Water cooling structure of microwave oven magnetron

A magnetron and water cooling technology, applied in the field of magnetron, can solve the problems of low heat dissipation and cooling efficiency, limited heat dissipation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

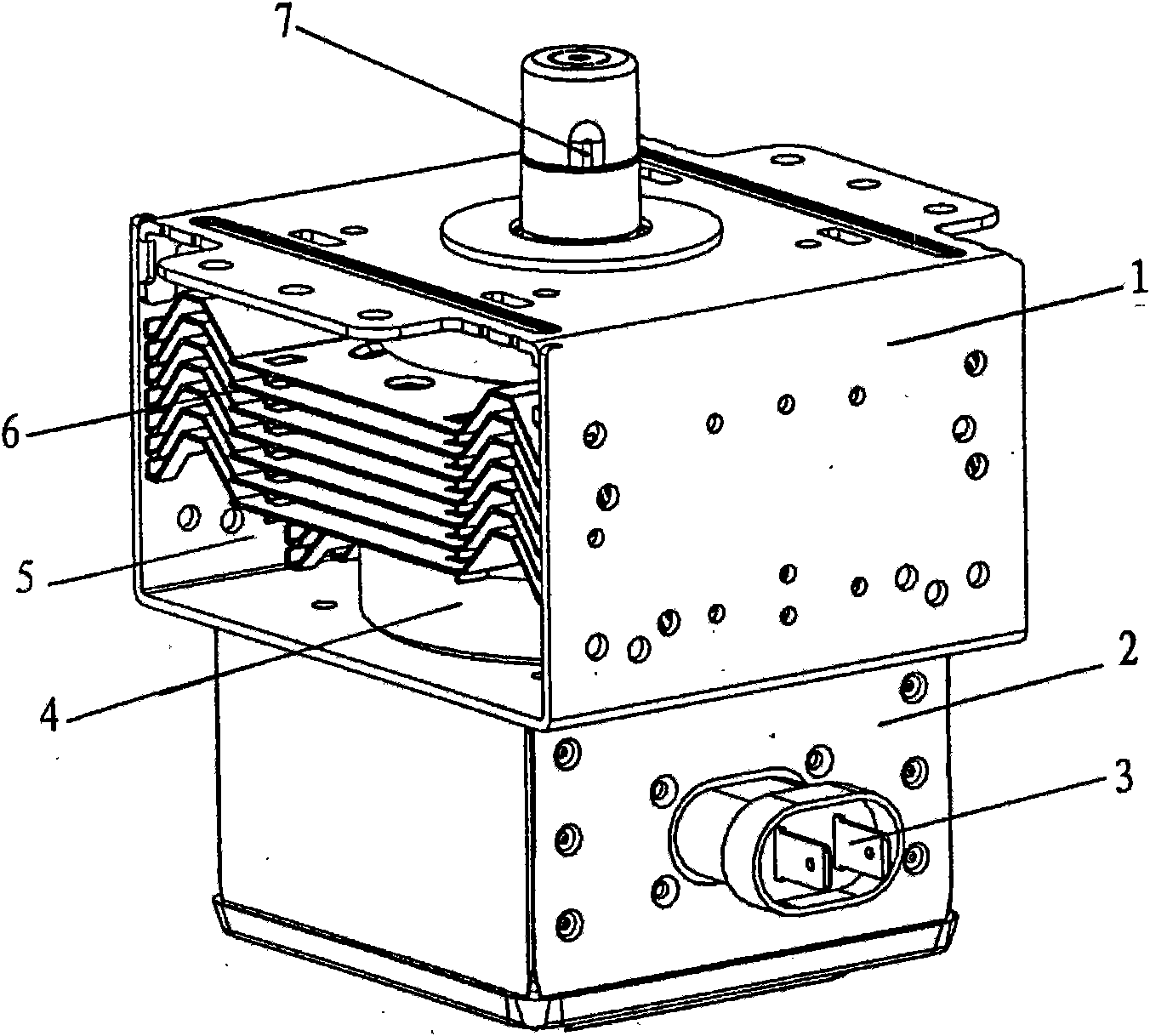

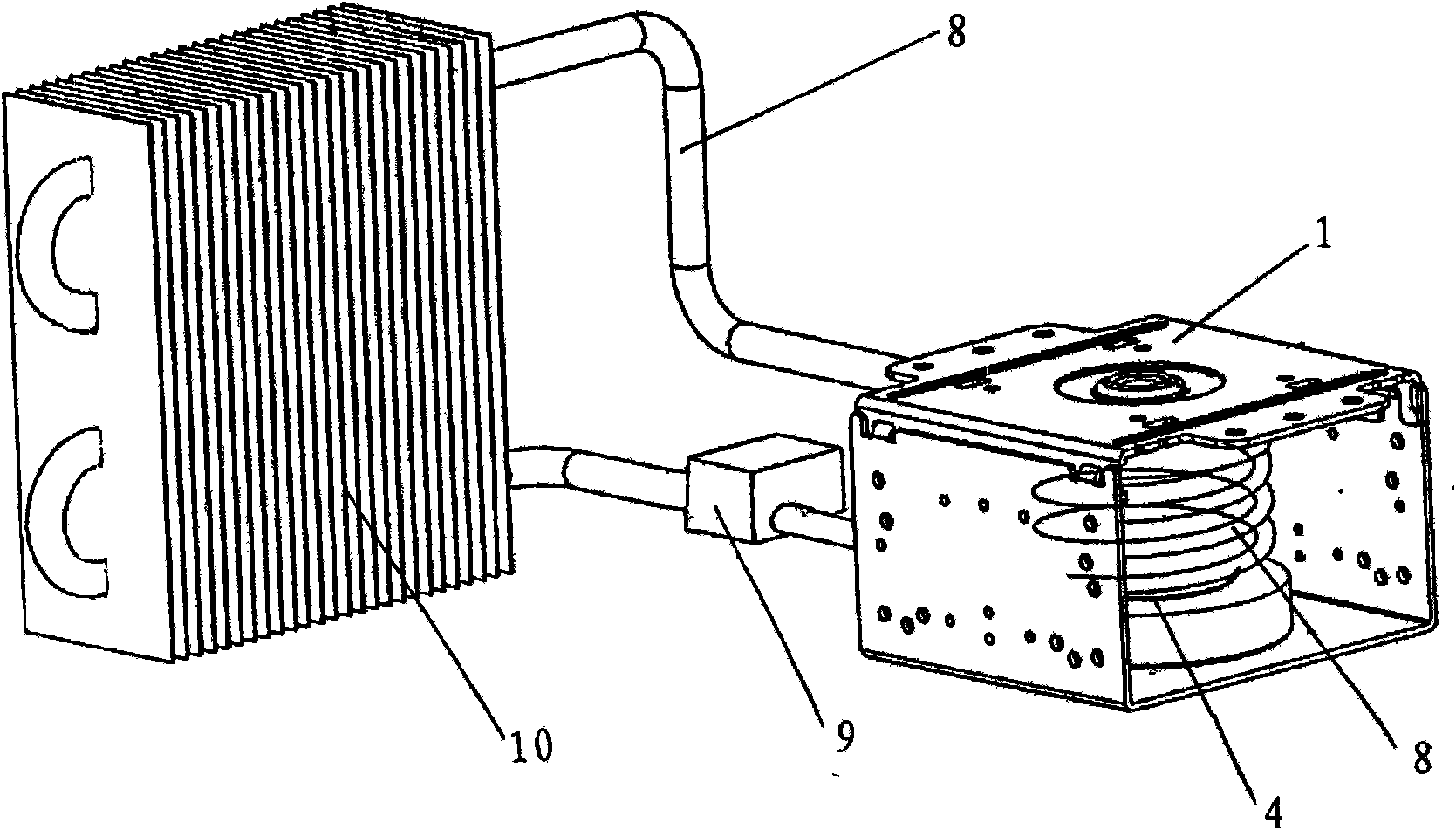

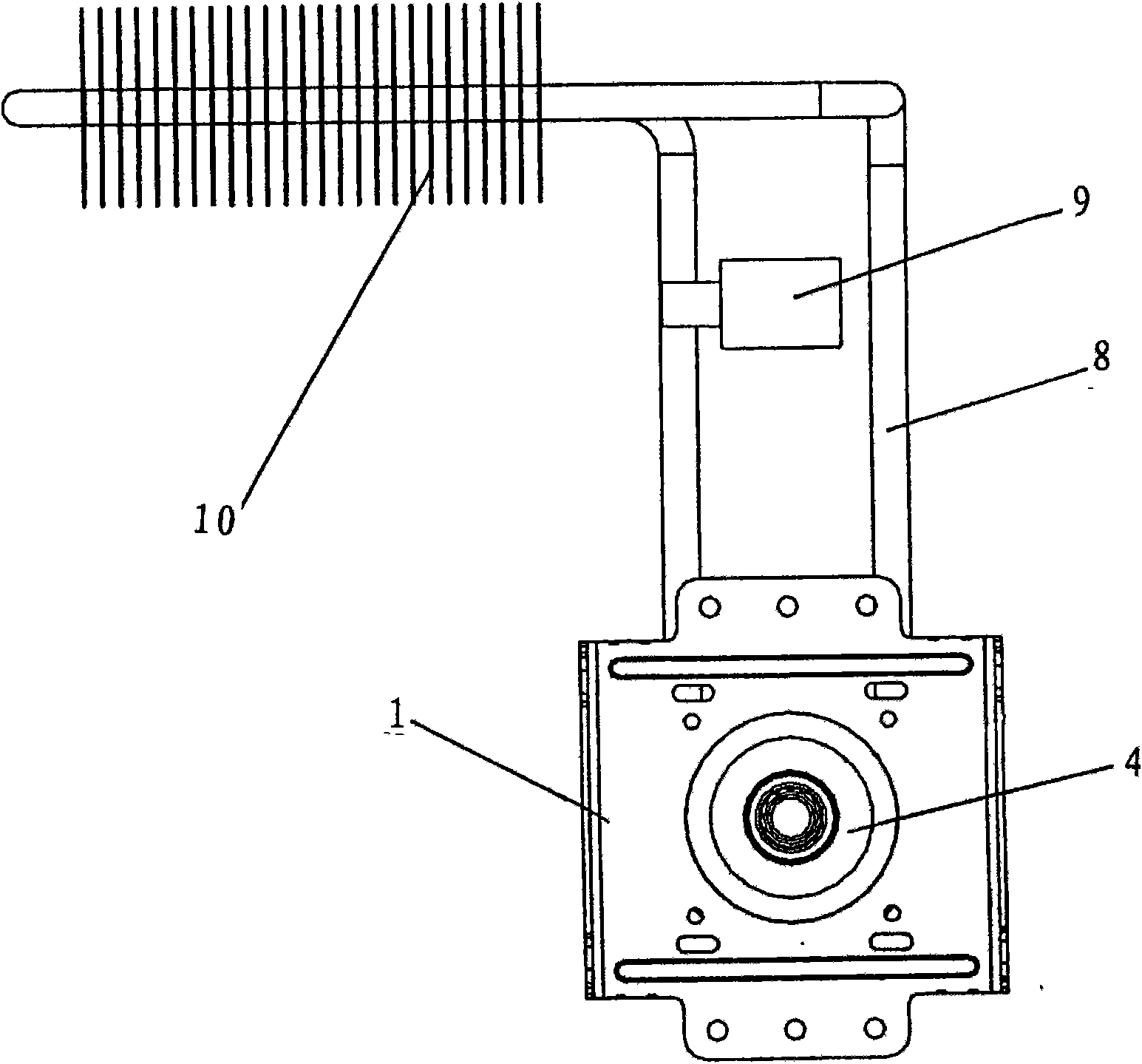

[0019] Now in conjunction with the accompanying drawings, the present invention will be further described. figure 2 It is a schematic diagram of the microwave oven magnetron water cooling structure of the present invention. image 3 It is a schematic cross-sectional view of the microwave oven magnetron water cooling structure of the present invention.

[0020] Such as figure 2 and image 3 As shown, the microwave oven magnetron water cooling structure involved in the present invention includes a circulating water pipe 8, a water pump 9 and fins 10, the water pump 9 is connected to the circulating water pipe 8, a part of the water pipe is wound on the copper sleeve 4 outside the anode, and a part of the water pipe Fins 10 are provided on the outside. The water pipe 8 is a copper pipe with high thermal conductivity, and the fins 10 are made of aluminum alloy. The fins 10 are alternately arranged on the water pipe 8 and are perpendicular to the passing water pipe.

[0021]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com