Crylic acid rosin epoxy resin, curing method and application thereof

A technology of acrylic rosin epoxy resin and curing method, which is applied in the direction of epoxy resin glue, epoxy resin coating, plastic/resin/wax insulator, etc., which can solve the problems of short fat chain and brittle cured product, so as to avoid brittleness, Low glass transition temperature and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

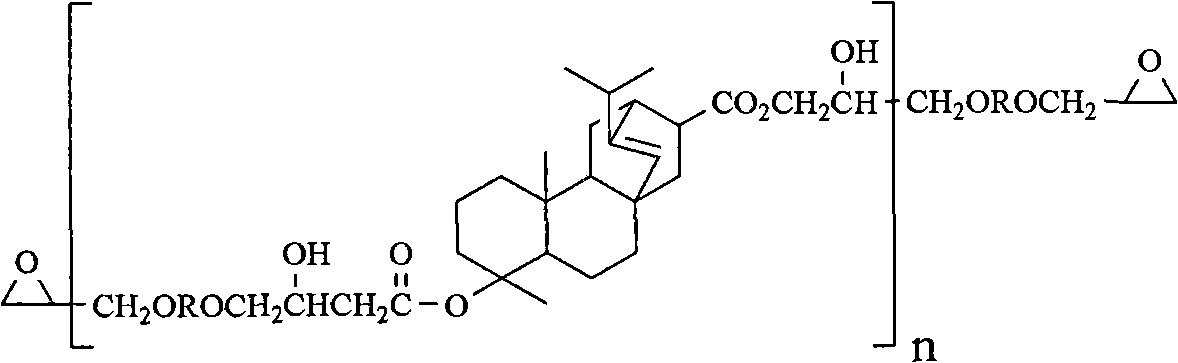

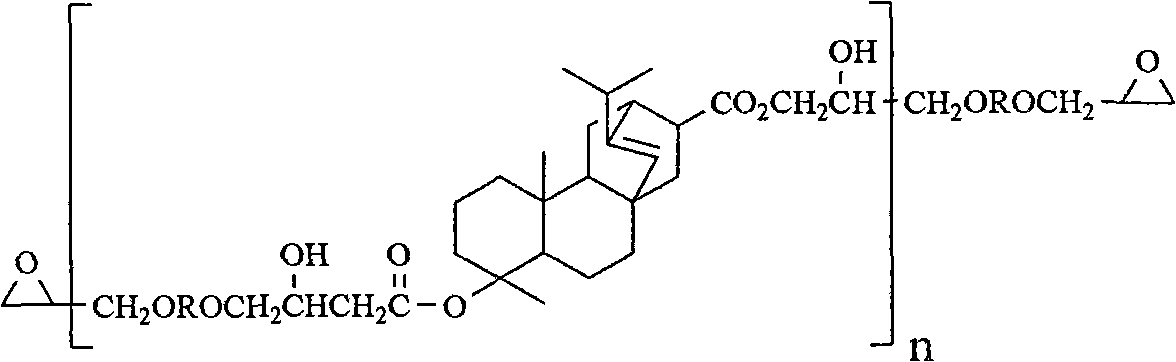

[0028] Regular solidification: the ratio of the amount of substances is 1:2 acrylic rosin and butanediol diglycidyl ether to synthesize acrylic rosin epoxy resin prepolymer (epoxy value 0.19mol / 100g) chemical formula is as follows:

[0029]

[0030] Get the above-mentioned acrylic rosin epoxy resin prepolymer of 10g, 4.17g dodecyl succinic anhydride (the ratio of the amount of the epoxy group in the acrylic rosin epoxy resin prepolymer and the anhydride substance in the dodecyl succinic anhydride is 1:0.8) and 0.08g of triethylamine were mixed uniformly, poured into a mold, pre-cured at 120°C for 2 hours, and post-cured at 190°C for 6h to obtain a cured product of acrylic rosin epoxy resin. The curing agent dodecyl succinic anhydride was purchased from Jiangsu Minsheng Trading Co., Ltd.

Embodiment 2

[0032] Random curing: first dissolve 4.5g of acrylic rosin with acetone and mix it with 4.17g of dodecyl succinic anhydride, put the mixture in a blast oven at 80°C to remove acetone, then add 5.5g of butanediol diglycidyl ether (The ratio of the epoxy group in the butanediol diglycidyl ether to the carboxyl group in the acrylic rosin is 2:1) and 0.09g triethanolamine are fully mixed, poured into the mold, pre-cured at 120°C for 2 hours, and after 190°C After curing for 8 hours, an acrylic rosin epoxy resin cured product was obtained. The curing agent dodecyl succinic anhydride was purchased from Jiangsu Minsheng Trading Co., Ltd.

Embodiment 3

[0034] Regular curing: first synthesize acrylic rosin epoxy resin prepolymer (epoxy value 0.19mol / 100g) by acrylic rosin and butanediol diglycidyl ether at a molar ratio of 1:2. Get the above-mentioned rosin-based epoxy resin prepolymer of 10g, the dodecyl succinic anhydride of 5.09g (the epoxy group in the acrylic acid rosin epoxy resin prepolymer and the ratio of the anhydride substance in the dodecyl succinic anhydride (1:1) and 0.06g of tetraethylammonium chloride were mixed evenly, poured into a mold, pre-cured at 100°C for 3 hours, and post-cured at 170°C for 8h to obtain a cured product of acrylic rosin epoxy resin. The curing agent dodecyl succinic anhydride was purchased from Jiangsu Minsheng Trading Co., Ltd.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy value | aaaaa | aaaaa |

| Epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com