Display device and manufacturing method thereof

A technology for display devices and manufacturing methods, applied in instruments, nonlinear optics, optics, etc., can solve the problems of no thinning, high energy consumption, increased volume and thickness of the backlight source, etc., and achieves fast dynamic response speed and transmittance. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0061] The first embodiment of the manufacturing method of the display device of the present invention includes:

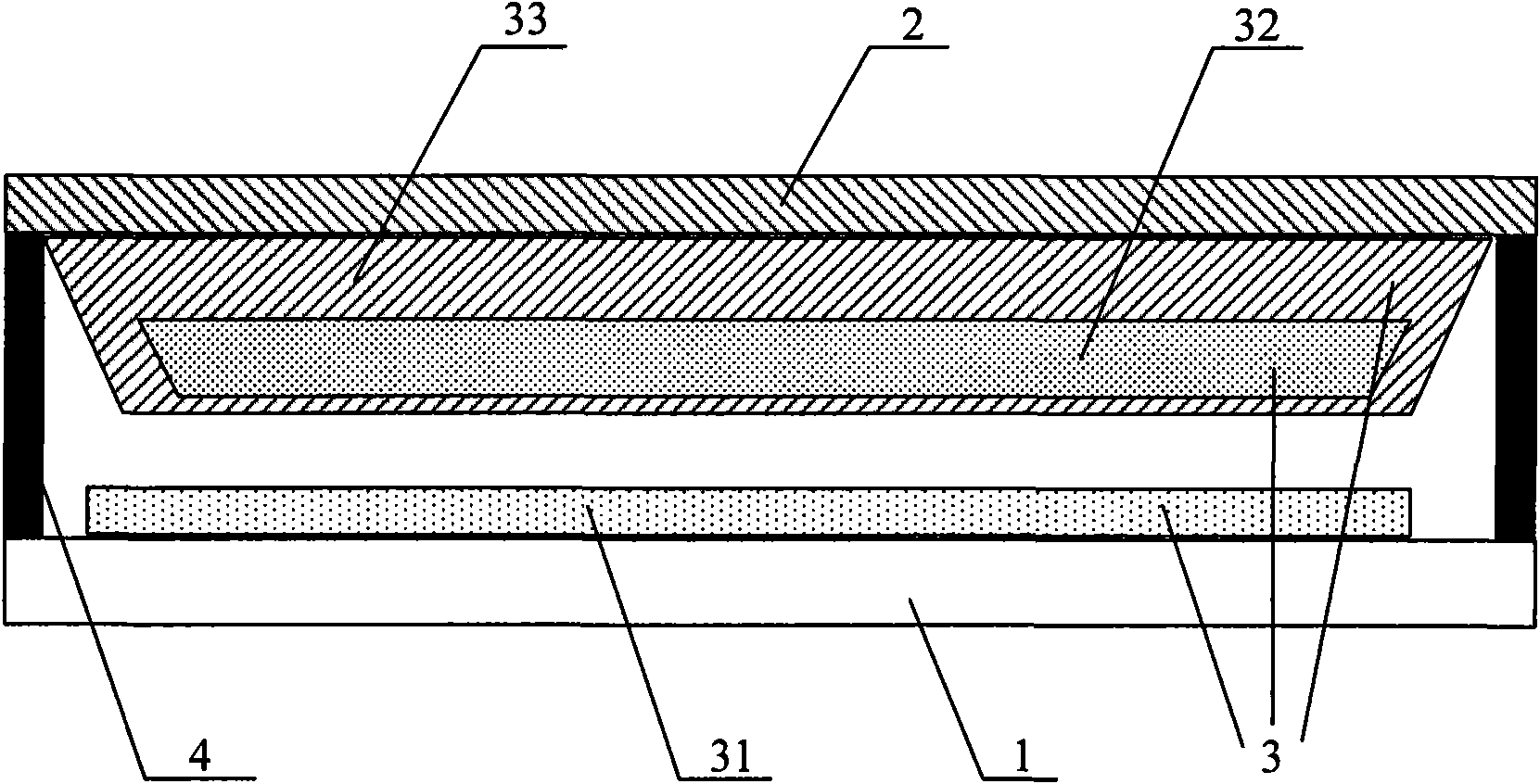

[0062] A color filter polymer with a magnetized ferromagnetic light-transmitting substance is attached on one surface of a glass substrate; a pixel electrode and its control unit are formed on one surface of a total internal reflection substrate; A spacer array is arranged around the color filter polymer; the glass substrate and the total internal reflection substrate are boxed.

[0063] Specifically, color filter polymers of three primary colors are pasted on the glass substrate, and their functions are the same as the color filter films in liquid crystal display devices, and are the necessary basis for producing color pictures. The substance is an organic polymer and therefore stretchable. The color filter polymer is embedded with a magnetized ferromagnetic light-transmitting material. At present, the magnetized ferromagnetic light-transmitting material formed ...

no. 3 example

[0076] The third embodiment of the manufacturing method of the display device of the present invention includes:

[0077] The pixel electrode and its control unit are formed on the glass substrate, and the color filter polymer embedded with the magnetized ferromagnetic light-transmitting substance is attached to the glass substrate on which the pixel electrode and its control unit have been formed; A spacer array is arranged around a color filter polymer; a glass substrate and a total internal reflection substrate are boxed.

[0078] The step of arranging the spacer array around the glass substrate on which the color filter polymer is attached can also adopt the method of arranging the spacer array at a corresponding position on a surface of the total internal reflection substrate.

[0079] The difference between this embodiment and the second embodiment of the method for manufacturing a display device of the present invention is that in this embodiment, the pixel electrode an...

no. 4 example

[0082] The fourth embodiment of the manufacturing method of the display device of the present invention includes:

[0083] The color filter polymer embedded with the magnetized ferromagnetic light-transmitting substance is attached to the glass substrate; the pixel electrode and its control unit are formed on the surface of the color filter polymer; the color filter polymer is attached to the glass substrate A spacer array is arranged around the object; the glass substrate and the total internal reflection substrate are boxed.

[0084] The step of arranging the spacer array around the glass substrate on which the color filter polymer is attached can also adopt the method of arranging the spacer array at a corresponding position on a surface of the total internal reflection substrate.

[0085] In this embodiment, the color filter polymer embedded with the magnetized ferromagnetic light-transmitting substance is attached on the glass substrate, and then the pixel electrode and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com