Arsenic-containing solid material and method for production thereof

A solid-state, iron-arsenic technology, applied in arsenic compounds, chemical instruments and methods, iron compounds, etc., can solve the problems of increased dissolution and insufficient arsenic removal, shortening the reaction time, improving the dissolution prevention effect, and stabilizing And the effect of excellent arsenic elution prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

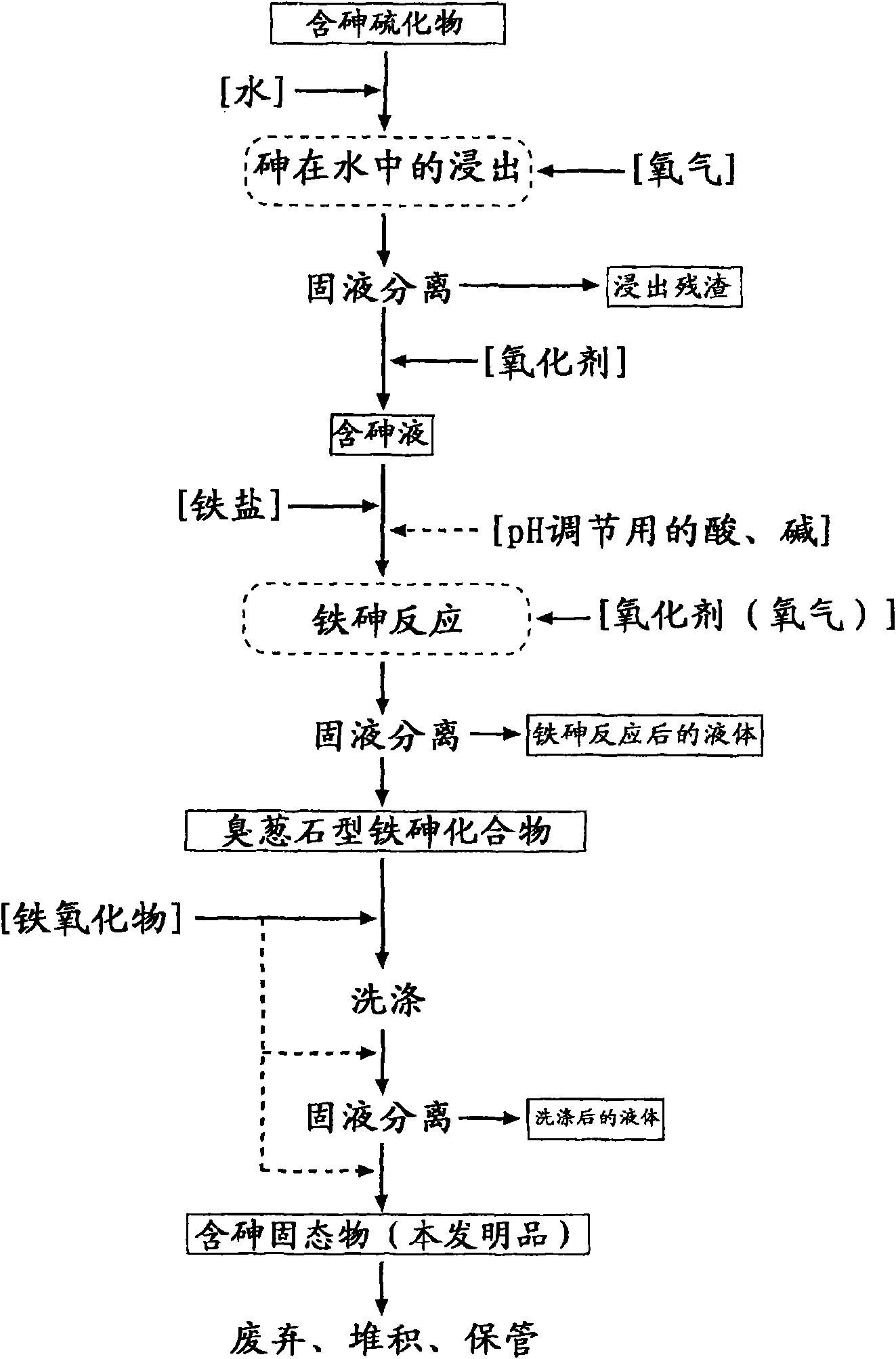

[0020] "Preparation of arsenic solution"

[0021] As a raw material solution for synthesizing scorodite-type iron-arsenic compounds, an arsenic-containing solution (a solution in which arsenic is dissolved) was prepared. The arsenic-containing liquid can be produced by leaching arsenic from arsenic-containing substances generated in a smelting process or the like. As this method, for example, methods disclosed by the present applicant in Japanese Patent Application No. 2006-339154, Japanese Patent Application No. 2006-339156, etc. can be preferably used. For example, when using As 2 S 3 Or when the sulfide represented by the composition formula of CuS is the main arsenic-containing substance, oxygen is added to the slurry in which the above-mentioned sulfide is suspended in water, and the leaching reaction of arsenic is carried out while stirring. After the reaction, the slurry is solid-liquid The resulting liquid is separated and recovered to obtain an arsenic-containing l...

