Apparatus for detecting and measuring cylindrical surfaces on fireproof ceramic components in metallurigal applications

A technology of ceramics and components, which is applied in the field of devices with columnar surfaces, can solve problems such as inaccurate results, and achieve the effect of preventing melt-through

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

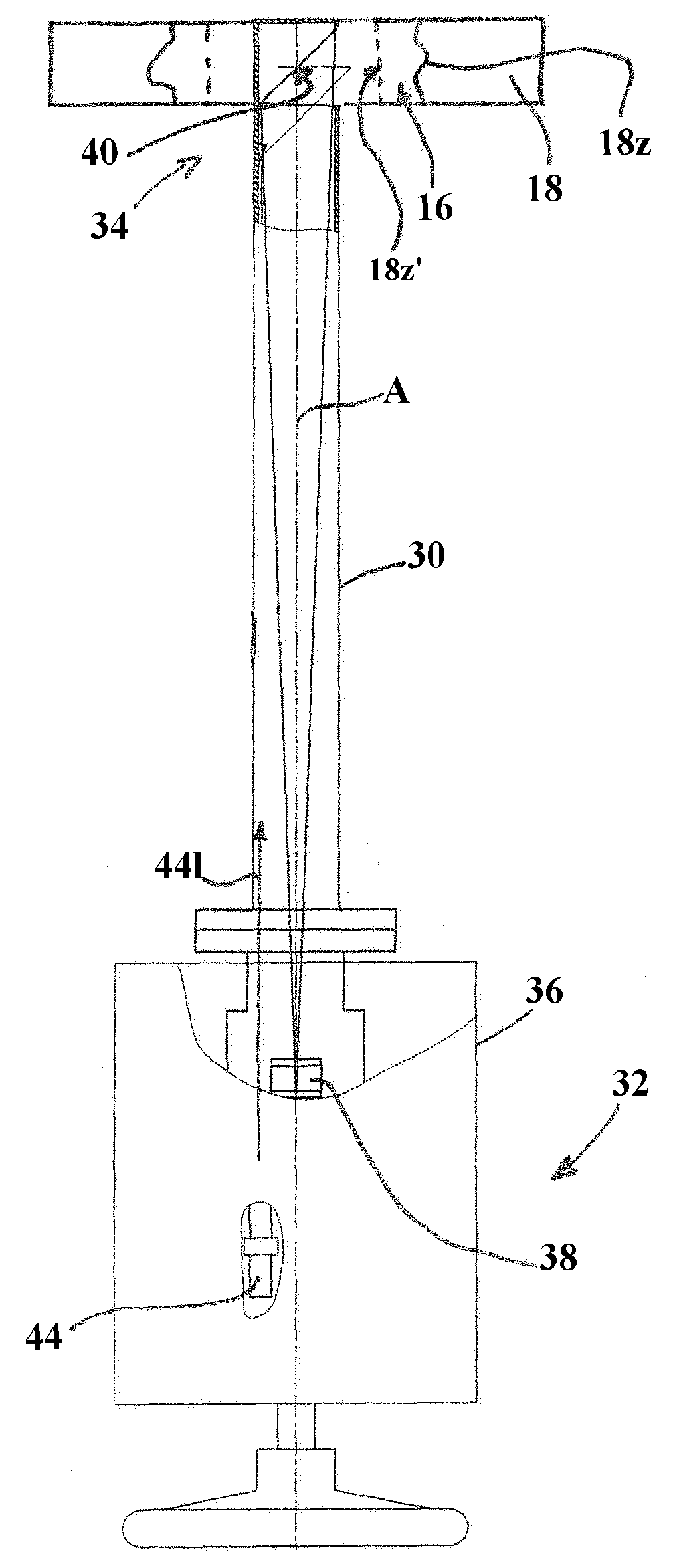

[0039] The figure shows a cylindrical measuring tube 30 with a first end 32 (the so-called "cold end") and a second end 34 (the so-called "hot end").

[0040] The measuring tube 30 widens at a first end 32 and accommodates in this section a camera 38 , here a single-lens reflex camera.

[0041] Camera 38 is aligned in the direction of reflective surface 40 , which is located within second end 34 of measuring tube 30 and extends here at an angle of 45° to longitudinal center axis A of measuring tube 30 .

