Aluminum rich bulk amorphous alloy and preparation method thereof

An amorphous alloy and bulk technology, applied in the field of alloys, can solve the problems of increased amorphous cost, poor aluminum-based amorphous formation ability, low aluminum content, etc., and achieves the effect of high strength and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1, Al 40 La 35 Y 10 Ni 15 Preparation of Bulk Amorphous Alloy

[0037] Use Al, La, Y and Ni with a purity of more than 99.5% to prepare bulk amorphous alloys. First, after the four components are prepared in a molar ratio of 40:35:10:15, the argon adsorbed on titanium The ingot is repeatedly smelted in an electric arc furnace with an atmosphere, mixed evenly, and the master alloy ingot of Al-La-Y-Ni quaternary alloy is obtained after cooling; Re-melting, using the suction casting device in the electric arc furnace, sucking the master alloy melt into the water-cooled copper mold to obtain the aluminum-rich bulk amorphous alloy of the present invention, whose composition is Al 40 La 35 Y 10 Ni 15 , 1mm in diameter.

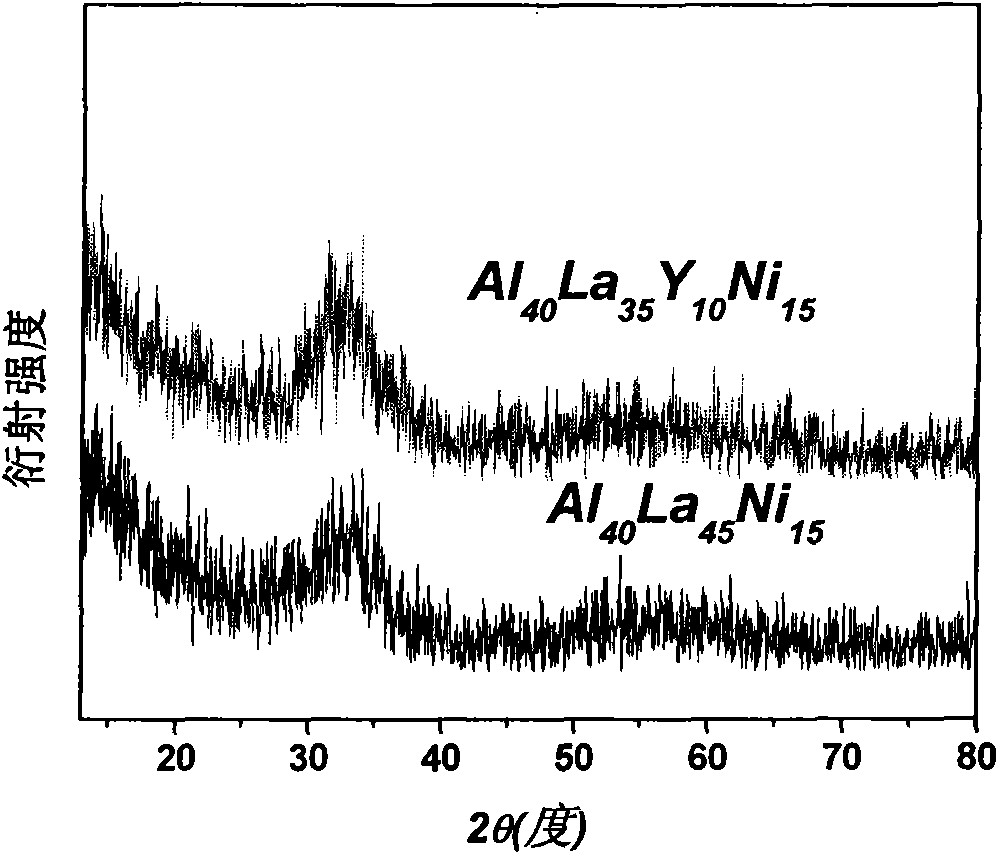

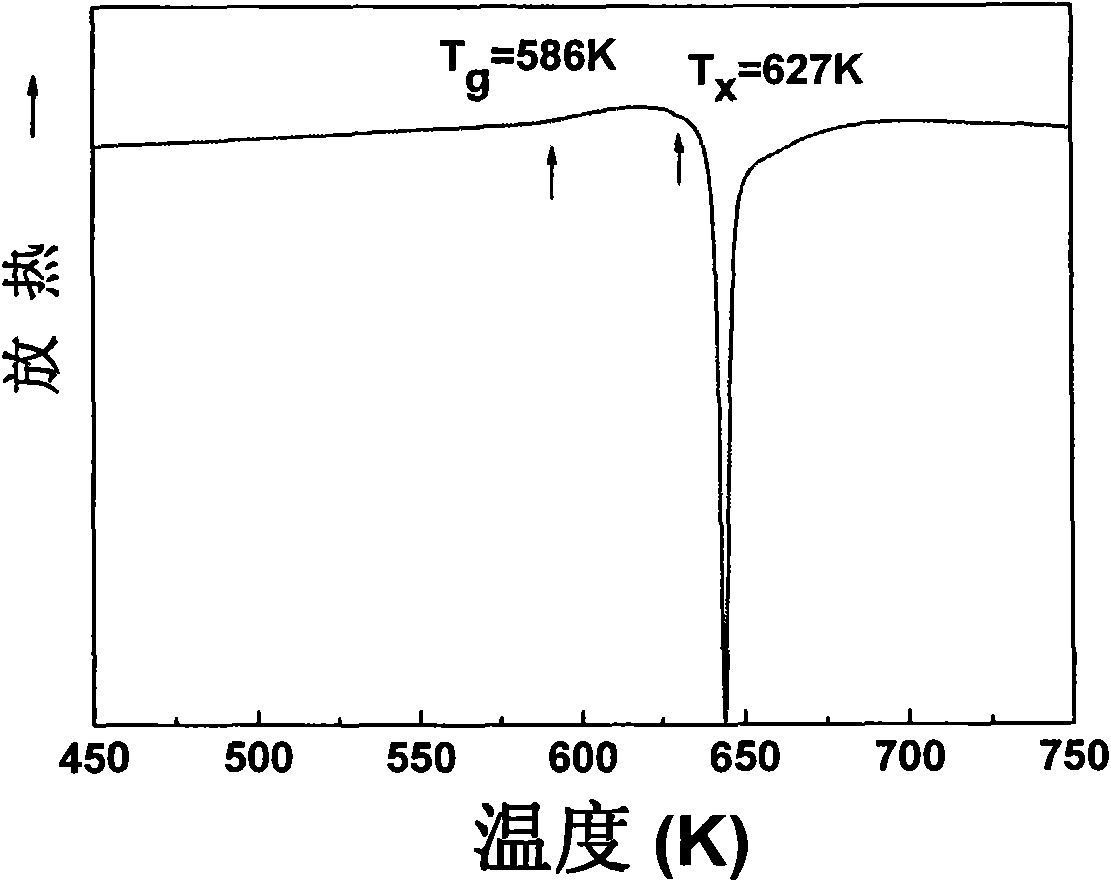

[0038] Such as figure 1 X-ray diffraction (XRD) shown proves that the alloy is completely amorphous. Such as figure 2 The thermal analysis (DSC) diagram shown, its glass transition temperature (T g ), crystallization onset temperature ...

Embodiment 2~29

[0040]Various ratios of aluminum-rich bulk amorphous alloys were prepared according to the method of Example 1, and their compositions and thermophysical parameters are listed in Table 1.

[0041] Table 1. Composition and thermophysical parameters of bulk amorphous alloys with high aluminum content

[0042] Reality

apply

example

T g

(K)

T x

(K)

T m

(K)

Tl

(K)

ΔTg

(K)

T rg

gamma

1

Al 40 La 35 Y 10 Ni 15

586

627

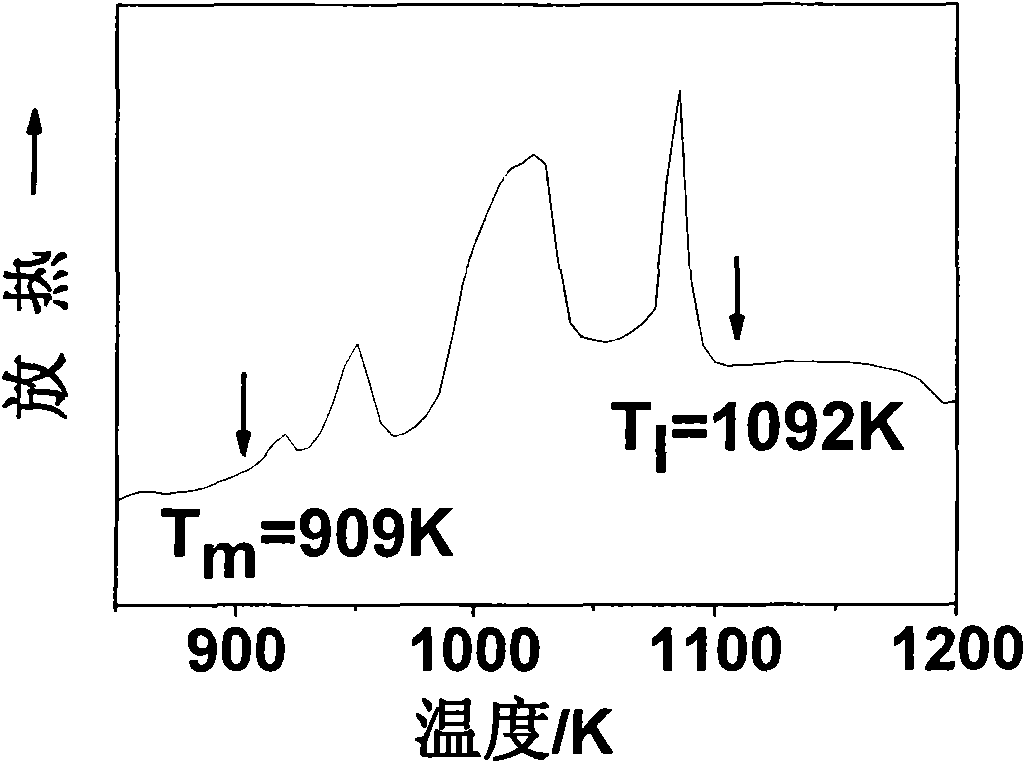

909

1092

41

0.536

0.374

2

Al 40 La 35 Y 10 Ni 10 co 5

579

619

763

1088

40

0.532

0.371

3

al 40 La 45 Ni 15

540

600

782

1097

60

0.492

0.367

4

Al 35 La 30 Ce 20 Ni 15

542

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com