Roll of water-soluble polyvinyl alcohol film and method of storing the same

A polyvinyl alcohol film, polyvinyl alcohol-based technology, applied to flexible coverings, other household appliances, applications, etc., can solve the problems of film deformation, lower yield, and inability to completely prevent moisture absorption, etc., to achieve suppression of deformation or wrinkle Crease generation and effect of reducing residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

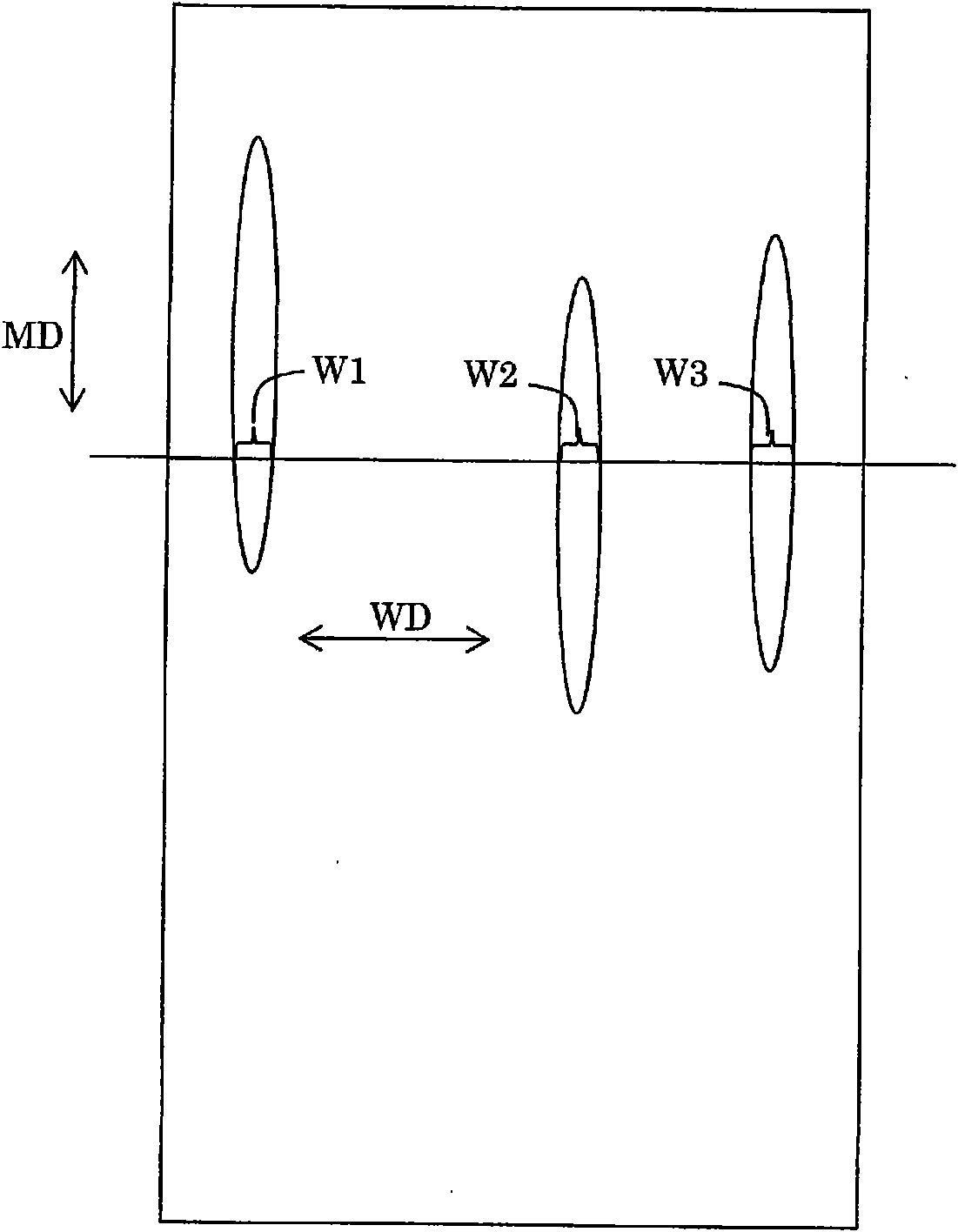

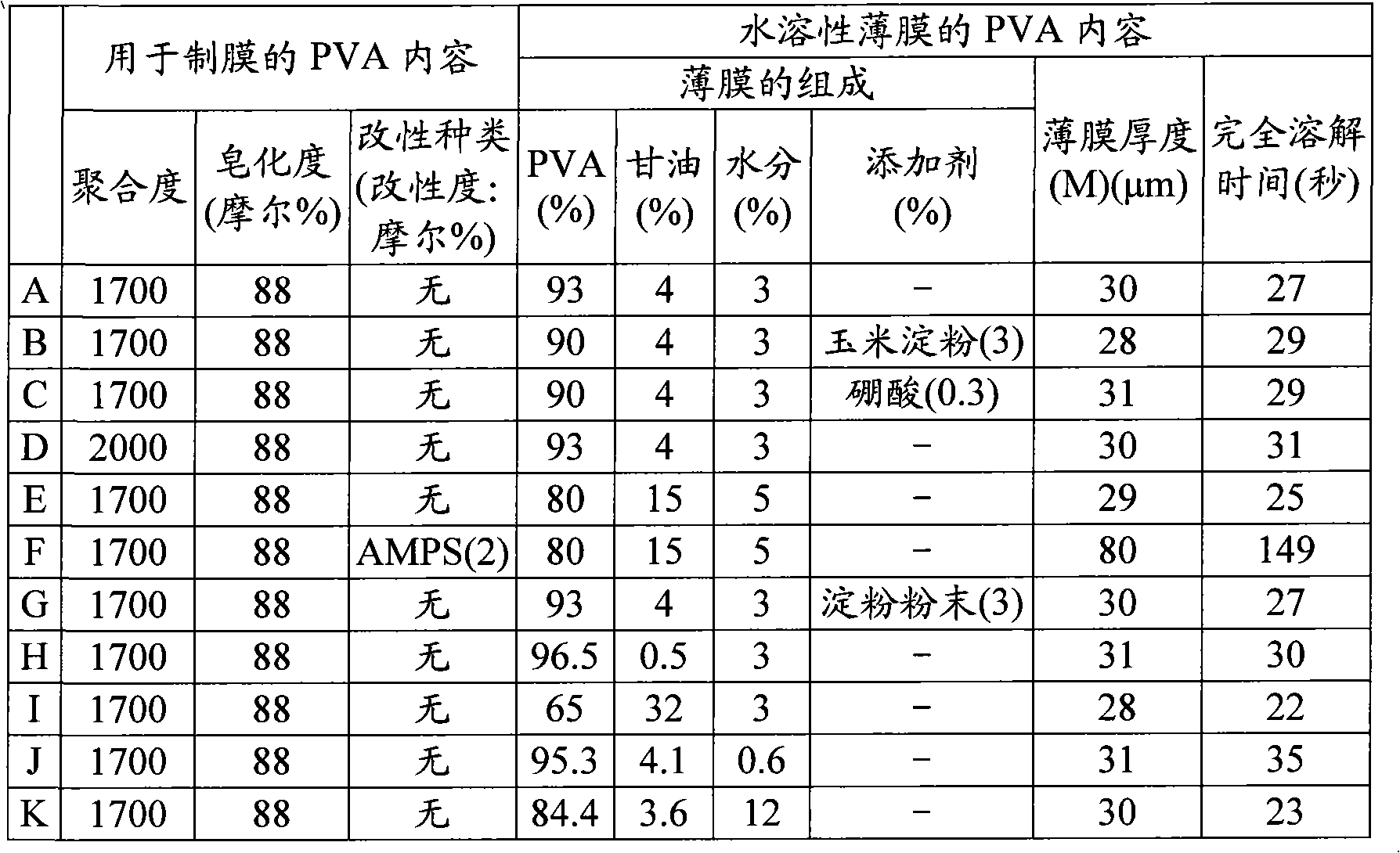

[0128] By containing 88 mol % of saponification degree, PVA 15 weight parts of polymerization degree 1700, glycerin 0.65 weight part PVA concentration is the aqueous solution of 15 weight % casting on the conveyer belt, while blowing the hot air of 120 ℃ on the belt, dry 5 After 10 minutes, the film was obtained, and then, the film was passed on a metal roller that had been satin-finished (150 mesh sandblasting), and after embossing was performed on one side, the two ends of the film were cut off by a blade to obtain The film width (W) is 500 mm, the film thickness (M) is 30 μm, the roughness of the embossed surface is 0.3 μm, and the roughness of the non-embossed surface is 0.15 μm. Velocity 0.5m / sec, cut-off value λc=0.8 for measurement) PVA film {length (L) 1000m (no remainder)}, through initial winding tension 15kgf, winding speed 40m / min, contact pressure 3kgf / m 2, Taper 75%, wind this PVA film on a cylindrical paper tube [outer diameter (D) of the paper tube (D) 88.2mm, ...

