Foamed hollow plastic fender product and production method

A fender and hollow technology, applied in the field of foamed hollow plastic fender products, can solve the problems of being easy to bend, not easy to float, and damaging the living environment of marine organisms, so as to increase the elastic modulus and stiffness, reduce the pressure of white pollution, The effect of excellent chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

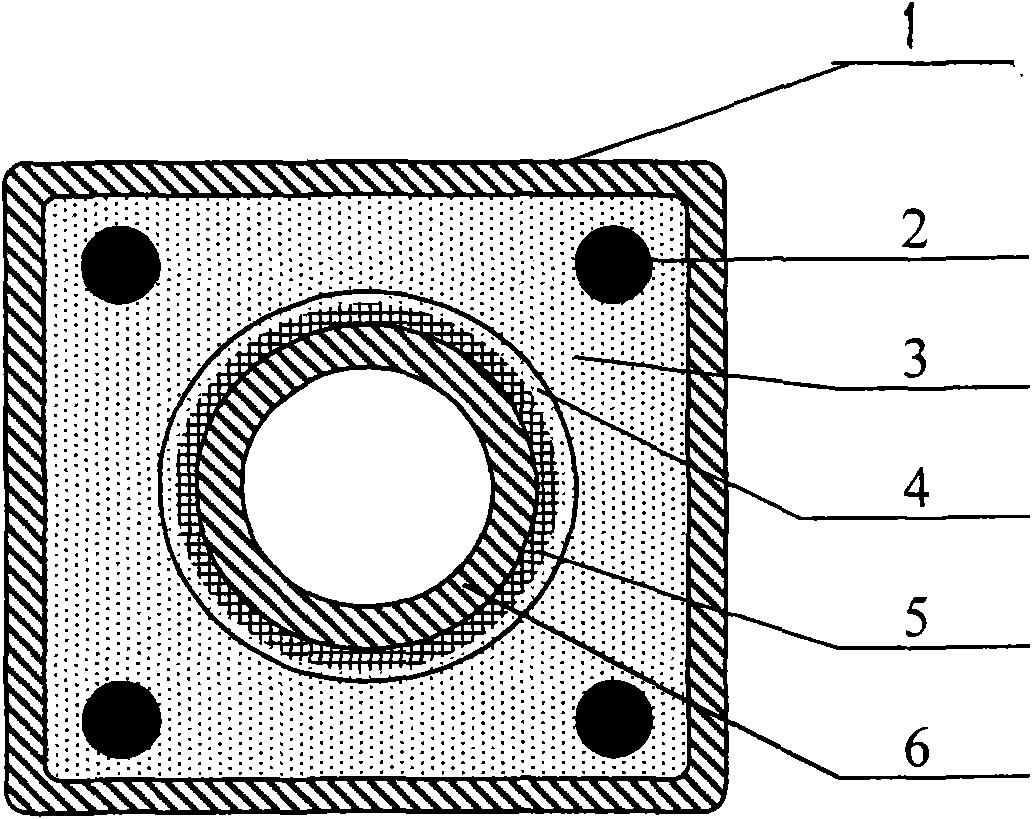

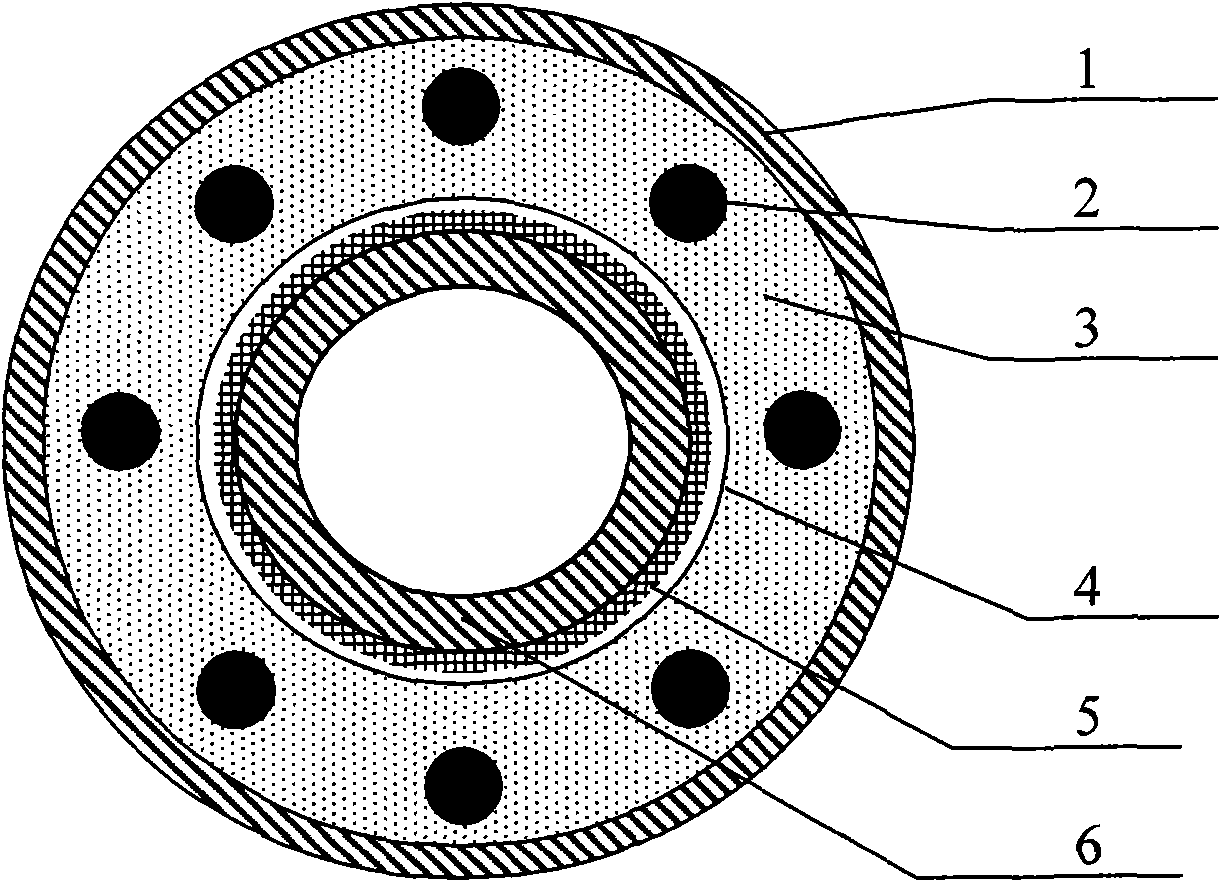

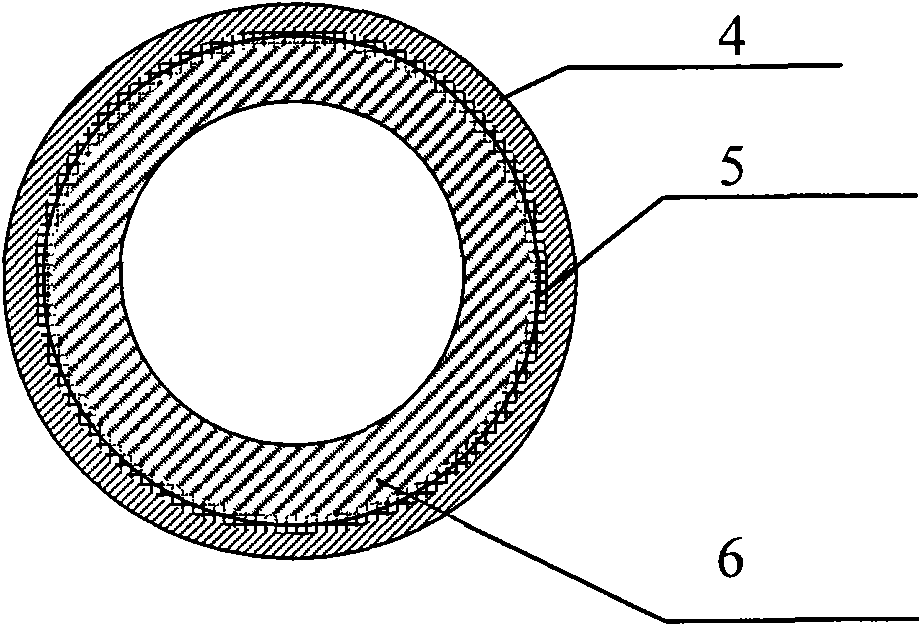

[0019] See figure 1 , 2 , the product structure provided by the present invention is as follows: the shape of the fender product can be square, cylindrical or rectangular, and the outer skin 1 of the main body of the fender is made of recycled high-strength polyethylene material with a thickness of 5-12mm. Inside the outer skin 1 is a filling layer 3, and the filling layer 3 is made of low-density polyethylene and high-density polyethylene mixed foaming material, and its density is 0.75-0.82. A center hole is set in the main body of the fender, and an inner core outer layer 4, a reinforcement layer 5, and an inner core inner layer 6 are sequentially arranged between the filling layer 3 and the center hole, and a high-strength extruded rod 2 is set in the filling layer 3. The number of high-strength extruded rods 2 is determined according to design requirements. The diameter of the central hole is 0.4 to 0.5 times the diameter of the outer shape or the largest section. The o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com