Method for preparing carbon/carbon composite profiles

A carbon composite material and composite material technology, which is applied in the field of preparation of carbon/carbon composite material profiles, can solve problems not involved in the preparation method of carbon/carbon composite material profiles, achieve simple shaping methods, reduce production costs, and shorten production cycles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

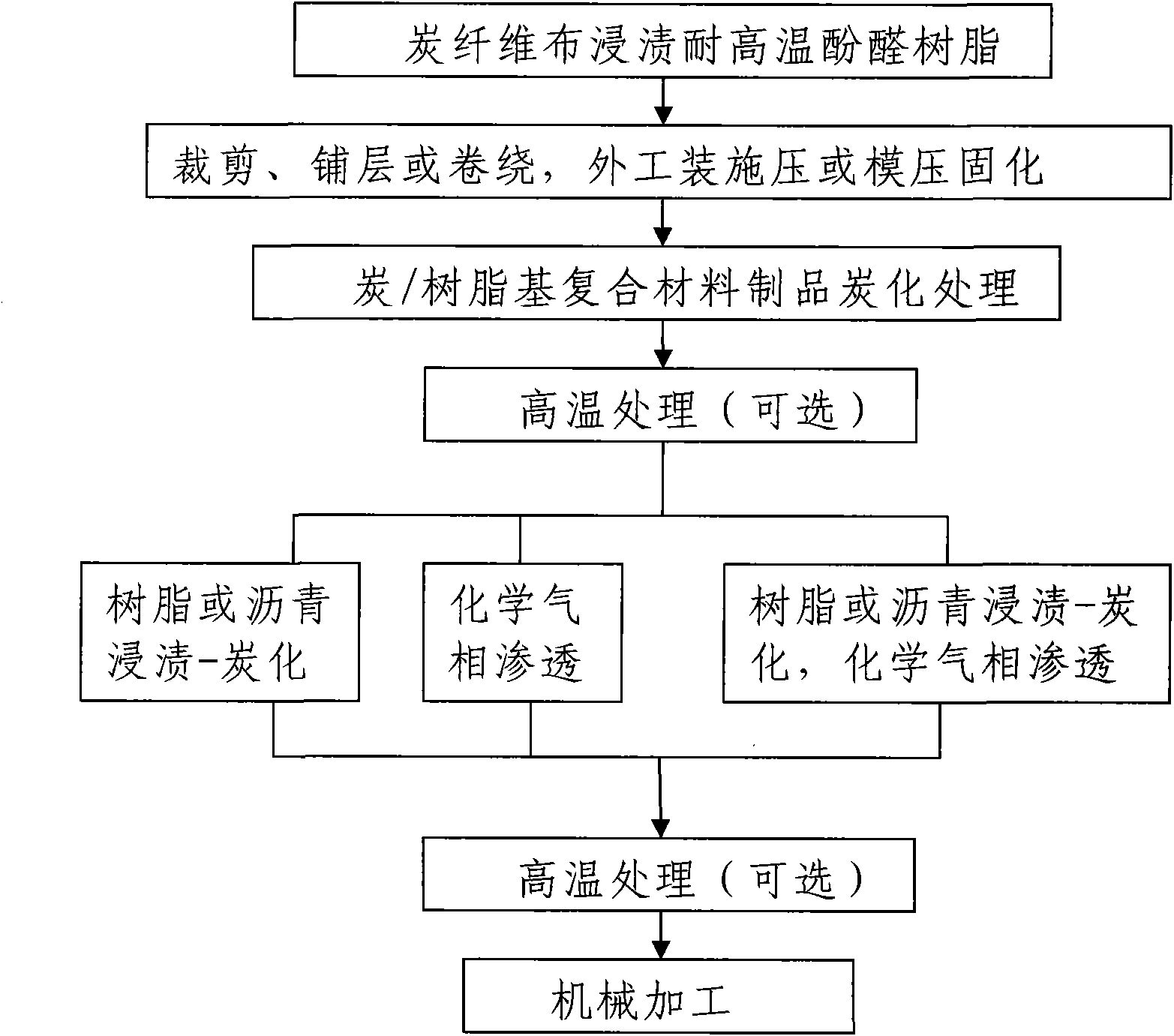

Method used

Image

Examples

Embodiment 1

[0024] (1) 1K viscose silk-based plain carbon cloth is impregnated with resin by dipping machine, and the glue content is about 20wt%; the carbon cloth is cut and laid on the graphite mandrel; external pressure is applied to cure and shape the final curing temperature The temperature is about 150°C, and the density is 1.10g / cm 3 Carbon / resin composite profile parts;

[0025] (2) Put the carbon / resin composite profile parts in the carbonization furnace for N 2 Carbonization treatment under protection, the temperature is 600°C, the resin matrix is converted into resin carbon, and the carbon / resin composite material is transformed into a carbon / carbon composite material product, with a density of 0.90g / cm 3 ;

[0026] (3) The charcoal / charcoal products that have been carbonized are subjected to high-temperature opening treatment at 1300-2600°C;

[0027] (4) Carry out one cycle of asphalt pressure impregnation-carbonization densification and one CVI densification on the carbo...

Embodiment 2

[0031] (1) 6K asphalt-based twill carbon cloth is impregnated with resin through a dipping machine, and the glue content is about 40wt%; the carbon cloth is wound on a steel mandrel; it is molded and cured by a hot press, and the final curing temperature is about 180°C , made with a density of 1.25g / cm 3 Carbon / resin composite profile parts;

[0032] (2) Put the carbon / resin composite profile parts in the carbonization furnace for N 2 Carbonization treatment under protection, the temperature is 800°C, the resin matrix is converted into resin carbon, and the carbon / resin composite material is transformed into a carbon / carbon composite product with a density of 1.15g / cm 3 ;

[0033] (3) The carbonized carbon / carbon products are subjected to 2 cycles of resin pressure impregnation-carbonization supplementary densification and 1 cycle of CVI densification, and the density of the product after supplementary densification is 1.50g / cm 3 ;

[0034] (4) Put the supplemented and d...

Embodiment 3

[0037] (1) The 24K polyacrylonitrile-based satin carbon cloth is impregnated with resin by a dipping machine, and the glue content is about 60wt%; the carbon cloth is cut and laid on the steel mandrel; the external pressure is applied to solidify the shape through the external tooling, and the solidification is completed. The temperature is about 220°C, and the density is 1.20g / cm 3 Carbon / resin composite profile parts;

[0038] (2) Put the carbon / resin composite profile parts in the carbonization furnace for N 2 Carbonization treatment under protection, the temperature is 1100°C, the resin matrix is converted into resin carbon, and the carbon / resin composite material is transformed into a carbon / carbon composite product with a density of 1.05g / cm 3 ;

[0039] (3) Carry out 3 cycles of CVI densification on the carbonized carbon / carbon product, and the density of the product after the densification is 1.45g / cm 3 ;

[0040] (4) After the carbon / carbon products after suppleme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com