Nitrogen heat cycle method of active coke dry-process desulfurizer

A desulfurization device and activated coke technology, applied in separation methods, chemical instruments and methods, combustible gas purification, etc., can solve problems such as heat loss, equipment corrosion, accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] Example: Take the dry-process activated coke flue gas desulfurization device of Wengfu (Group) Co., Ltd. as an example. This device is the first dry-process activated coke flue gas desulfurization device in China. smoke. The specific implementation is as follows:

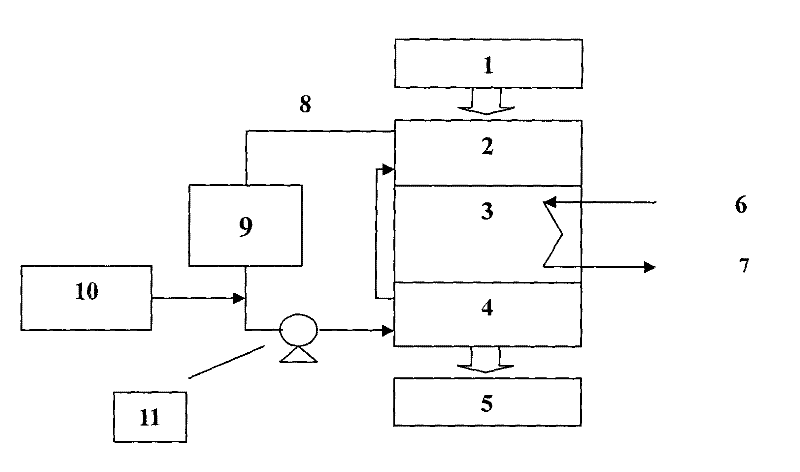

[0018] Combination of desorption tower active coke and heat exchange process in the process figure 1 Explanation: In specific operations,

[0019] Has adsorbed SO 2 The saturated activated coke flows from the adsorption tower 1 into the desorption tower, and flows through the preheating section 2, heating and desorption section 3, and cooling section 4 respectively. After the desorption is qualified, it is sent back to the adsorption tower for cyclic adsorption by bucket elevators.

[0020] The heating analysis section relies on 6 inlets of medium-pressure superheated steam and 7 outlets of medium-pressure superheated steam introduced from the outside to heat up to the analysis temperature so that the acti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com