Molybdenum wire balancer for numerically controlled wire-cut electric discharge machine

A technology for cutting machine tools and EDM wires, used in electrode manufacturing, electric machining equipment, metal processing equipment, etc., can solve the problems of molybdenum wire jitter, reduction of workpiece surface roughness, etc., and achieve the effect of solving jitter and swing problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

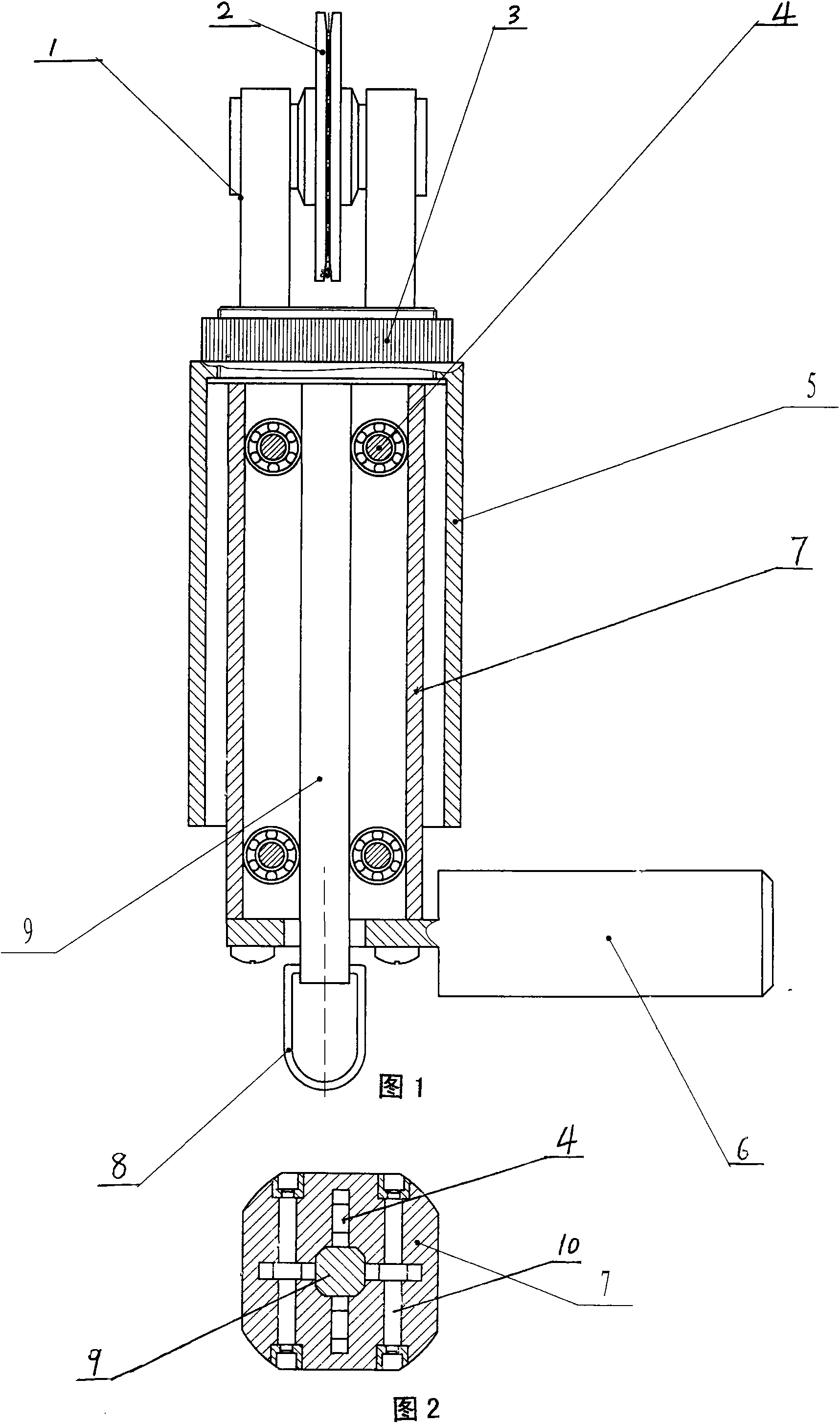

[0009] Refer to attached figure 1 , 2 , it includes a guide groove body 7, the lower part of the guide groove body is connected and fixed with the positioning shaft 6, the outer cover of the guide groove body is covered with a housing 5, the guide groove body is equipped with a guide rod 9, and there are several bearings 4 around the upper and lower parts of the guide rod. Dynamic contact, the bearings are installed on the respective limit shafts 10, the two ends of the limit shafts are fixed on the inner wall of the guide groove, the upper end of the guide rod protrudes from the opening of the guide groove body and the top of the housing, and is connected and fixed with the bracket 1 , The guide wheel 2 is installed on the bracket through the shaft, the lock nut 3 is installed above the housing, the lower end of the guide rod protrudes from the opening of the lower end of the guide groove body, and the end is provided with a suspension ring 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com