3wt% Mg-0.7wt% Ca alloy ingot, heat treatment at 500°C for 4 hours, then hot extruding into rough bar billets, extrusion temperature is 300°C, machined into linear pith with closed clover shape in section Intramedullary nail, and then the surface of the linear intramedullary nail is modified by coating to obtain an absorbable metal intramedullary nail;

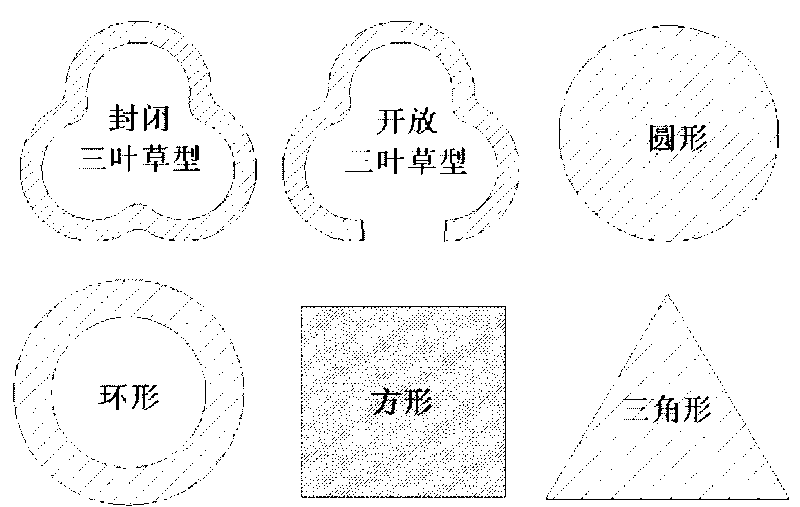

[0032] The cross-sectional shape of the absorbable metal intramedullary nail prepared in this example is as follows: figure 1 shown in . The length of the nail is 100mm, the tricalcium phosphate coating is prepared by laser cladding method, soaked in 1 liter of simulated body fluid in vitro, after a month of degradation, the weight loss rate is 30%, and X-ray diffraction (XRD) shows that there are hydroxyapatite on the surface Osteoid Ca-P salt deposition.

Embodiment 3

[0034] Melting 99wt% Mg-1wt% Mn ingot, heat treatment at 600°C for 5 hours, hot extruding into rods, extrusion temperature at 400°C, machining into linear intramedullary nail with square cross section, and then The surface is modified by coating to obtain absorbable metal intramedullary nails;

[0035] The absorbable metal intramedullary nail prepared in this example is as follows: figure 2 Shown, and the magnesium fluoride coating was prepared by hydrothermal treatment. The three-point bending strength is 600MPa. The weight loss rate is 15% after immersion in normal saline in vitro for 1 month, and the three-point bending strength is found to be above 400MPa. It is proved that certain mechanical properties can be maintained during the degradation process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com