Non electric-conduction vacuum plating UV dope

A vacuum electroplating, non-conductive technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of few reports on coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

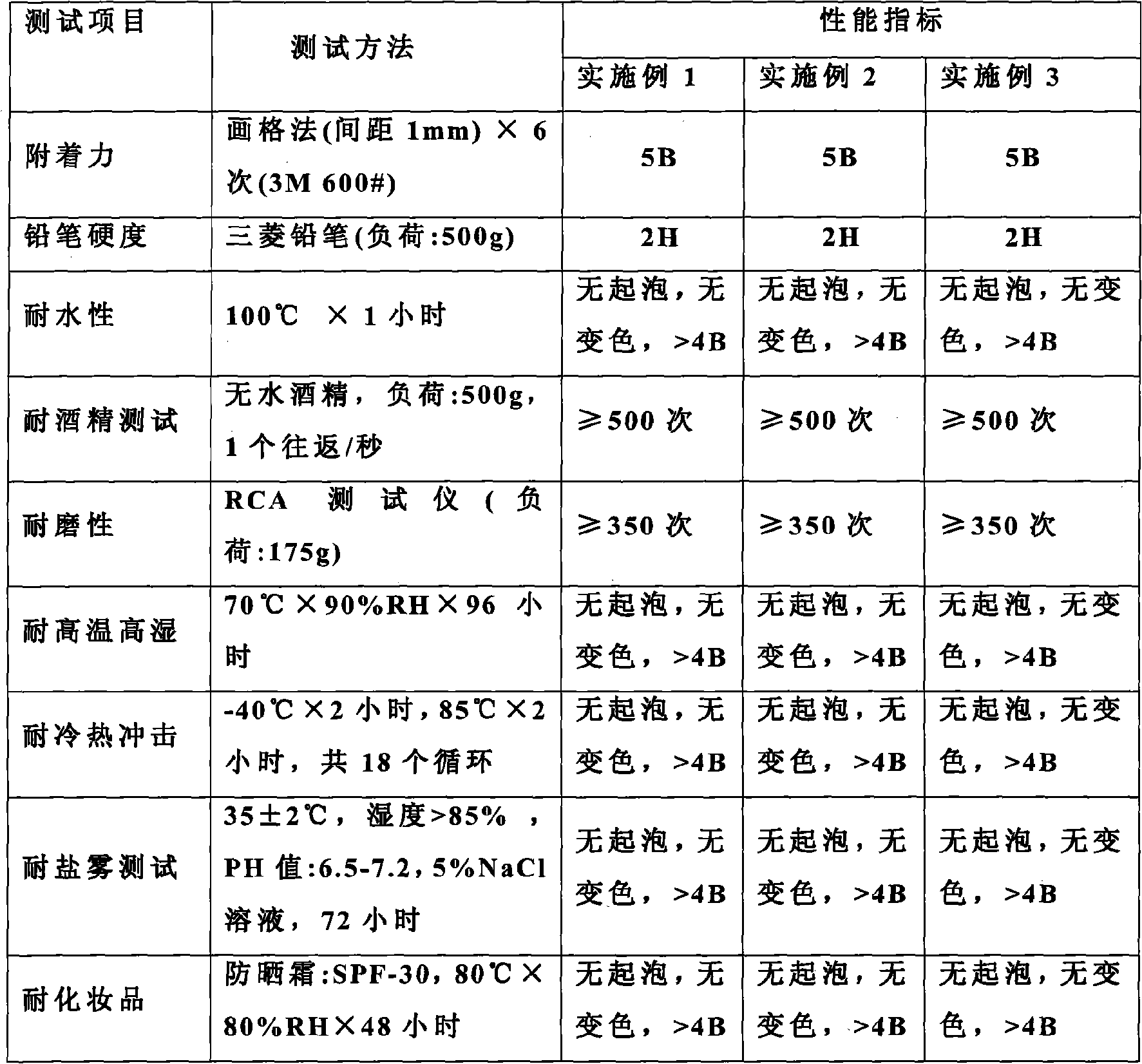

Embodiment 1

[0034] According to the primer of the non-conductive vacuum electroplating UV paint of the present embodiment, it consists of: 15% of difunctional polyurethane acrylate resin, 10% of epoxy-modified acrylate resin, trihydroxymethyl propane trimethacrylate 15%, isobornyl acrylate 10%, 1-hydroxycyclohexyl phenyl ketone 2%, benzoin dimethyl ether 1%, methyl ethyl ketone 26.3%, xylene 20%, acrylate copolymer leveling agent 0.5%, alkyl Organosiloxane copolymer 0.2%.

[0035] The above primer is prepared by the following method: mix methyl ethyl ketone, xylene, 1-hydroxycyclohexyl phenyl ketone, and benzoin dimethyl ether according to the stated ratio, stir in a high-speed disperser at a speed of 800 to 1000 rpm until uniform, and then Add functional group urethane acrylate resin, epoxy-modified acrylate resin, trihydroxymethylpropane trimethacrylate, and acrylate isobornyl ester into the high-speed disperser in proportion, and in the high-speed disperser with Stir at 1000rpm until ...

Embodiment 2

[0039] According to the primer of the non-conductive vacuum electroplating UV coating of the present embodiment, it consists of: 18% of difunctional polyurethane acrylate resin, 8% of epoxy-modified acrylate resin, trihydroxymethyl propane trimethacrylate 18%, isobornyl acrylate 6%, 1-hydroxycyclohexyl phenyl ketone 2.5%, benzoin dimethyl ether 0.5%, methyl ethyl ketone 30%, xylene 16.5%, acrylate copolymer leveling agent 0.3%, alkyl Organosiloxane copolymer 0.2%.

[0040] The preparation method of primer is with embodiment 1.

[0041] According to the top coat of the non-conductive vacuum electroplating UV coating of the present embodiment, it is composed of: 15% of six-functional polyurethane acrylate resin, 10% of solvent-type modified acrylate resin, 12% of propoxylated glycerin triacrylate, tetrahydrofuran Acrylate 8%, pentaerythritol tetraacrylate 5%, 1-hydroxycyclohexyl phenyl ketone 3%, methyl ethyl ketone 35%, xylene 11.6%, acrylate copolymer leveling agent 0.3%, alk...

Embodiment 3

[0044] A primer for non-conductive vacuum electroplating UV paint, which consists of: 20% of difunctional polyurethane acrylate resin, 5% of epoxy modified acrylate resin, 20% of trihydroxymethyl propane trimethacrylate, Acrylate isobornyl ester 5%, 1-hydroxycyclohexyl phenyl ketone 2.5%, benzoin dimethyl ether 0.5%, methyl ethyl ketone 30%, xylene 16.5%, acrylate copolymer leveling agent 0.3%, alkyl organosiloxane alkane copolymer 0.2%.

[0045] The preparation method of primer is with embodiment 1.

[0046] According to the top coat of the non-conductive vacuum electroplating UV coating of the present embodiment, it is composed of: 12% of six-functional polyurethane acrylate resin, 12% of solvent-type modified acrylate resin, 10% of propoxylated glycerin triacrylate, tetrahydrofuran Acrylate 10%, pentaerythritol tetraacrylate 3%, 1-hydroxycyclohexyl phenyl ketone 3%, methyl ethyl ketone 35%, xylene 14.7%, acrylate copolymer leveling agent 0.25%, alkyl organosiloxane copolym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com