Embodiment 1

[0048] The same operation as in Comparative Example 1 was carried out to obtain a dry solid product composed of scorodite-type iron-arsenic compound.

[0049] On the other hand, iron oxide of a special grade reagent (manufactured by Kanto Chemical Co., Ltd.) was prepared as the iron oxide.

[0050] The X-ray diffraction pattern was measured for this iron oxide (measurement conditions are the same as above). As a result, the iron oxide was identified as hematite (α-Fe 2 o 3 ).

[0051] In addition, the particle size distribution was measured using a laser diffraction particle size distribution analyzer (manufactured by Horiba, Ltd., LA-500). As a result, the average particle size D of the iron oxide was 50 is 20.22 μm.

[0052] Then, the BET specific surface area was measured by the BET one-point method (using Yuasa Ionix Co., Ltd., Monosorb), and the BET specific surface area of the iron oxide was 4.64 m 2 / g.

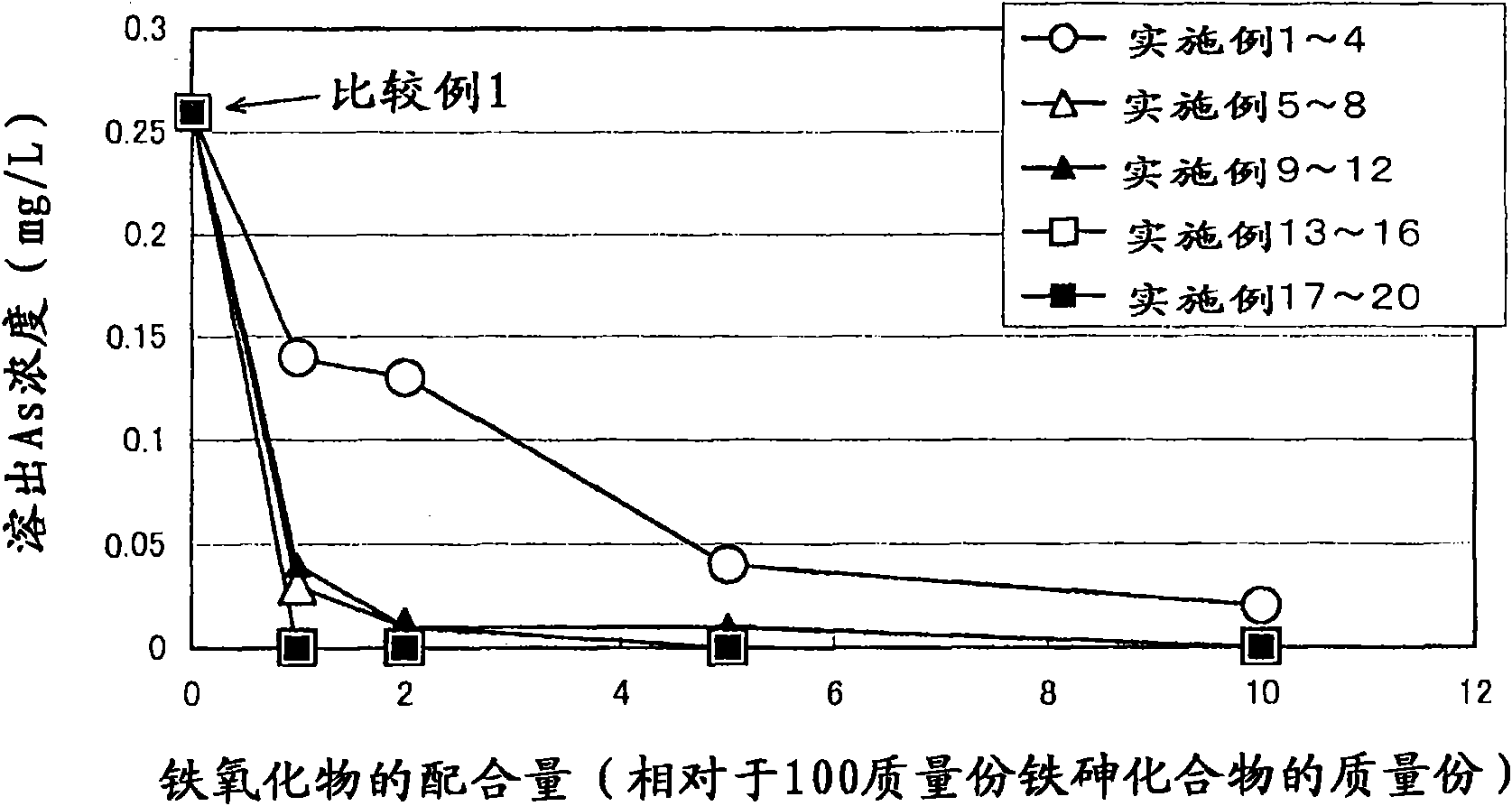

[0053] In the dissolution test carried out in Comparative...

Embodiment 2

[0056] The dissolution test was performed under the same conditions as in Example 1, except that a slurry containing 5 parts by mass of iron oxide per 100 parts by mass of the iron-arsenic compound was used as the slurry for the dissolution test. As a result, the pH after shaking was 3.79, and the arsenic concentration was 0.04 mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com