Electronic control unit (ECU) of electromagnetic-type high-pressure common-rail injection system for vehicle diesel engine

An electronic control unit, high-pressure common rail technology, applied in fuel injection control, electrical control, engine control and other directions, can solve the problems of the late start of diesel electronic control technology research, restricting the rapid development of diesel engine technology, and low investment, etc. Interference ability, solving heating problems, reducing the effect of volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

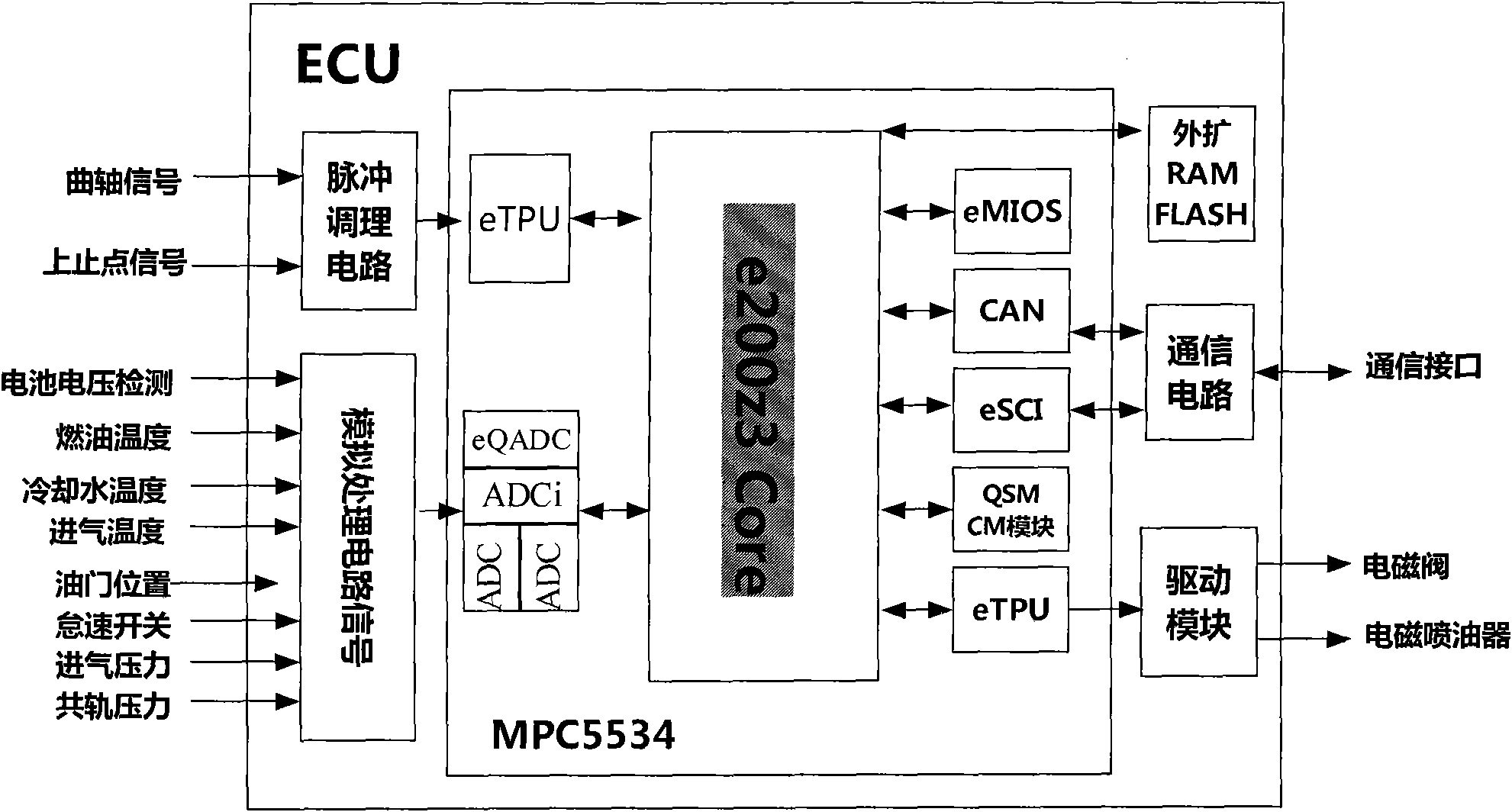

[0012] The hardware structure of the electronic control unit is attached figure 1 shown. The system hardware consists of four parts: input module, microcontroller module, output module and communication module. The input module includes digital input and analog input, and is composed of signal processing circuits; the microcontroller module is composed of MPC5534 as the core single-chip microcomputer and peripheral circuits; the output module is the driving circuit of high-pressure common rail pressure control valve and fuel injector solenoid valve ; The communication module mainly includes FlexCAN and eSCI serial communication interface circuits.

[0013] The input module includes a pulse width conditioning circuit and an analog input conditioning circuit. The input part is mainly a signal processing circuit, which converts the output signal of the peripheral sensor circuit into a signal that the core processor can recognize. In the diesel engine high-pressure common rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com