Green pellet and pellet ore preparation method

A technology of green pellets and pellets, which is applied in the field of green pellets and pellets preparation, to achieve the effect of reducing the liquid phase formation temperature and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

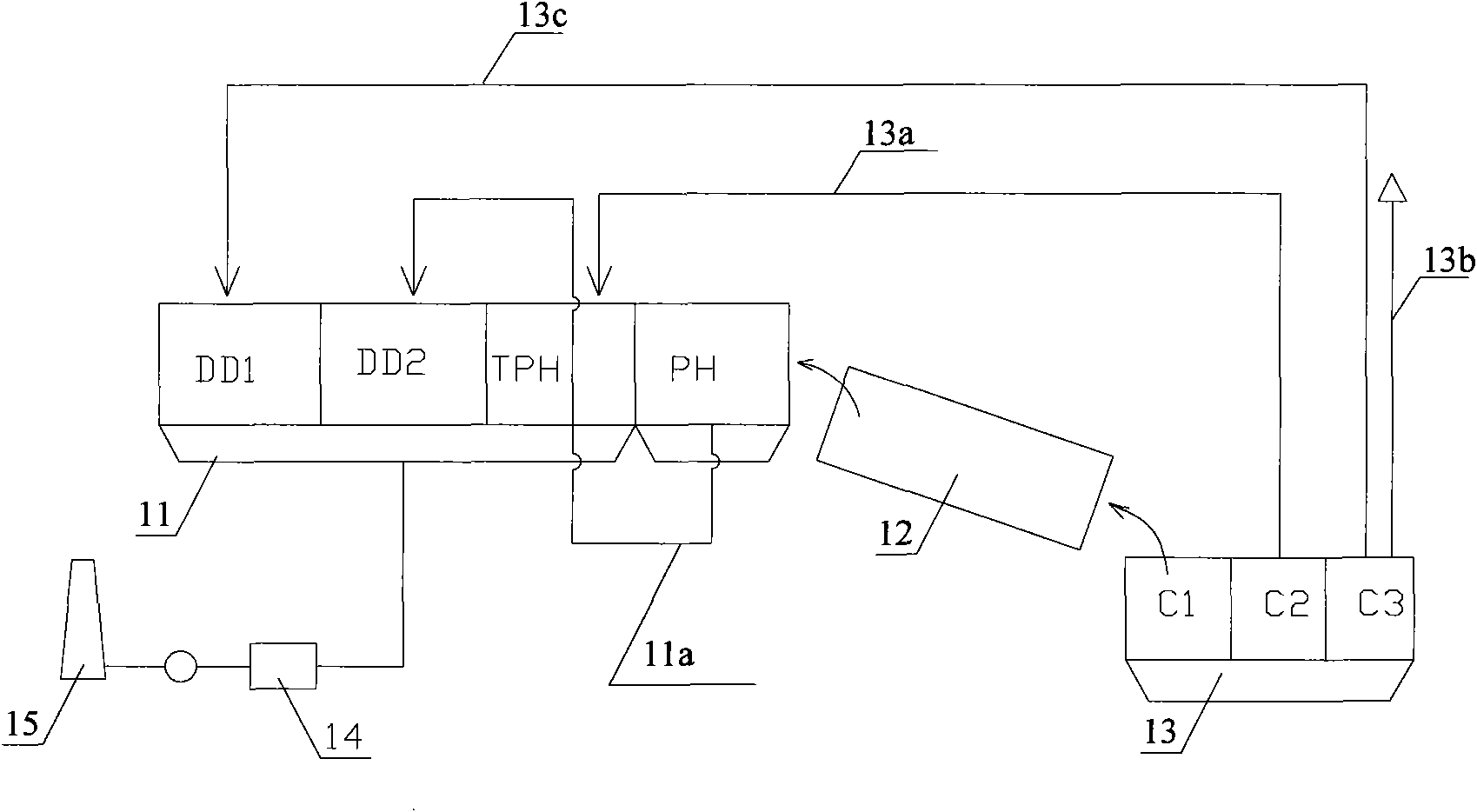

[0054] Design grate machine-rotary kiln according to a kind of implementation mode of pelletizing device of the present invention, main design parameter is as follows:

[0055] Grate machine specifications: 4m (width) × 37.5m (length), the length of the first drying section is 7.5m, the set temperature is 230°C, the wind speed of the material surface is 1.5m / s; the length of the second drying section is 7.5m, and the set temperature is 360 ℃, the wind speed at the material surface is 1.2m / s; the length of the first preheating section is 7.5m, the set temperature is 700°C, and the wind speed at the material surface is 1.0m / s; the length of the second preheating section is 15m, and the set temperature is 1100°C. The wind speed on the surface of the material is 0.7m / s; the first-stage drying and the second-stage drying are both exhausted drying methods.

[0056] Rotary kiln set temperature: 1320°C.

[0057] Ring cooler specifications: diameter 12.5m, width 2.2m, effective coolin...

Embodiment 2

[0063] The difference from Example 1 is that the following process design parameters have been changed: the set temperature of the first drying section is 220°C, and the wind speed of the material surface is 1.4m / s; the set temperature of the second drying section is 340°C, and the wind velocity of the material surface is 1.3m / s s,; the set temperature of the first preheating section is 680°C, and the wind speed of the material surface is 1.1m / s; the set temperature of the second preheating section is 1080°C, and the wind velocity of the material surface is 0.7m / s; The first-stage drying is the exhaust drying method; the set temperature of the rotary kiln is 1300° C.; other parameters are the same as in Example 1.

[0064] Raw material ratio: 41.4wt% of Brazilian hematite and sulfuric acid slag, 14.8wt% of magnetite, 1.5wt% of bentonite, 0.9wt% of dolomite. The water content is 11.6wt%, the burst temperature is 430°C, and the binary alkalinity is 0.35.

[0065] Send the raw p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Burst temperature | aaaaa | aaaaa |

| Water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com