Waterproof heat insulating brick and manufacturing and construction methods thereof

A technology of thermal insulation and thermal insulation layer, which is applied in the direction of manufacturing tools, building structures, roof coverings, etc., can solve the problems of failure of waterproof thermal insulation function, short service life of waterproof materials, and the problem of water leakage in flat houses. Achieve good anti-aging performance, strong waterproof performance, and superior waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

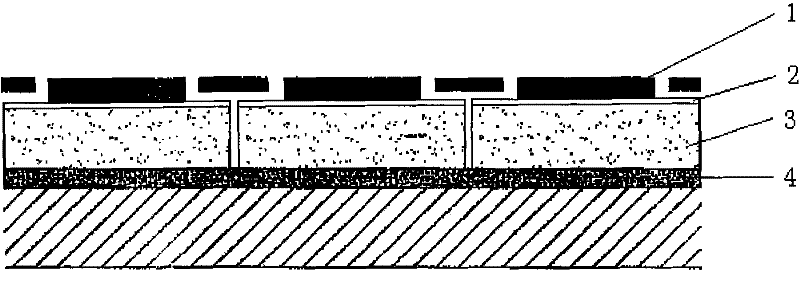

[0018] The present invention consists of a brick body, the above-mentioned brick body is composed of a rigid waterproof layer 1, a flexible waterproof layer 2 and a thermal insulation layer 3, wherein the thermal insulation layer 3 is located at the lower part of the brick body, and the upper part of the thermal insulation layer 3 is set Flexible waterproof layer 2, the flexible waterproof layer 2 includes polyethylene polypropylene fiber waterproof material, the upper part of the flexible waterproof layer 2 is provided with a rigid waterproof layer 1, the rigid waterproof layer 1 is located in the middle of the flexible waterproof layer 2, and the entire brick body is in the shape of a "convex" ,Such as figure 1 shown.

[0019] The rigid waterproof layer 1 includes waterproof concrete and admixtures. In the waterproof concrete, fine sand and gravel are mixed into gravel at a mass ratio of 30:100, the mass ratio of cement to sand is 1:2, and the mass ratio of water to cement ...

Embodiment 2

[0024] The present invention consists of a brick body, the above-mentioned brick body is composed of a rigid waterproof layer 1, a flexible waterproof layer 2 and a thermal insulation layer 3, wherein the thermal insulation layer 3 is located at the lower part of the brick body, and the upper part of the thermal insulation layer 3 is set Flexible waterproof layer 2, the flexible waterproof layer 2 includes polyethylene polypropylene fiber waterproof material, the upper part of the flexible waterproof layer 2 is provided with a rigid waterproof layer 1, the rigid waterproof layer 1 is located in the middle of the flexible waterproof layer 2, and the entire brick body is in the shape of a "convex" ,Such as figure 1 shown.

[0025] The rigid waterproof layer 1 includes concrete and admixtures. In the concrete, fine sand and gravel are mixed into gravel at a mass ratio of 32:100. The mass ratio of cement to sand is 1:2.1, and the mass ratio of water to cement is 47. : 100. In th...

Embodiment 3

[0031]The present invention consists of a brick body, the above-mentioned brick body is composed of a rigid waterproof layer 1, a flexible waterproof layer 2 and a thermal insulation layer 3, wherein the thermal insulation layer 3 is located at the lower part of the brick body, and the upper part of the thermal insulation layer 3 is set Flexible waterproof layer 2, the flexible waterproof layer 2 includes polyethylene polypropylene fiber waterproof material, the upper part of the flexible waterproof layer 2 is provided with a rigid waterproof layer 1, the rigid waterproof layer 1 is located in the middle of the flexible waterproof layer 2, and the entire brick body is in the shape of a "convex" ,Such as figure 1 shown.

[0032] The rigid waterproof layer 1 includes concrete and admixtures. In the concrete, fine sand and stones are mixed into gravel at a mass ratio of 35:100, the mass ratio of cement to sand is 1:2.2, and the mass ratio of water to cement is 49 : 100. In this...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com