Single-walled carbon nanotube dispersion liquid and method for producing single-walled carbon nanotube dispersion liquid

A single-walled carbon nanotube and a manufacturing method technology, applied in the fields of nanostructure manufacturing, nanocarbon, nanotechnology, etc., can solve the problems that the single-walled carbon nanotube conductive film is not simple and the single-walled carbon nanotube is difficult to disperse, etc. Excellent transparency and conductivity, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] [Process X, 1]

[0092] Single-walled carbon nanotubes were produced by the arc discharge method. The produced single-walled carbon nanotubes were reacted in 63% nitric acid at 85° C. for 2 days (wet oxidation). Then, the single-walled carbon nanotubes are purified / recovered by filtration.

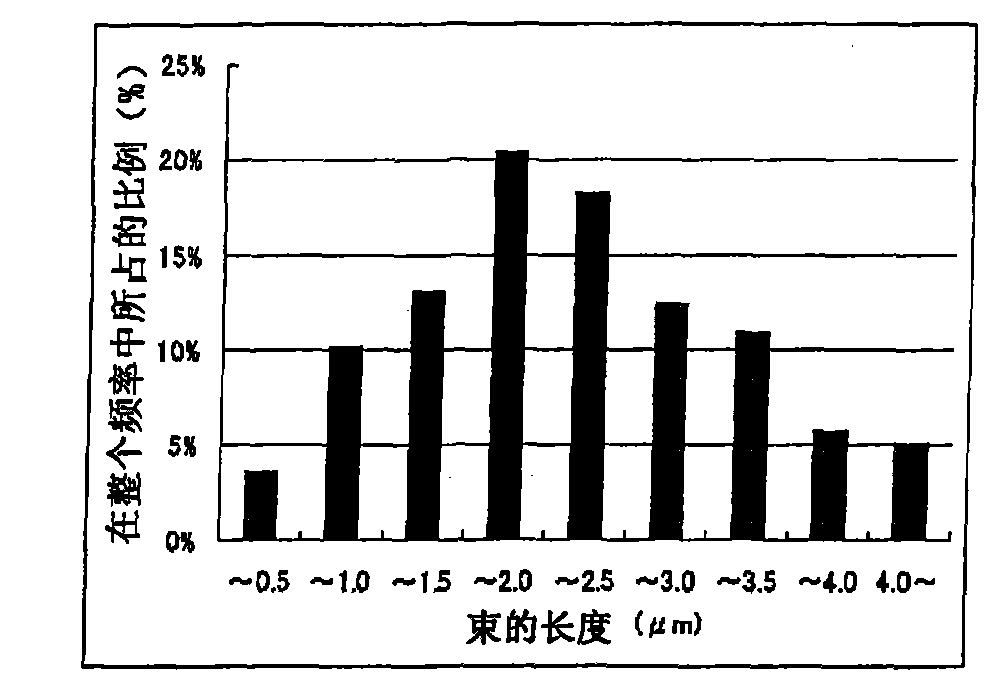

[0093] In addition, scanning electron micrographs of the purified SWNTs are shown in figure 1 . Furthermore, the measurement results of the bundle lengths of single-walled carbon nanotubes are shown in figure 2 . According to the frequency distribution per 0.5μm ( figure 2) shows that there is a mode in the range of 1.5 μm to 2.0 μm. Furthermore, the number of bundles of single-walled carbon nanotubes whose bundle length is greater than 1.5 μm accounted for 73% of the whole. The number of bundles of single-walled carbon nanotubes whose bundle length was 1.5 μm or less accounted for 27% of the whole. That is, it can be seen that the number of bundles of single-walled carbon...

Embodiment 2

[0105] A single-walled carbon nanotube dispersion was obtained in the same manner as in Example 1, except that the hydroxyl-containing fullerene in Example 1 was 0.3 mg and the sodium hydroxide was 0.03 mg.

[0106] Then, using this single-walled carbon nanotube dispersion liquid, it carried out similarly to Example 1, and obtained the polycarbonate plate with a transparent conductive film.

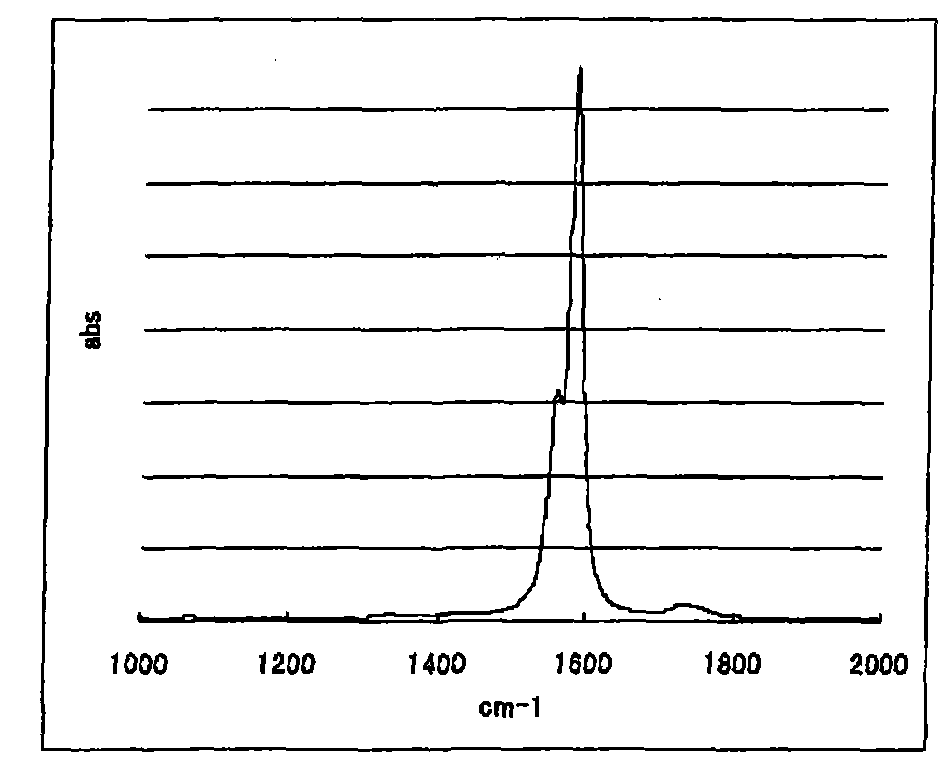

[0107] Furthermore, the concentration measurement results of single-walled carbon nanotubes and the like in the single-walled carbon nanotube dispersion liquid are shown in Figure 4 and Table 1.

Embodiment 3

[0109] A single-walled carbon nanotube dispersion was obtained in the same manner as in Example 1, except that the hydroxyl-containing fullerene in Example 1 was 1 mg and the sodium hydroxide was 0.1 mg.

[0110] Then, using this single-walled carbon nanotube dispersion liquid, it carried out similarly to Example 1, and obtained the polycarbonate plate with a transparent conductive film.

[0111] Furthermore, the concentration measurement results of single-walled carbon nanotubes and the like in the single-walled carbon nanotube dispersion liquid are shown in Figure 4 and Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com