Embodiment 2

[0133] In Example 1, except that the winding tension when the PVA film is wound on the paper tube is set to 10kgf, in the same manner as in Example 1, a roll of water-soluble PVA film {roll section of the roll Diameter (H) 228mm}. In the same manner as in Example 1, the obtained rolls were packaged into double coils using a low-density polyethylene film, and then stored in a warehouse for half a year as in Example 1. After storage, the water-soluble PVA film obtained from the roll taken out from the package was unfolded. Table 1 shows the results of determining the state of deformation and wrinkles of the water-soluble PVA film at this time in the same manner as in Example 1. In addition, when the take-up tension is converted into the take-up tension of the film per 1 m film width, the value is 20 kgf / lm width.

Embodiment 3

[0135] In Example 1, except that the take-up speed when the PVA film is wound on the paper tube is set to 50m / min, in the same manner as in Example 1, a roll of water-soluble PVA film {roll Section diameter (H) 219mm}. In the same manner as in Example 1, the obtained rolls were packaged into double coils using a low-density polyethylene film, and further stored in a warehouse the same as in Example 1 for half a year. After storage, the water-soluble PVA film obtained from the roll taken out from the package was unfolded. Table 1 shows the results of determining the state of deformation and wrinkles of the water-soluble PVA film at this time in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com