High performance soft magnetic ferrite materials doped with Ni-Zn series and preparation method thereof

A soft magnetic material and ferrite technology, applied in the field of high-performance doped nickel-zinc ferrite soft magnetic material and its preparation, can solve the problems of no signal, magnetic core burst, temperature rise, etc., and achieve a simple process. , the effect of light weight and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032]The preparation method comprises the following process steps and contents:

[0033] (1) Weigh raw materials according to the design composition of the Ni-Zn series ferrite soft magnetic material, and add 0-10 wt% of dispersant and binder.

[0034] (2) Mix the claimed powder with high-purity and high-wear-resistant zirconia grinding media and deionized water in a polyurethane ball mill tank, grind and mix evenly on a high-energy ball mill.

[0035] (3) Dry the finely mixed slurry in a drying oven.

[0036] (4) Grind the dried powder, mix and granulate.

[0037] (5) Select a sieve with a suitable aperture and mesh number to sieve the mixed and granulated powder.

[0038] (6) Dry press the ground powder in a mold with specified specifications and shapes.

[0039] (7) Synthesize and sinter the ferrite soft magnetic material according to the preset sintering system.

[0040] In the ball mill, the grinding media are high-purity and high-wear-resistant zirconia balls with a...

Embodiment 1

[0047] Embodiment 1: commercially available analysis pure ZnO, NiO, Fe 2 o 3 、 Bi 2 o 3 , MnCO 3 、Al 2 o 3 For mixing, ZnO, NiO, Fe 2 o 3 、Al 2 o 3 The molar ratio ratio is ZnO:NiO:Fe 2 o 3 : Al 2 o 3 =49.40:25.00:25.00:0.60, with respect to the total weight of other components, 1.0 wt% of Bi was added 2 o 3 and 2.0wt% MnCO 3 , and added 0.3wt% polyvinyl alcohol and 0.05wt% Davon C. According to the powder of 1:4:2: grinding ball: deionized water (mass ratio) into the polyurethane ball mill tank, after ball milling on the ball mill for 24 hours, dry in the air at 130°C in a drying oven for 24 hours , after being ground and sieved, dry-pressed into a ring shape, sintered at 1175°C for 2 hours, kept at 300°C for 2 hours, with a heating rate of 2°C / min, and cooled with the furnace.