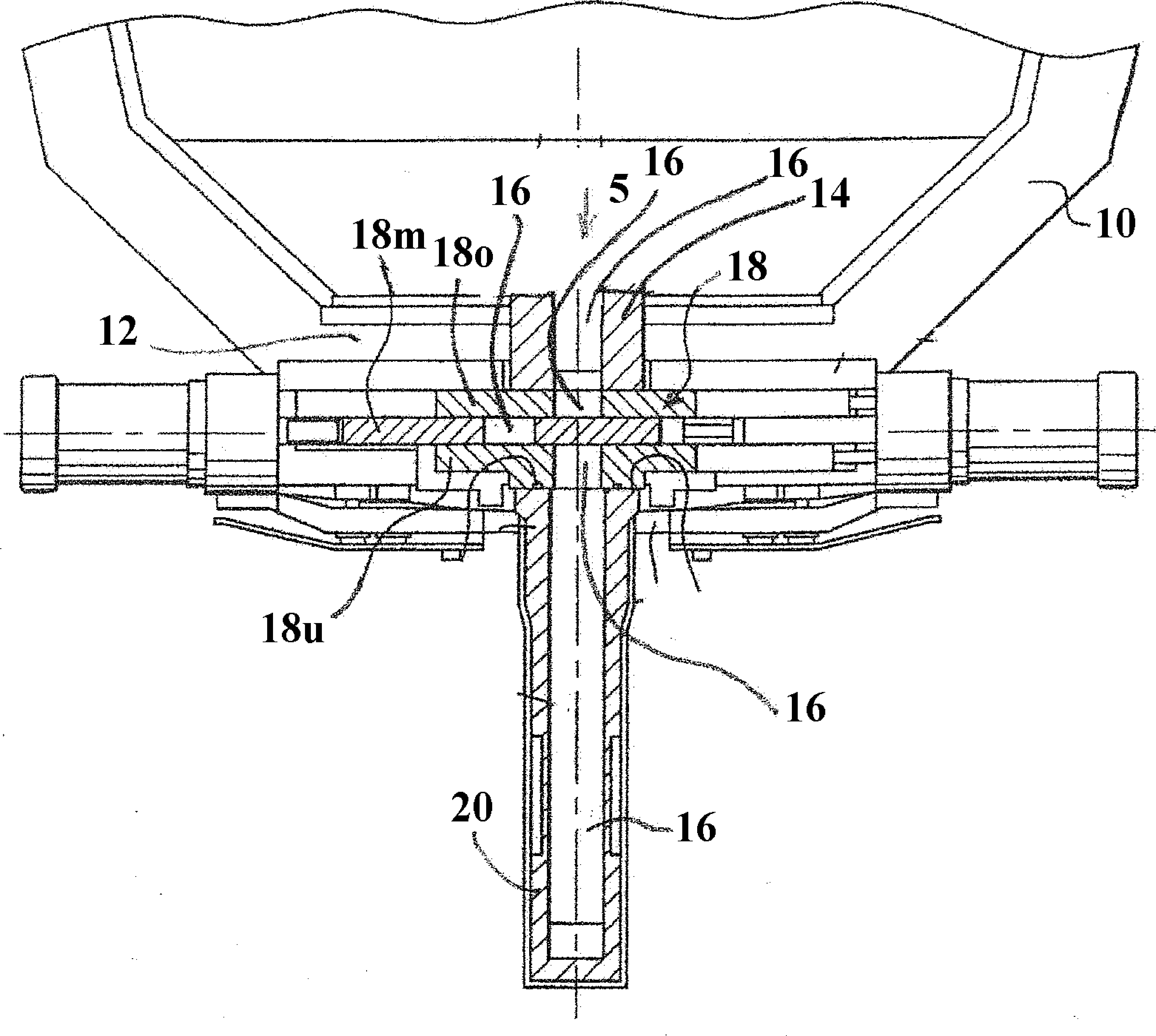

[0042]The measuring tube 30 has corresponding openings 42 in adjacent wall sections, so that parts of the cylindrical surface 18 o of the slide 18 can be detected by means of the camera 38 via the reflective surface 40 .

[0043] exist figure 2 The course of the cylindrical surface of the new slide is shown in dashed lines (18z'), while the solid line (18z) shows exemplary states of wear which are to be detected and evaluated by means of the device according to the inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com