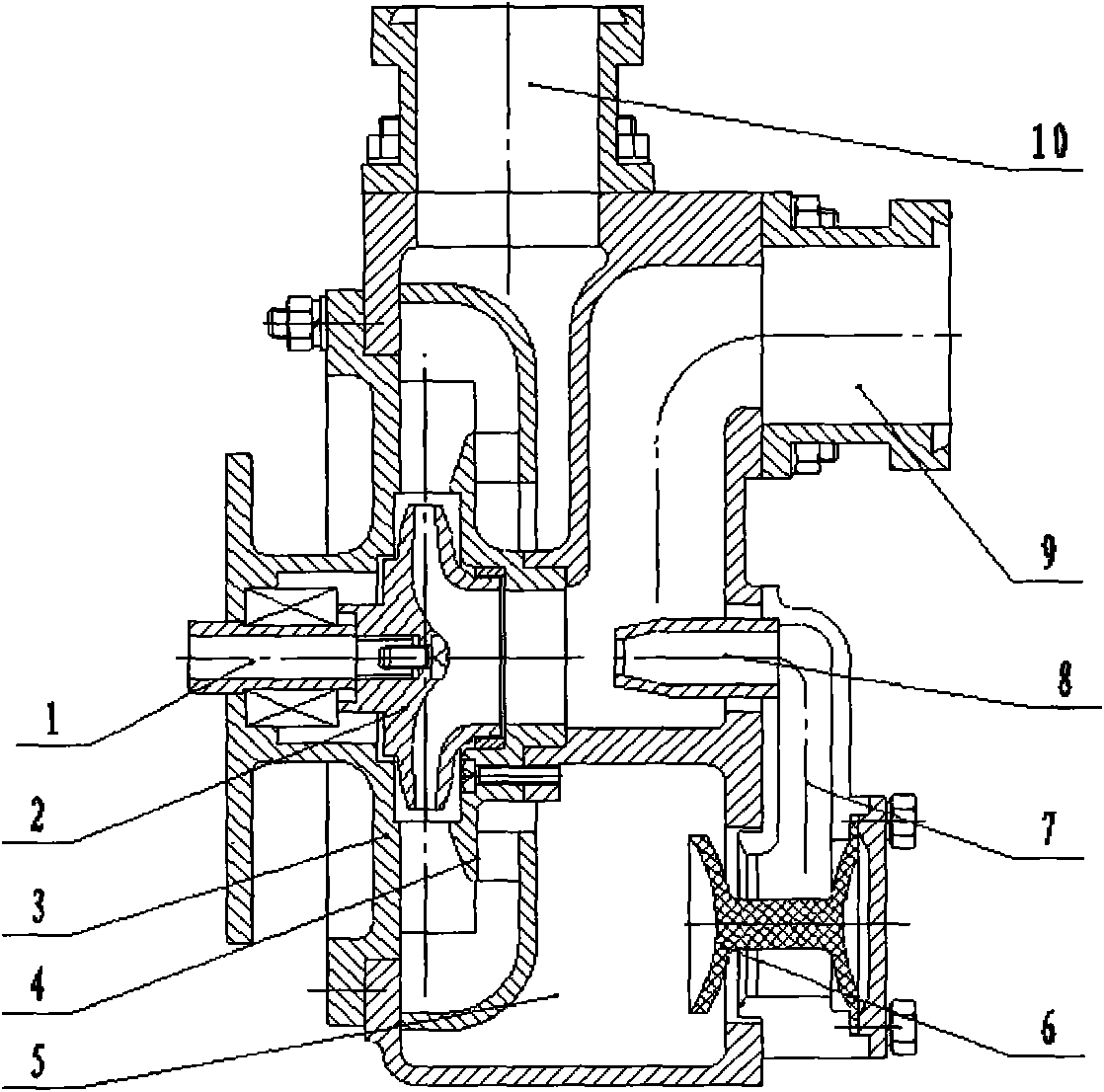

New structure of self-priming centrifugal pump

A technology of self-priming centrifugal pump and new structure, which is applied in the direction of pumps, drive pumps, non-variable pumps, etc. It can solve the problems of slow self-priming, complex structure, low efficiency, etc., and achieve fast self-priming time and good economic benefits , good workmanship effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

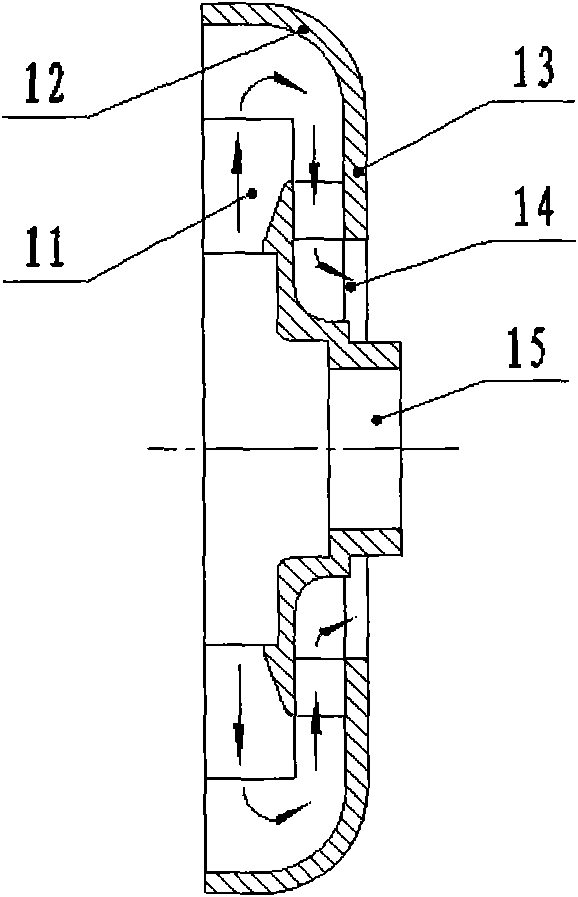

[0011] exist figure 2 In the process, the liquid flows into the inlet [15] at high speed, flows from the guide vane [11] to the flow channel of the guide vane radial sealing cover [12], and passes through the outlet of the guide vane, which reduces the impact loss of the pump and improves the efficiency of the pump; The speed circulation of the pump is reduced, the gas-liquid mixing speed of the pump is accelerated, and the self-priming time of the pump is increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com