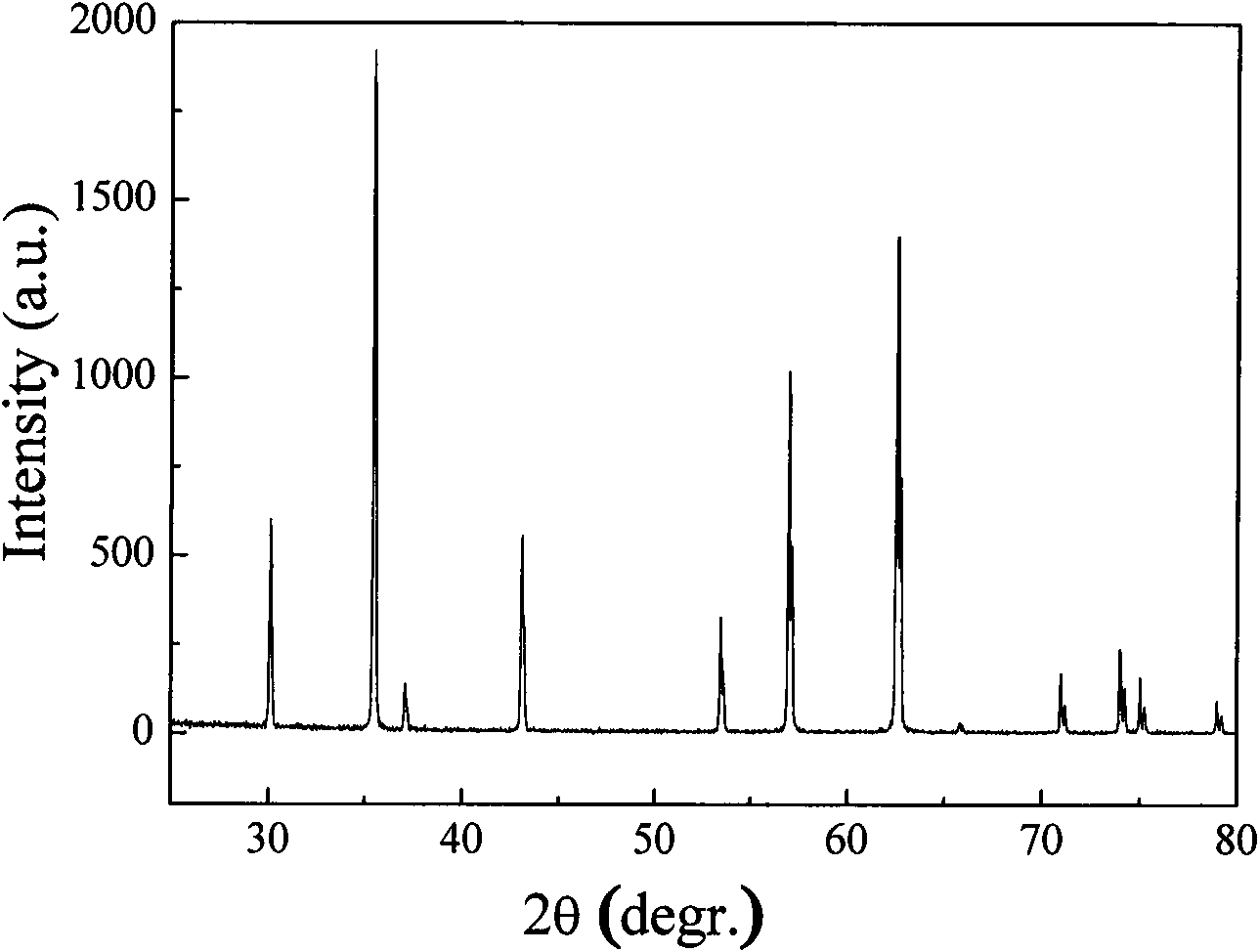

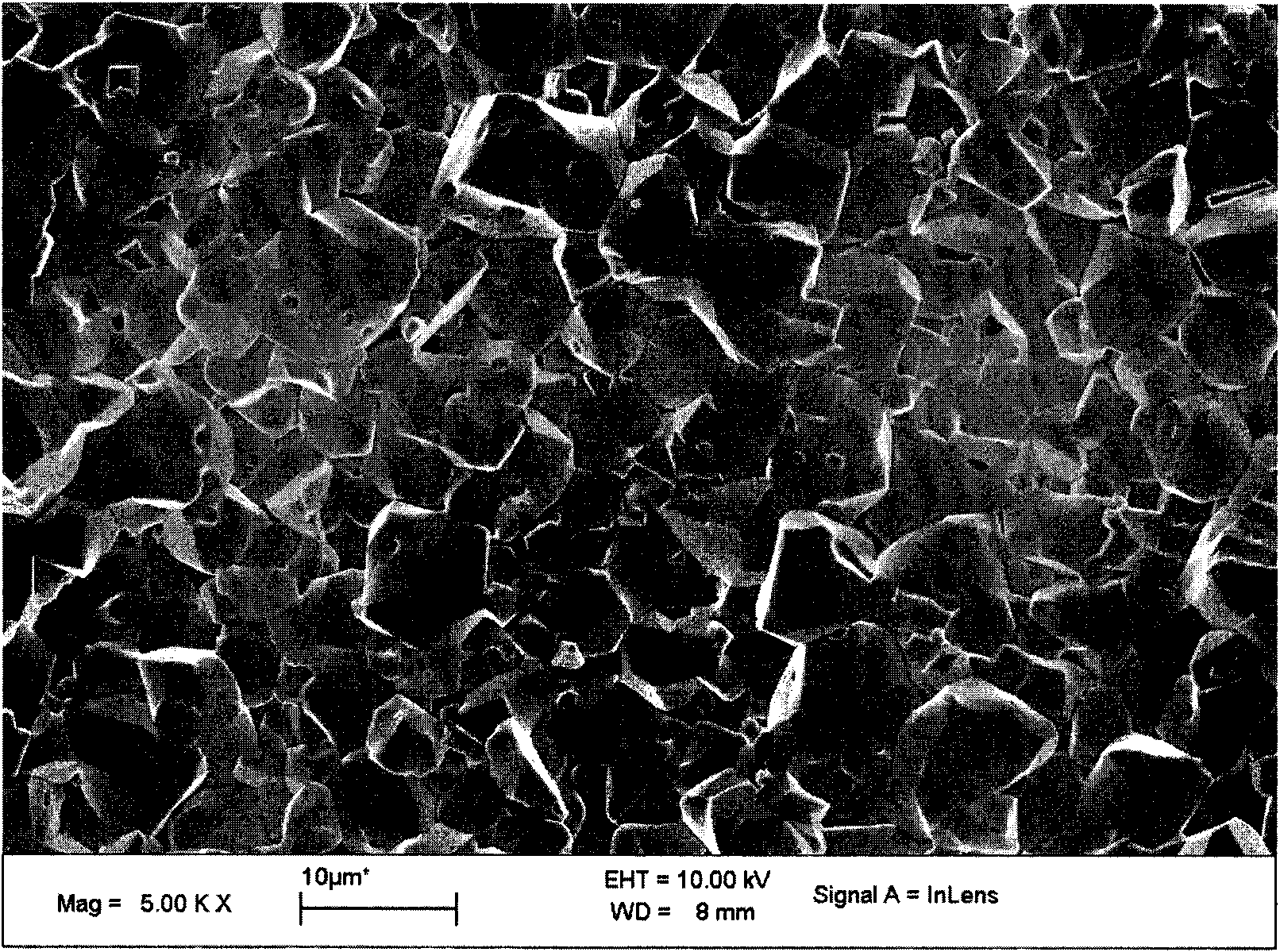

[0048] The resulting material is a phase-pure spinel ferrite (see figure 1 ), the grain size is relatively uniform (see figure 2 ), the initial permeability μ at a frequency of 1M...

