Processing technology for manufacturing board by utilizing crop straws

A technology for crop straw and processing technology, which is applied in the direction of wood processing appliances, manufacturing tools, pretreatment of molding materials, etc. Yield and processing efficiency, the effect of overcoming the moisture content problem and improving the moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

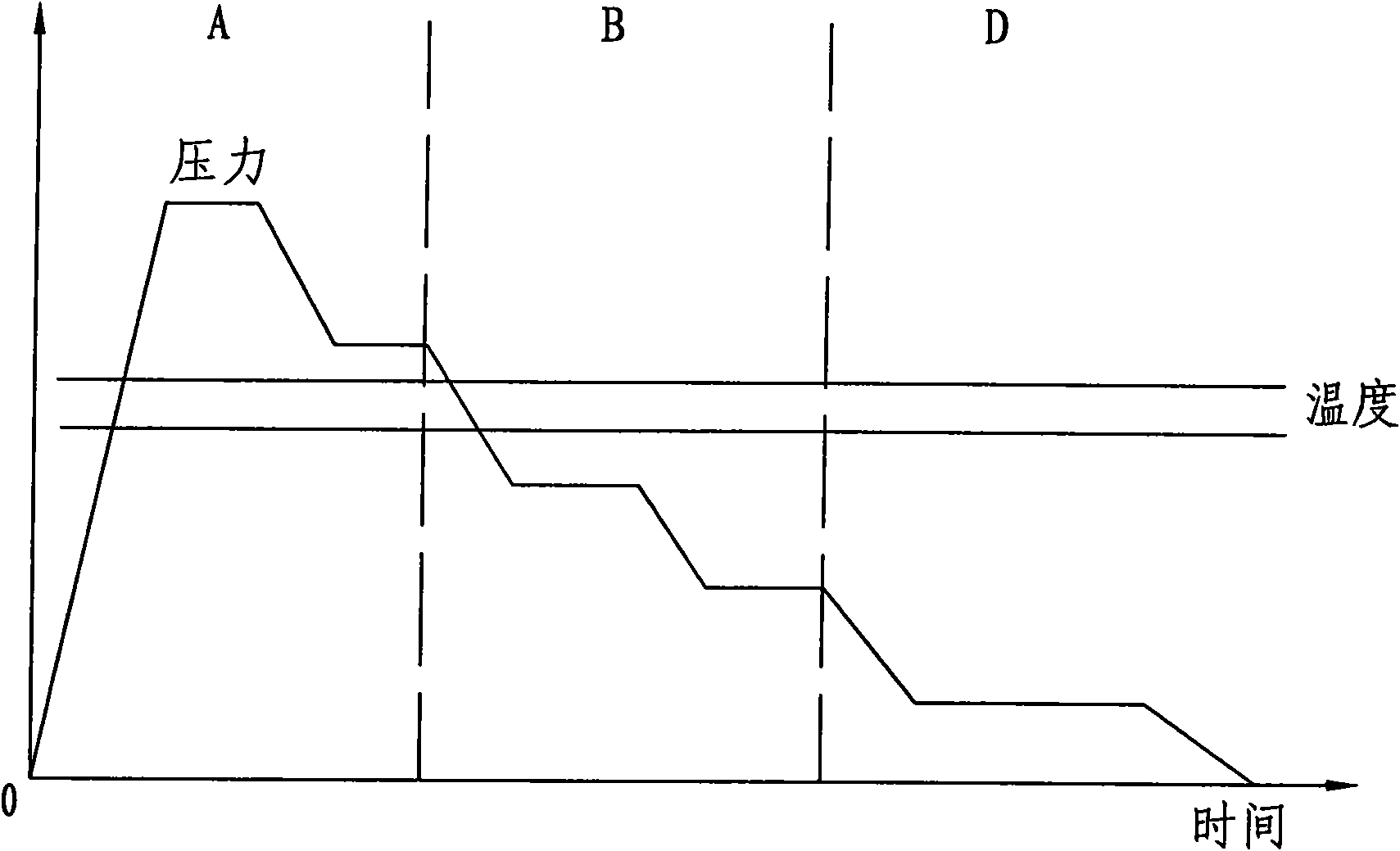

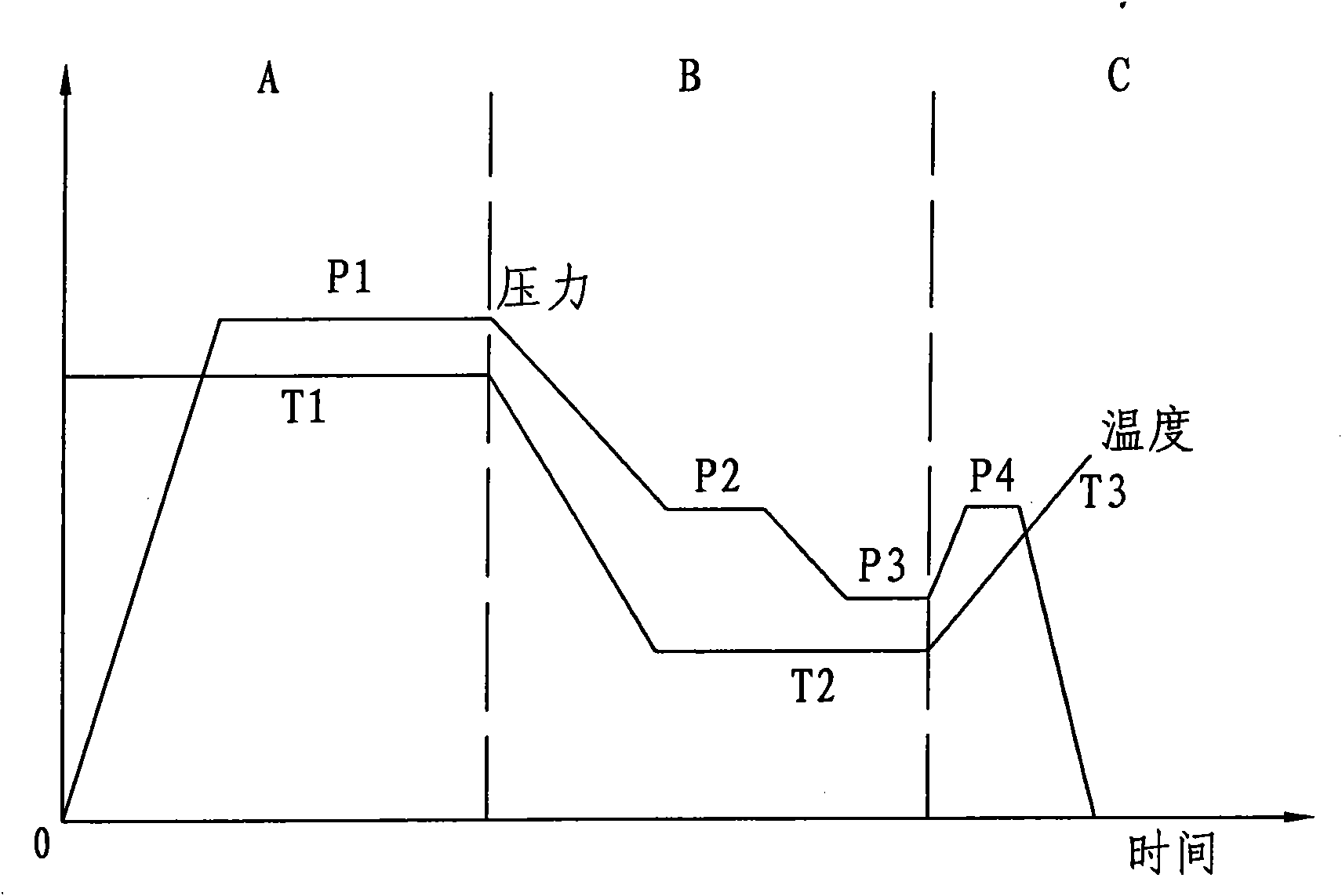

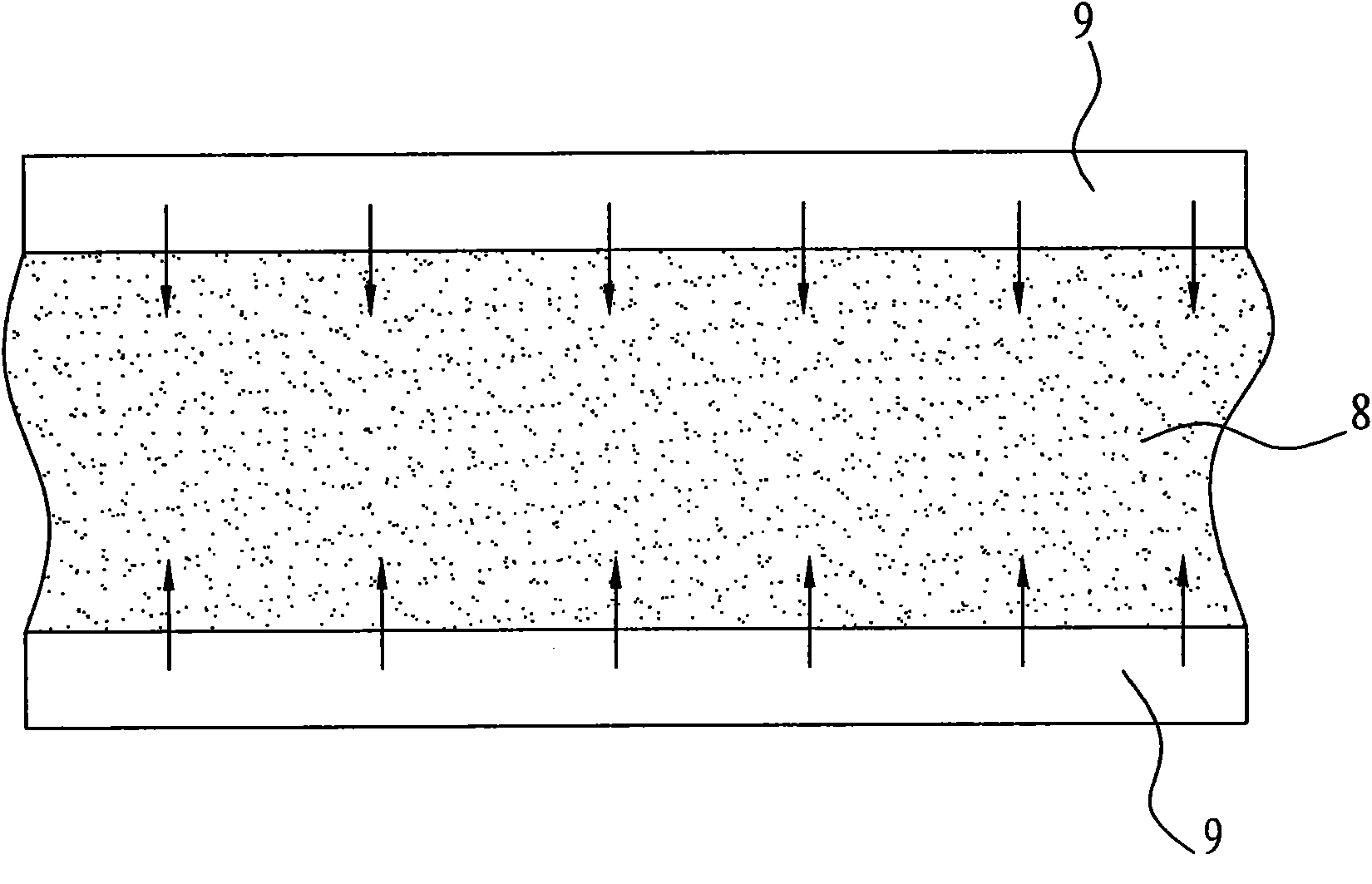

Method used

Image

Examples

Embodiment 1

[0055] (1) Material preparation:

[0056] Wheat straw (origin: Chuzhou, Anhui) is pulverized by a hammer mill. The diameters of the double screens of the pulverizer are 6mm and 6mm respectively. The moisture content of the crushed straw material is 12.5%. In a blender, atomize isocyanate (PMDI) adhesive and mix evenly with crushed wheat straw. The adhesive used was Huntsman Suprasec 5005, and the sizing amount was 3.5% of the dry weight of the crushed wheat straw.

[0057] (2) Pavement preloading:

