Photochemical chemical oxygen demand (COD) sensor and method of measuring same

A sensor and photochemical technology, applied in the field of sensors, can solve problems such as failure to achieve real-time measurement, and achieve the effects of fast measurement speed, good real-time performance and extended life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

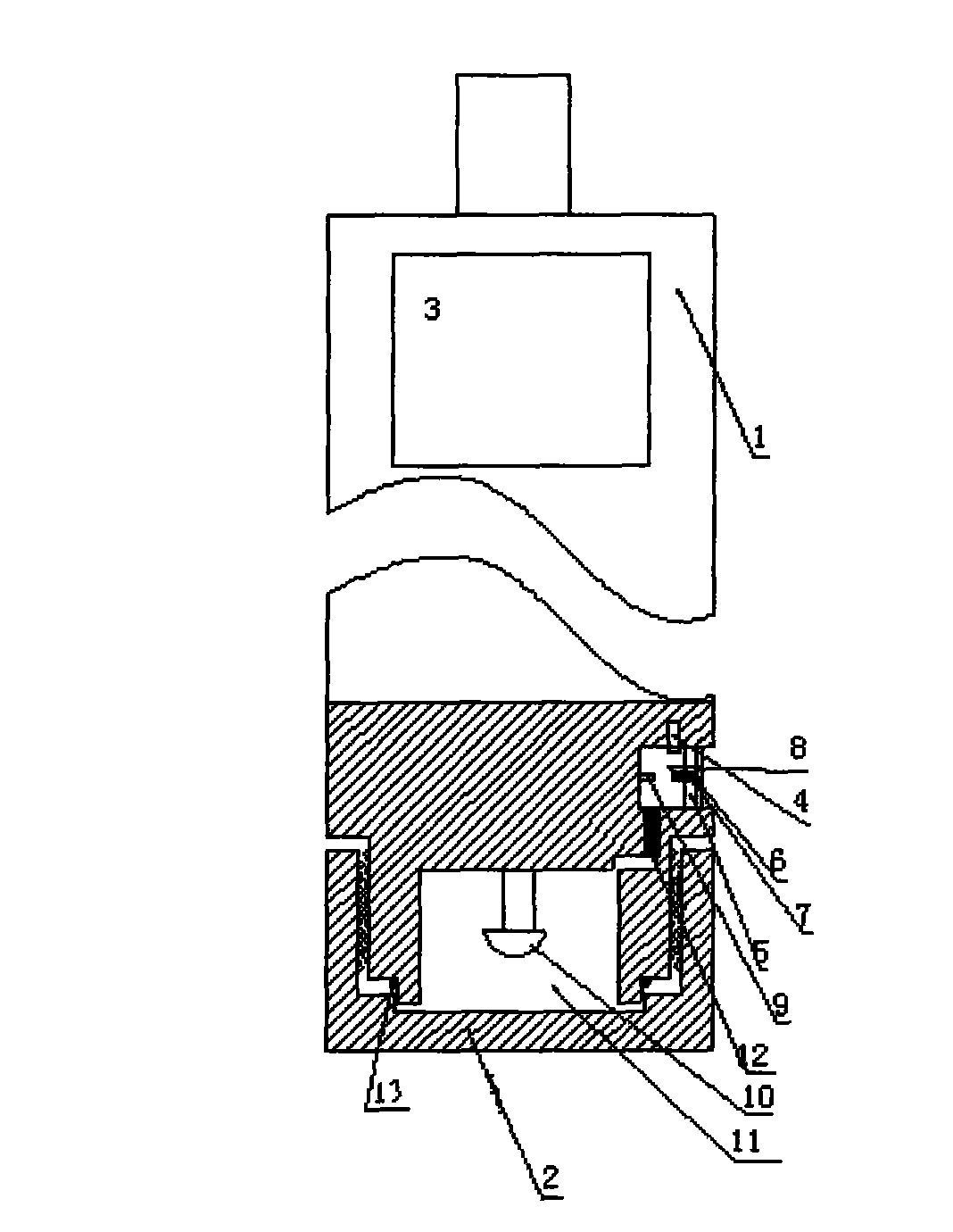

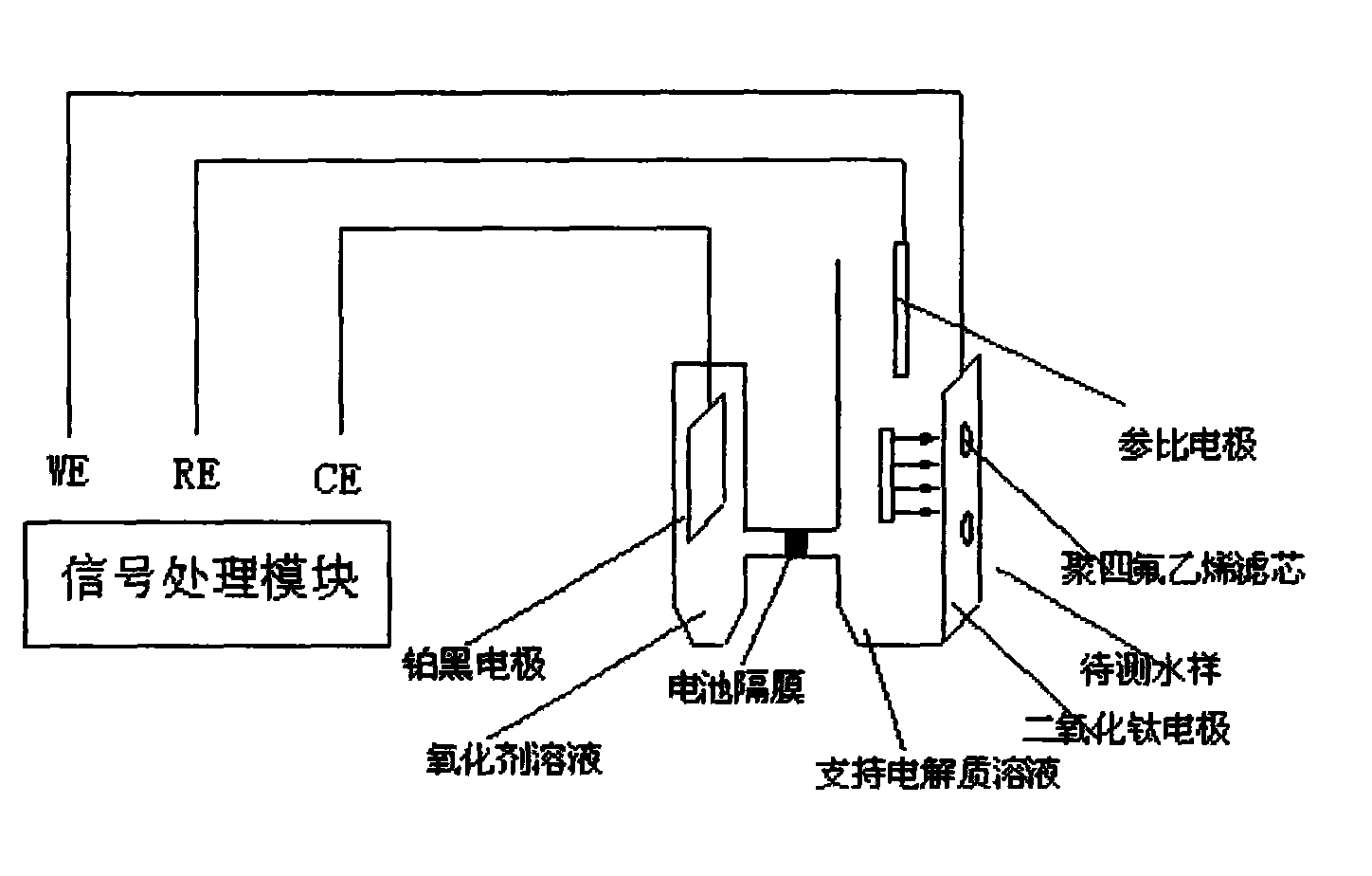

[0026] see figure 1 , figure 2A photochemical COD sensor, including electrode body 1, electrode cover 2, central processing circuit board 3, silver / silver chloride reference electrode 4, nano-titanium dioxide working electrode 5, filter hole cleaning brush 6, electrode glass substrate polytetrafluoroethylene Ethylene filter element 7, supporting electrolyte chamber 8, ultraviolet light-emitting diode 9, counter electrode 10, counter electrode electrolyte chamber 11, battery diaphragm polytetrafluoroethylene filter element 12, O-ring 13. The electrode casing and the electrode body are both processed by turning polytetrafluoroethylene rods.

[0027] The reference electrode was a silver / silver chloride electrode. Production method: Plating a si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com