Mechanical arm failure protecting device

A fail-safe, robotic arm technology, used in manipulators, manufacturing tools, etc., can solve problems such as simple procedures, price, loss of control of robotic arms, accidents, etc., to improve essential reliability, achieve reliable protection, and improve reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

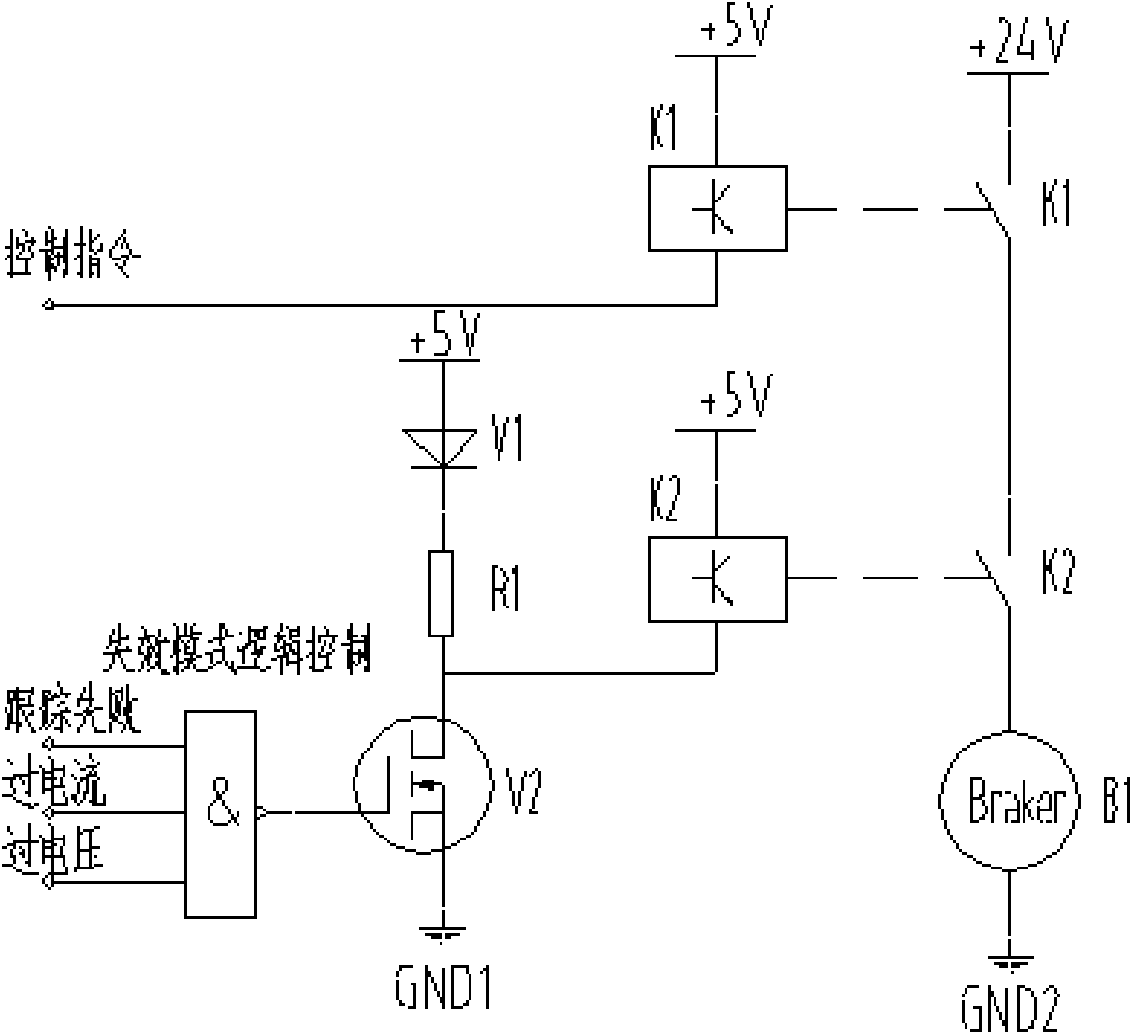

[0013] Such as figure 1 As shown, the first relay K1, the second relay K2, and the brake B1 form the main control circuit, and the first relay K1 and the second relay K2 are respectively solid state relays. The diode V1, the resistor R1, the MOS transistor V2, and the failure control logic are connected to form a failure mode control circuit. The first relay K1 is connected to the operation control signal of the manipulator, and the brake B1 is connected to the motor shaft of the joint of the manipulator. The collector of MOS transistor V2 is connected to high level, the emitter is connected to ground, and the base is connected to the failure control logic. The failure control logic receives the failure signals of the mechanical arm, including tracking failure, overvoltage, and overcurrent signals, and sends them after logic processing. to the base of the MOS transistor V2, and the second relay is connected to the collector of the MOS transistor.

[0014] The brake B1 is a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com