Filtering agent for harmful gas in cigarette, production method thereof and application thereof

A technology of harmful gas and production method, which is applied in the direction of e-liquid filter elements, tobacco, applications, etc., can solve the problems of not being able to significantly improve the filtering of some harmful gases, the effect of reducing harm and reducing tar is not obvious, and changing the original taste, etc., to achieve cell oxidation Membrane damage, cytotoxicity and immunotoxicity are reduced, sensory quality is improved, and aroma is increased

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

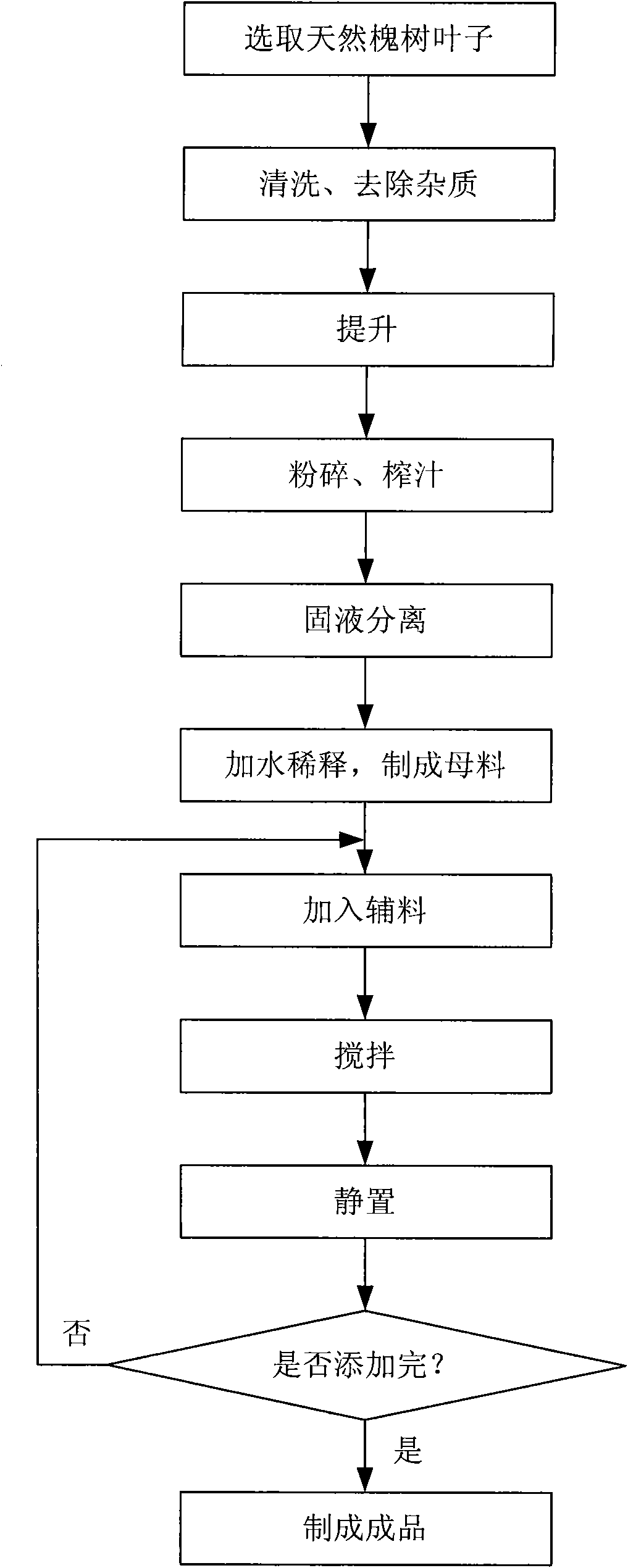

[0031] The invention provides a production method of a harmful gas filter agent in cigarettes, such as figure 1 shown, including the following steps:

[0032] First, select the natural pagoda tree leaves, wash them, and remove impurities;

[0033] Then, separate the leaves and stems, which is the so-called lifting process, to remove most of the coarse fibers in the leaves, of course, the cleaner the better;

[0034] Afterwards, the lifted natural locust tree leaves are crushed and juiced;

[0035] Then, solid-liquid separation is carried out on the crushed and juiced materials, and the liquid plant puree with chlorophyll is reserved for use.

