Solder horn and laser soldering iron using same

A soldering iron head and laser technology, which is applied in the direction of soldering iron, laser welding equipment, manufacturing tools, etc., can solve the problems of shortened service life and easy loss, and achieve the effects of avoiding loss, uniform heat transfer, and fast conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

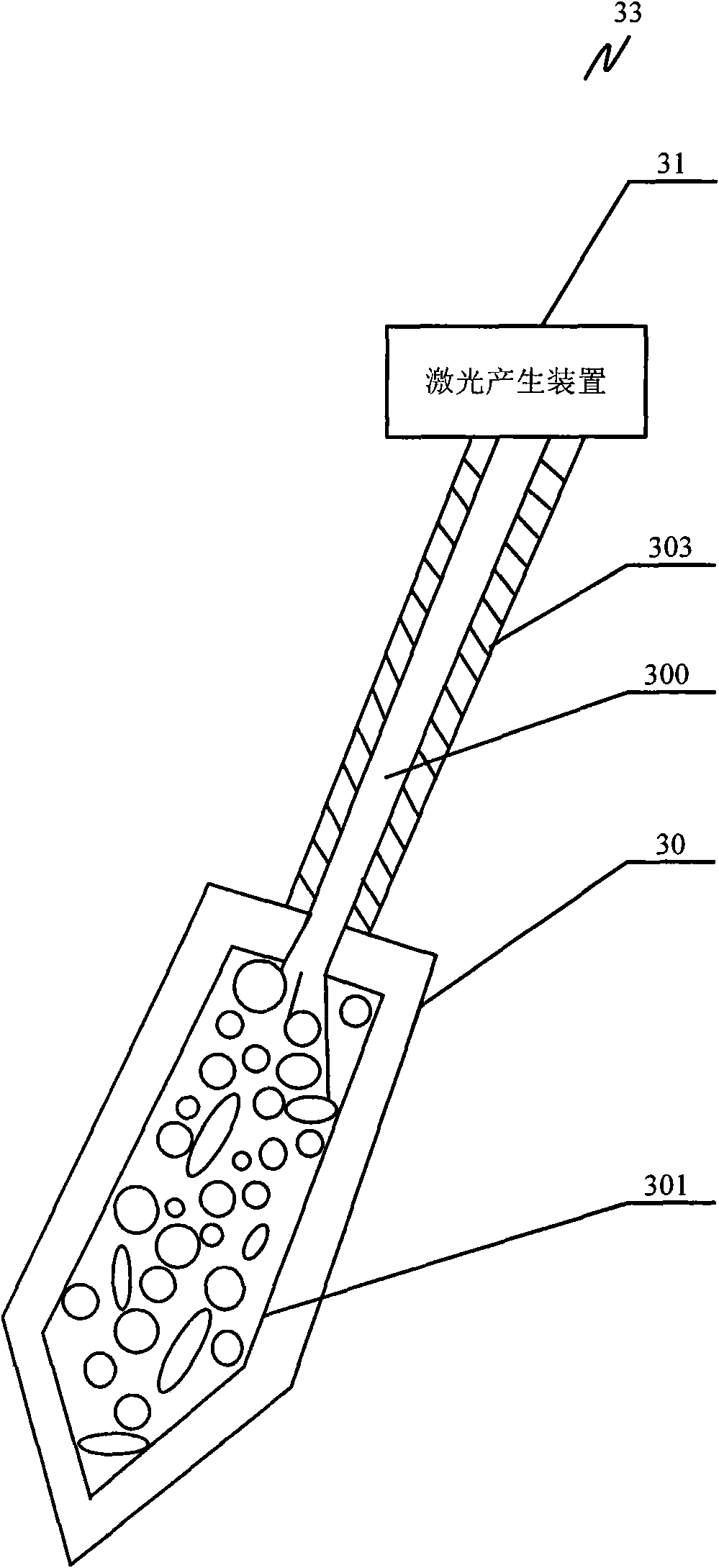

[0037] The main idea of the present invention is to set a hollow cavity in the soldering iron tip, and set a heat-resistant and heat-conducting material in the hollow cavity, so that the heat-resistant and heat-conducting material can be used as a conduction medium to rapidly diverge and conduct the laser light to the inner wall of the soldering iron tip. It has the characteristics of fast conduction and avoids the damage to the soldering iron tip caused by the excessive local heating of the soldering iron tip caused by the excessive concentration of the laser conduction route.

