Evaporator for mobile anhydrous ammonia production, and method for manufacturing such an evaporator

A technology of evaporation device and evaporator, which is applied in evaporation device, boiling device, exhaust device, etc., can solve the problems of blockage of evaporator unit and achieve the effect of effective evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

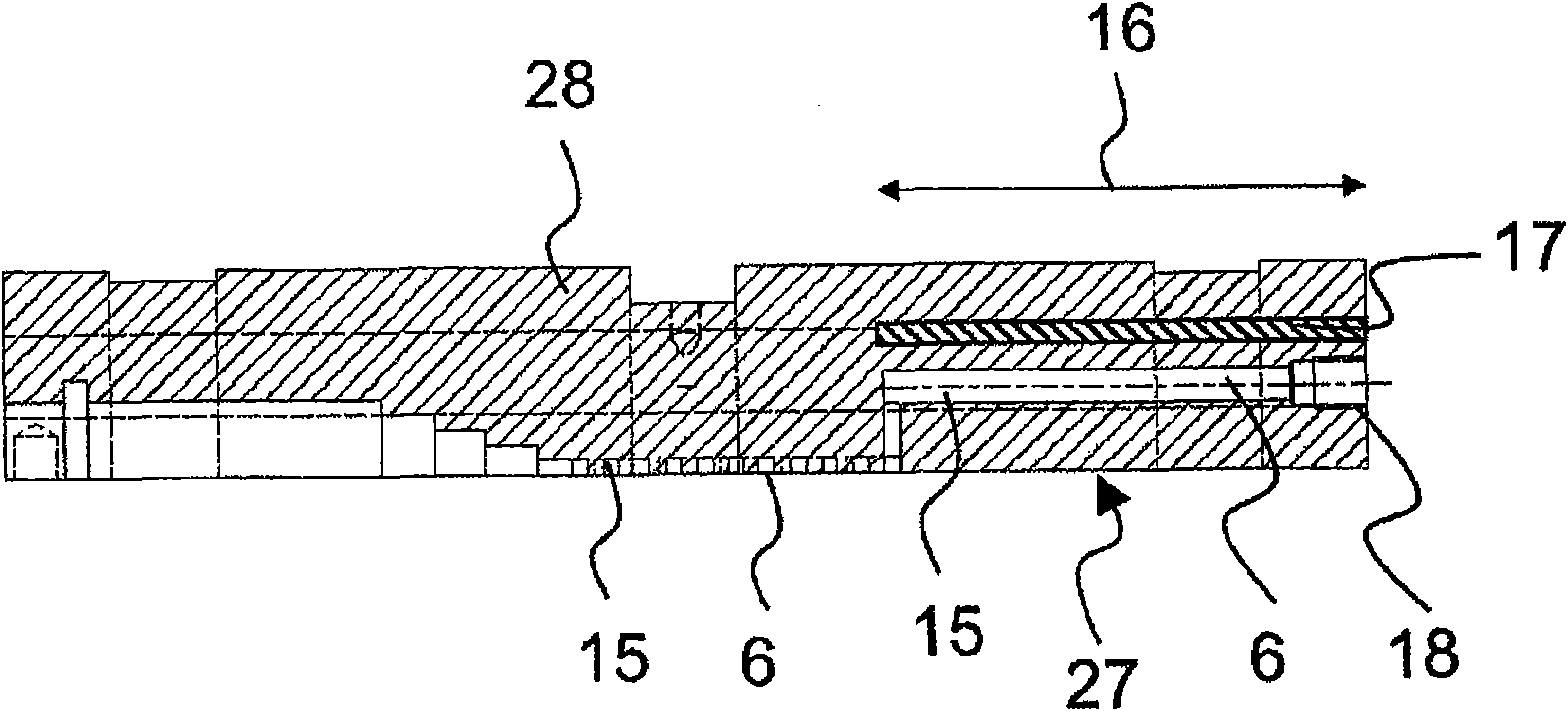

[0092] figure 1 The structure of a particularly preferred variant embodiment of the evaporation device 1 is schematically shown, the main body 2 used here being shown "open" for the sake of clarity. according to figure 1 , the main body 2 comprises a first part 28 and a second part 29 which are connected together by their common interface 27 in order to make the evaporation device 1 work. In this two-piece construction of the main body 2 , the first part 28 and the second part 29 each have two receptacles 30 , each for receiving a heating element 5 positioned at the longitudinal axis 39 of the main body 2 . extends across the entire length in the direction of . Also shown in the right-hand area are electrical connections for a heating element formed as a PTC resistor (PTC: positive temperature coefficient or so-called Kaltleiter). Starting from the interface 27 , the upper region of the reactor chamber 21 is formed in the second part 29 . Only the outlet portion 19 of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com