Embodiment 2

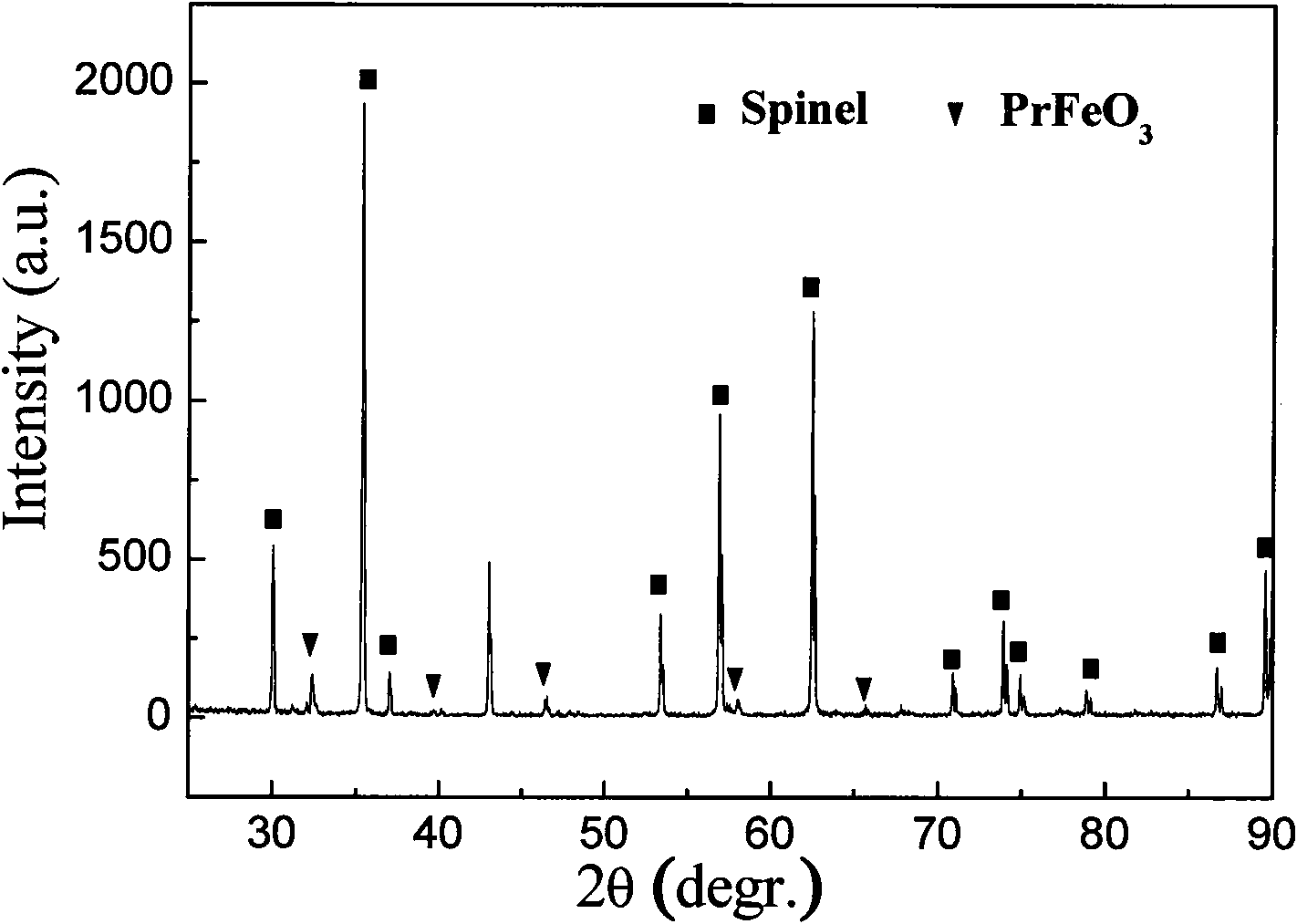

[0049] Embodiment 2: commercially available analysis pure ZnO, NiO, Fe 2 o 3 、 Bi 2 o 3 , MnCO 3 、Pr 6 o 11 For mixing, ZnO, NiO, Fe 2 o 3 、Pr 6 o 11 The molar ratio ratio is ZnO:NiO:Fe 2 o 3 :Pr 6 o 11 =49.33:25.17:25.17:0.34, with respect to the total weight of other components, 1.0 wt% of Bi was added 2 o 3 and 2.0wt% MnCO 3 , and added 0.3wt% polyvinyl alcohol and 0.05wt% Davon C. According to the mass ratio of 1:4:2 powder: zirconium ball: deionized water, put it into the polyurethane ball mill tank, after ball milling on the ball mill for 24 hours, dry in the air at 130°C in a drying oven for 24 hours, after grinding , dry pressed into a ring, sintered at 1150°C for 2 hours, kept at 300°C for 2 hours, the heating rate was 2°C / min, and cooled with the furnace. The resulting material is a typical two-phase structure (comprising a spinel phase and a phase mainly composed of praseodymium ferrite, see figure 1 ), the grain size is relatively uniform (see f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie temperature | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

| Curie temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com