Novel aluminium packaging can and production method thereof

A production method and technology for packaging cans, which are applied in the field of new aluminum packaging cans, can solve the problems of frequent use of the valve nozzle at the material outlet of the can, material waste, and high sealing performance of the valve nozzle, and achieve convenient eating speed, reduce production costs, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A further detailed description will be made below in conjunction with the accompanying drawings and embodiments of the present invention:

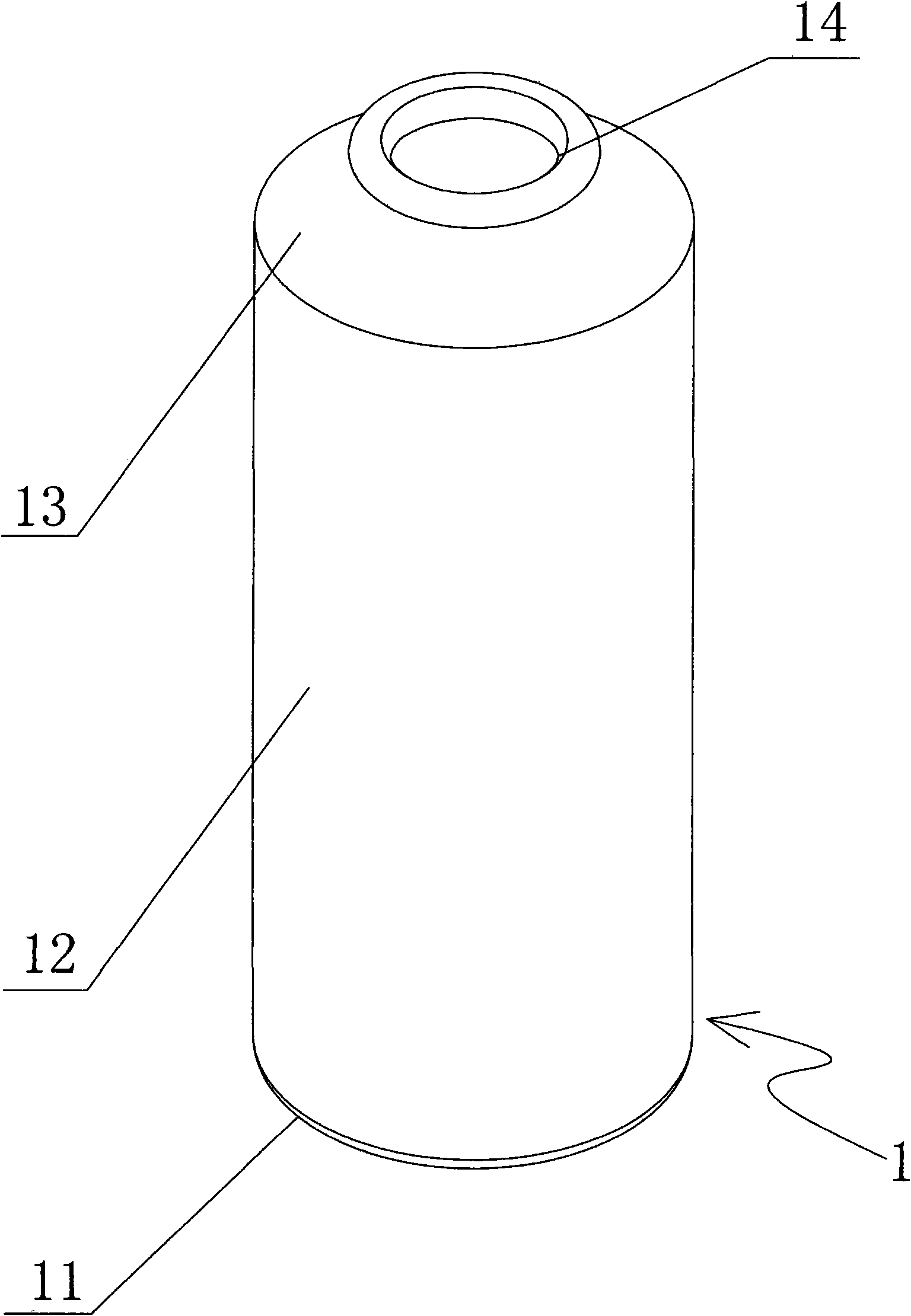

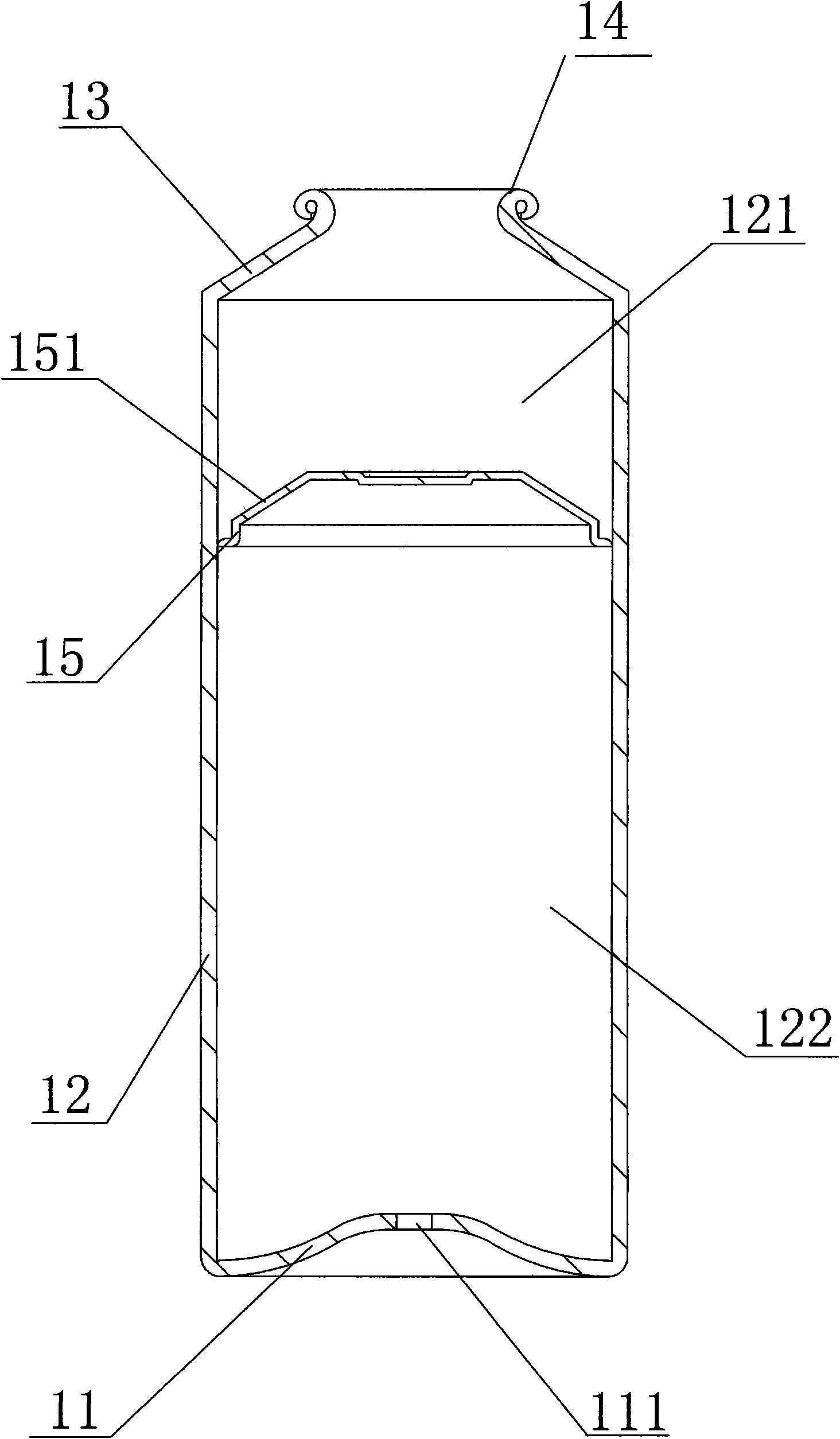

[0026] As shown in the figure, the new aluminum packaging can includes an aluminum can body 1. The aluminum can body 1 is made by adding an appropriate amount of lubricant to a certain amount of aluminum sheet and fully stirring it evenly before being extruded by a stamping machine with a corresponding mold. , trimmed to length, shrunk shoulders and turned over by mechanical action. The aluminum tank body 1 is sprayed with a protective film (not shown) for anti-corrosion, so that the shelf life of the aluminum tank body 1 is longer after storing the liquid agent; the aluminum tank body 1 outer surface can also be coated with a mimeograph layer ( Not shown in the figure), so that it is convenient to mimeograph patterns and characters on the primer, mimeograph patterns and characters can be carried out according to customer requiremen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com