[0036] The above process is the process of preparing plant puree with chlorophyll.

[0037] Adding water to the above-mentioned plant puree with chlorophyll for dilution to prepare chlorophyll with a certain concentration.

[0038] Then add appropriate amount of gene muscle masterbatch, potassium sorbate, far-infrared marble, blood r...

Embodiment 2

[0041] In the production process of the above-mentioned harmful gas filter agent in cigarettes, two steps of vacuum operation are added, that is, after the preparation of the masterbatch is completed, a step of vacuum operation is added to eliminate mold and other impurities in the masterbatch. bacteria.

[0042] In addition, after the finished product is prepared, a vacuum operation step is also carried out to ensure the purity of the finished product.

Embodiment 3

[0044] When changing the amount of supplementary materials such as gene muscle masterbatch, potassium sorbate, far-infrared marble and blood red antioxidant added to the masterbatch, finished products with different proportions can be obtained. As shown in the table below, the proportions of the above ingredients are different, and the corresponding finished products are made.

[0045] ingredients

Content (parts by weight)

Content (parts by weight)

Content (parts by weight)

Content (parts by weight)

15%

20%

30%

40%

Gene muscle masterbatch

28%

25%

30%

35%

Potassium sorbate

25%

20%

20%

15%

Far Infrared Marble

20%

15%

18%

10%

25%

20%

30%

10%

Detoxification

1.0

1.5

2.0

2.5

Hydrated aluminosilicate

1.0

1.5

2.0

2.5

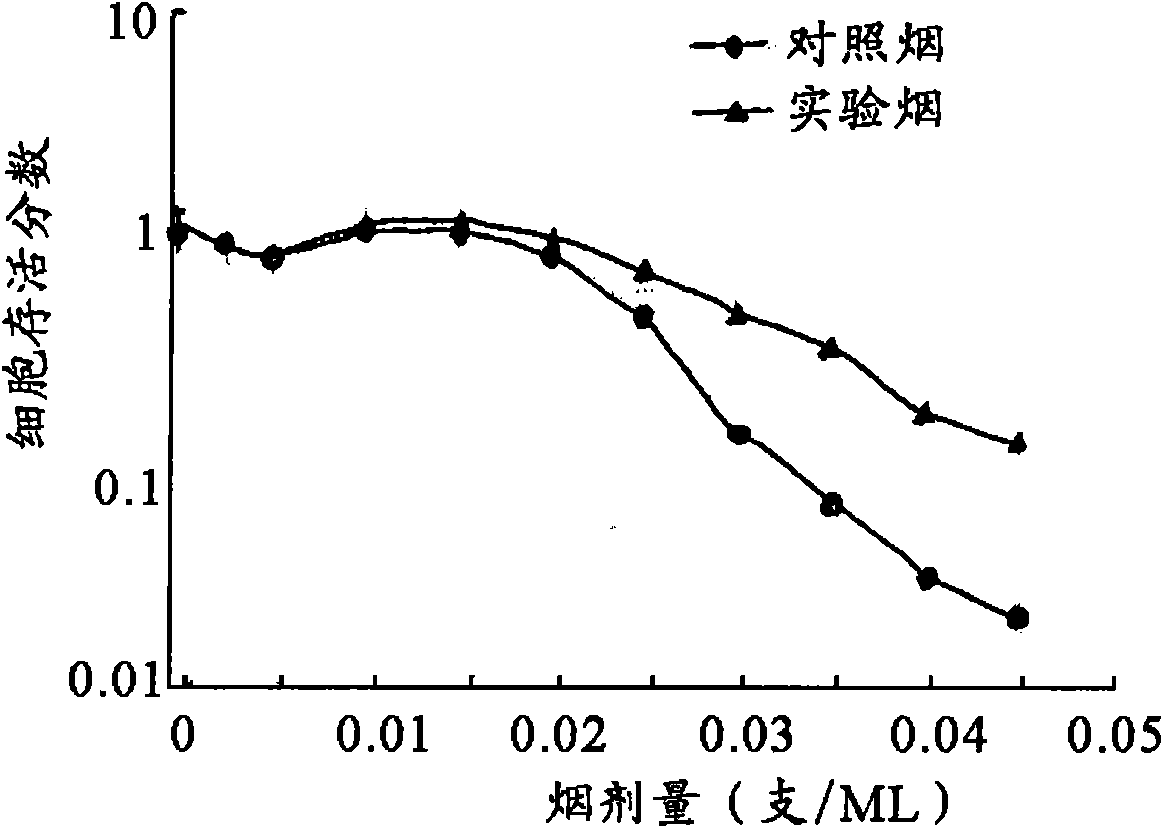

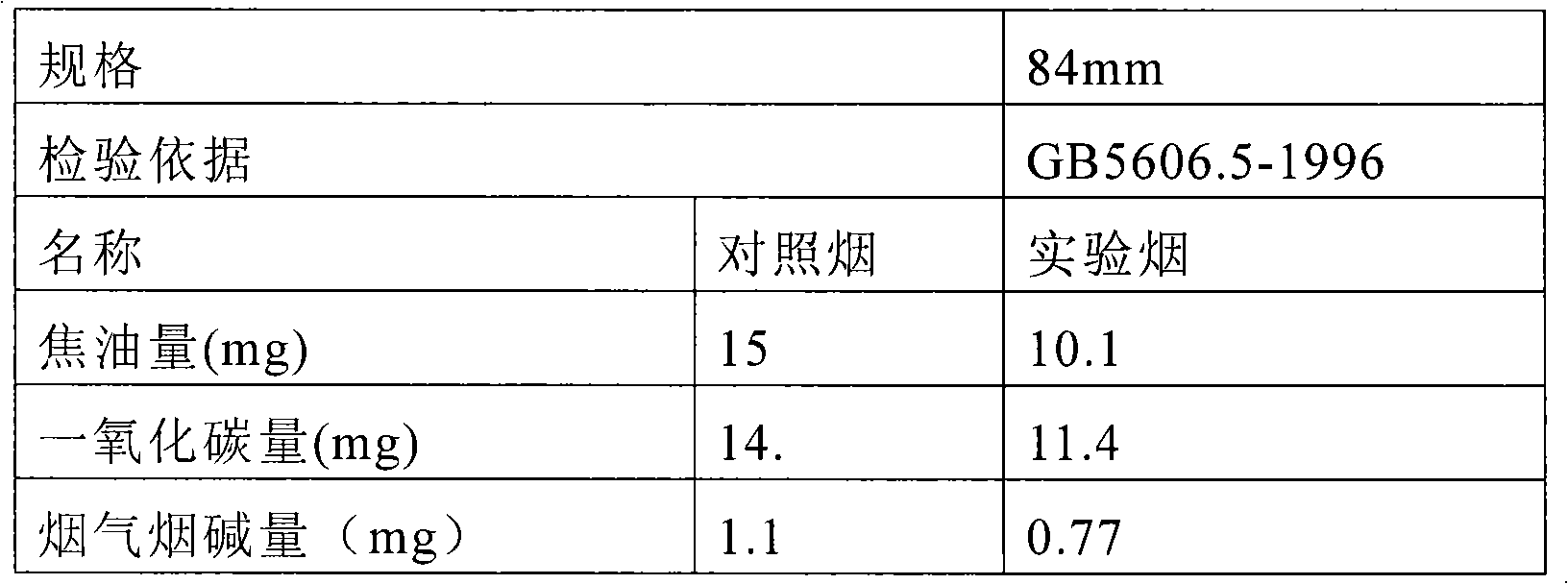

[0046] For the use of the harmful gas filter in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com