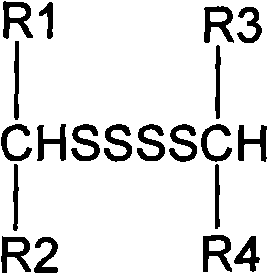

Method for preparing tetra-sulfenyl polyhydric mercaptan and method for preparing polyurethane-based resin lens by using tetra-sulfenyl polyhydric mercaptan

A technology based on ethyl and mercapto groups, applied in the field of polyurethane-based resins, can solve the problems of low refractive index and achieve the effects of strong weather resistance, good machinability, and good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In a 500mL four-necked flask equipped with an electric stirrer, reflux condenser, thermometer and dropping funnel, add 50mL petroleum ether and 20mL 2-mercaptoethanol, cool to 0℃ with an ice water bath, and add 10mL one by one within 1 hour. A mixed solution of sulfur chloride and 50 mL of petroleum ether was then stirred for 10 hours to obtain a crude product. The obtained product was extracted and purified three times with 100 ml of water, and the organic phase was separated and dried with anhydrous calcium chloride. The petroleum ether was distilled off under reduced pressure, and the fraction at 34-38°C was collected to obtain about 25 g of colorless viscous liquid bis(22 hydroxy) ethyl tetrasulfide. Subsequently, 30.1 g of 36% hydrochloric acid and 19 g of thiourea were added to bis(22 hydroxy) ethyl tetrasulfide, stirred and heated to 110° C. for 9 hours. The mixture was cooled to room temperature, 50 ml of toluene was added thereto, and then 31 g of 25% ammonia w...

Embodiment 2

[0024] In a 500mL four-necked flask equipped with an electric stirrer, reflux condenser, thermometer and dropping funnel, add 50mL petroleum ether and 20mL 2-mercaptoglycol, cool to 0℃ with an ice water bath, and add dropwise within 1 hour A mixed solution of 10 mL of sulfur monochloride and 50 mL of petroleum ether was then stirred for 10 hours to obtain a crude product. The obtained product was extracted and purified three times with 100 ml of water, and the organic phase was separated and dried with anhydrous calcium chloride. The petroleum ether was distilled off under reduced pressure, and the fraction at 34-38°C was collected to obtain about 30 g of colorless viscous liquid bis(2222 hydroxy) ethyl tetrasulfide. Subsequently, 60.2 g of 36% hydrochloric acid and 38 g of thiourea were added to bis(2222 hydroxy) ethyl tetrasulfide, and the mixture was stirred and heated to 110° C. for 9 hours. The mixture was cooled to room temperature, 50 ml of toluene was added thereto, an...

Embodiment 3

[0027] In a 500mL four-necked flask equipped with an electric stirrer, reflux condenser, thermometer and dropping funnel, add 50mL petroleum ether and 20mL 2-mercaptopropanol, cool to 0℃ with an ice water bath, and finish the dripping within 1 hour. A mixed solution of 10 mL of sulfur monochloride and 50 mL of petroleum ether was then stirred for 10 hours to obtain a crude product. The obtained product was extracted and purified three times with 100 ml of water, and the organic phase was separated and dried with anhydrous calcium chloride. The petroleum ether was distilled off under reduced pressure, and the fraction at 34-38°C was collected to obtain about 25 g of colorless viscous liquid bis(22 hydroxy) ethyl tetrasulfide. Subsequently, 30.1 g of 36% hydrochloric acid and 19 g of thiourea were added to the bis(22 hydroxy) propyl tetrasulfide, stirred and heated to 110° C. for 9 hours. The mixture was cooled to room temperature, 50 ml of toluene was added thereto, and then 31...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com