[0058] To manufacture wheat straw boards with a homogeneous structure with a thickness of 20mm, take a sanding margin of 1.2mm, that is, set the thickness of the unsanded board produced by the press to 21.2mm, and set the density of the unsanded board to 820Kg / m 3 . According to these parameters, the raw materials after sizing are spread evenly on the metal backing plate, and the backing plate is treated with a release coating, and a release agent is sprayed on the upper surfac...

Embodiment 2

[0072] (1) Material preparation:

[0073] Wheat straw (place of origin: Guannan County, Lianyungang, Jiangsu Province) is pulverized for the first time by a hammer mill. The diameters of the double screens of the pulverizer are 8mm and 6mm respectively. , take 60% of it as the core material for board making. 40% of the pulverized material is pulverized by a hammer mill (screen diameters are 3mm and 3mm respectively) to be used as the surface layer material for board making. The moisture content of the surface material used for board making is 14.5%, and the moisture content of the core layer material used for board making is 10%. The surface layer material and the core layer material are sizing separately. In the mixer machine, the isocyanate (PMDI) adhesive is atomized and mixed with the surface layer material evenly, and then the core layer material is uniformly sized. The adhesive used was Huntsman Suprasec 5005, the sizing amount of the surface layer was 3.5% of the dry ...

Embodiment 3

[0086] (1) Material preparation:

[0087] Corn stalk husks (origin: Harbin, Heilongjiang) are pulverized for the first time by a hammer mill. The diameters of the double screens of the pulverizer are 10mm and 10mm respectively, and 60% of the pulverized raw materials are used as the core material for board making. 40% of the pulverized material is then pulverized by a hammer mill (the screen diameters are 3mm and 4mm respectively) to be used as the surface layer material for board making. The moisture content of the surface material used for board making is 15.5%, and the moisture content of the core layer material used for board making is 11%. The surface layer material and the core layer material are sizing separately. In the mixer machine, the isocyanate (PMDI) adhesive is atomized and mixed with the surface layer material evenly, and then the core layer material is uniformly sized. The adhesive used was Huntsman Suprasec 5005, the sizing amount of the surface layer was 3%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com