A method for forming a vacuum pump intake casing

A molding method and air intake cover technology, applied to casting molding equipment, molds, cores, etc., can solve the problems of increasing the production cost and efficiency of the intake cover, poor cooling effect of the intake cover, and limited heat dissipation area of the cooling plate and other issues, to achieve the effect of convenient implementation, low cost, and prevention of melt-through

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

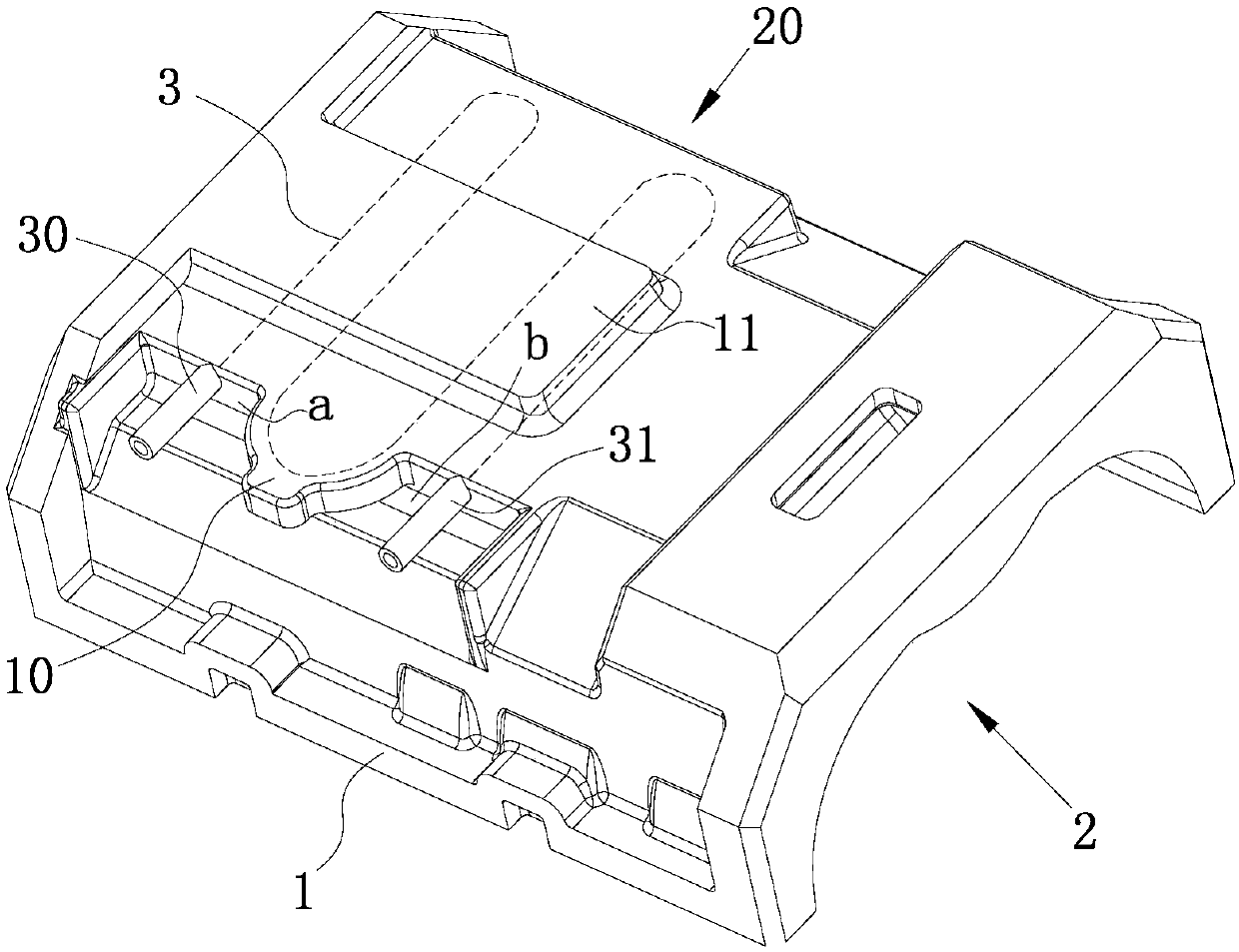

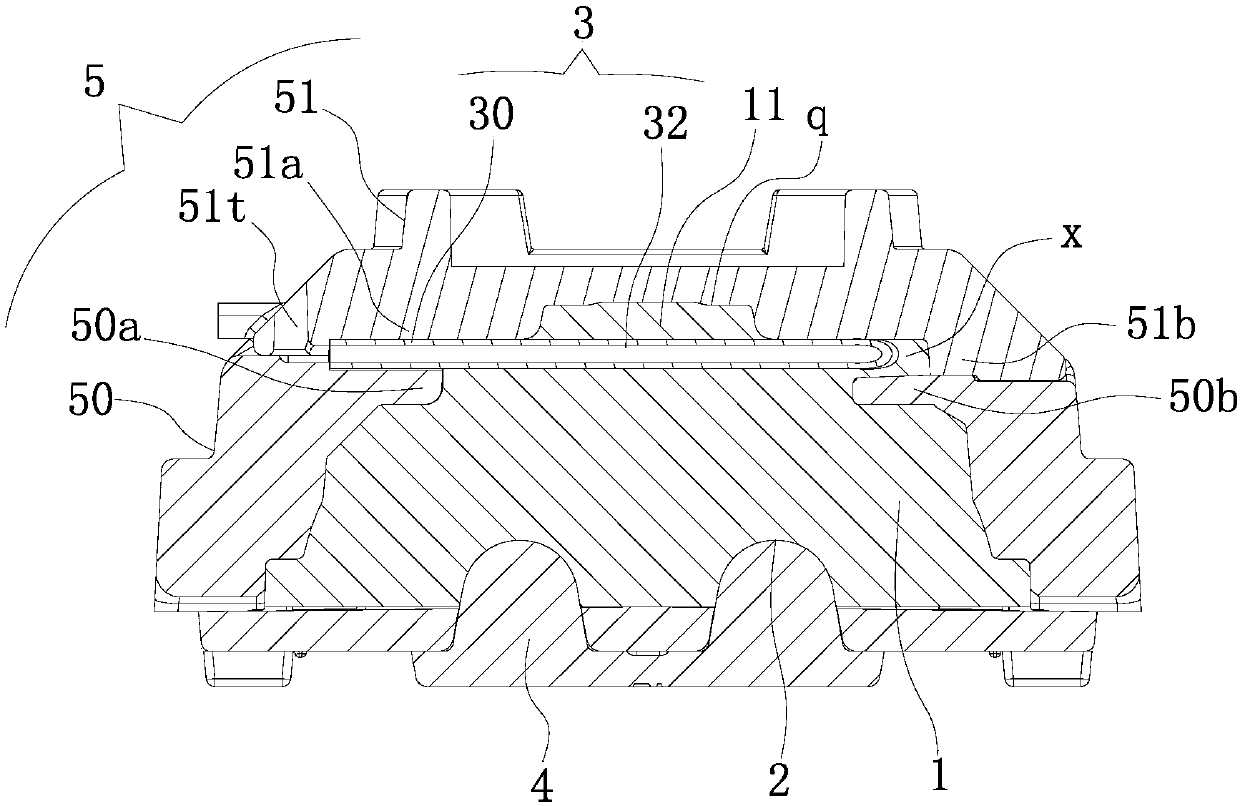

[0030] Such as figure 1 with figure 2 As shown, the intake casing of the vacuum pump of this embodiment includes a casing 1, a cavity on the casing 1 forming a space for the rotor to rotate, a condensing coil 3 arranged inside the casing 1, wherein the casing 1 It is formed by integral casting and fusion with the condensing coil 3. The condensing coil 3 is horizontally arranged above the cavity 2 and the formed cooling area covers the space of the cavity occupied by the rotor.

[0031] In this example, the molding die of the air intake cover includes a lower sand core 4 that forms the cavity 2 and an upper sand core 5 that forms the outer contour of the shell 1. The upper sand core 5 includes the lower sand core 4 which is attached to and used The first sand core 50 on which the condensing coil 3 is erected, and the second sand core 51 pressed on the first sand core 50 and the condensing coil 3.

[0032] The condensing coil 3 includes a tube body 32 fused in the shell 1, a medium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com