Method for preparing high-temperature resistant antibacterial non-stick paint

A non-stick coating, high temperature resistant technology, applied in anti-fouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problem of easy breeding of bacteria, etc., and achieve obvious non-stick effect, obvious antibacterial effect, cost low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

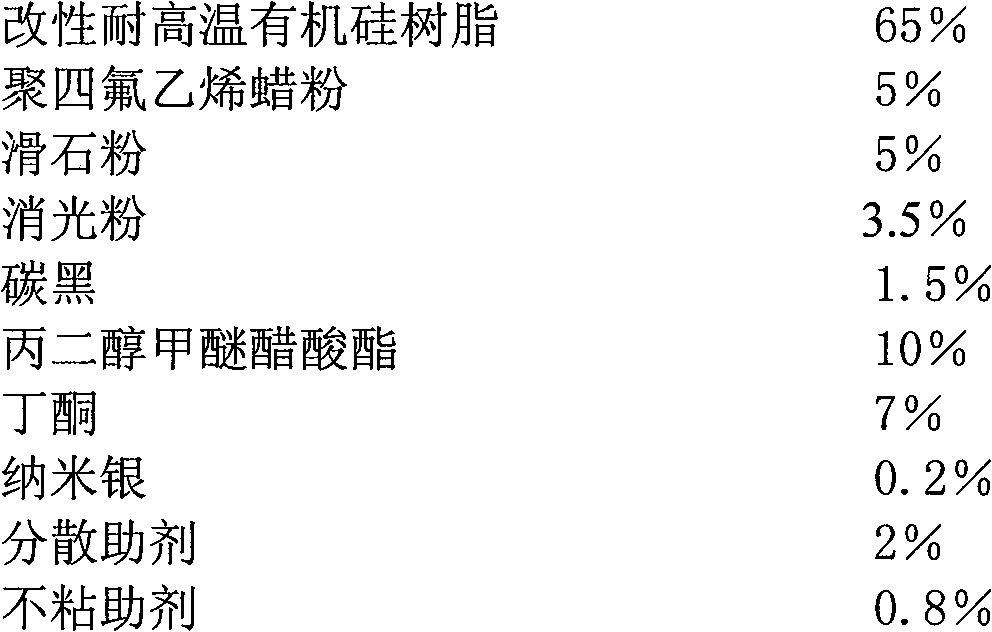

[0014] Modified high temperature resistant silicone resin 65%

[0015] PTFE wax powder 5%

[0016] Talc 5%

[0017] Matting Powder 3.5%

[0018] Carbon black 1.5%

[0019] Propylene glycol methyl ether acetate 10%

[0020] Butanone 7%

[0021] Nano silver 0.2%

[0022] Dispersion aid 2%

[0023] Non-stick additive 0.8%

[0024] The manufacturing method of this embodiment is:

[0025] 1) First, put the modified high-temperature resistant silicone resin, polytetrafluoroethylene wax powder, talc powder, carbon black, nano-silver, propylene glycol methyl ether acetate, methyl ethyl ketone, and dispersing aid into a conventional dispersing machine for medium-speed dispersion 20-30 minutes;

[0026] 2) Mix and disperse, put talcum powder, carbon black, nano-silver, and matting powder into the original grinding machine for dispersing resin and additives, and make them grind and disperse at high speed together, and grind at high speed for 2-3 hours until the fineness less th...

specific Embodiment 2

[0030] Modified high temperature resistant silicone resin 65%

[0031] PTFE wax powder 5%

[0032] Talc 5%

[0033] Matting Powder 3.5%

[0034] Carbon black 1.5%

[0035] Propylene glycol methyl ether acetate 10%

[0036] Butanone 6.8%

[0037] Nanosilver 0.4%

[0038] Dispersion aid 2%

[0039] Non-stick additive 0.8%

[0040] The manufacturing method of this embodiment is:

[0041] 1) First, put the modified high-temperature resistant silicone resin, polytetrafluoroethylene wax powder, talc powder, carbon black, nano-silver, propylene glycol methyl ether acetate, methyl ethyl ketone, and dispersing aid into a conventional dispersing machine for medium-speed dispersion 20-30 minutes;

[0042] 2. Mix and disperse, put talcum powder, carbon black, nano-silver, and matting powder into the original grinding machine for dispersing resin and additives, and make them work together for high-speed grinding and dispersing, and high-speed grinding for 2-3 hours until the finen...

specific Embodiment 3

[0045] Modified high temperature resistant silicone resin 65%

[0046] PTFE wax powder 5%

[0047] Talc 5%

[0048] Matting Powder 3.5%

[0049] Carbon black 1.5%

[0050] Propylene glycol methyl ether acetate 10%

[0051] Butanone 6.6%

[0052] Nano silver 0.6%

[0053] Dispersion aid 2%

[0054] Non-stick additive 0.8%

[0055] The manufacturing method of this embodiment is:

[0056] 1) First, put the modified high-temperature resistant silicone resin, polytetrafluoroethylene wax powder, talc powder, carbon black, nano-silver, propylene glycol methyl ether acetate, methyl ethyl ketone, and dispersing aid into a conventional dispersing machine for medium-speed dispersion 20-30 minutes;

[0057] 2 Mix and disperse, put talcum powder, carbon black, nano-silver, and matting powder into the original grinding machine for dispersing resin and additives, and make them grind and disperse at high speed together, and grind at high speed for 2-3 hours until the fineness is less t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com