[0038] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

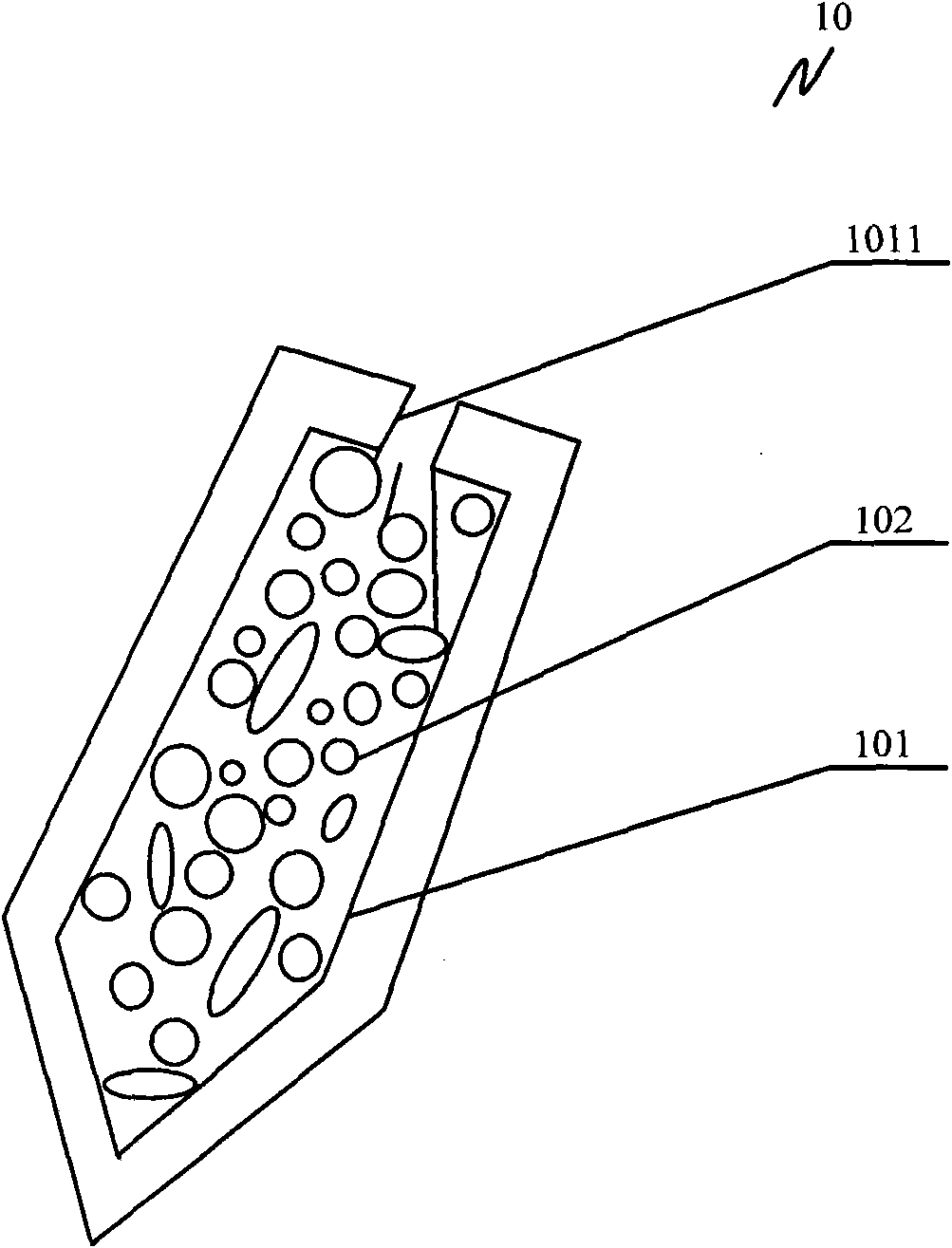

[0039] refer to figure 1 Shown is a schematic structural view of the first embodiment of the soldering iron tip of the present invention. The soldering iron tip 10 of this embodiment includes a cavity portion 101 , and a heat-resistant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com