Nano modification high-density polyethylene composite material and method for preparing same

A technology of high-density polyethylene and composite materials, which is applied in the field of high-performance high-density polyethylene nano-composite materials and its preparation, can solve the problems of high price, complicated surface treatment process, and limited improvement of polyethylene impact strength, and achieve easy Operation, improved tensile strength and impact strength, simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The best way to implement the present invention will be introduced below with respect to various factors affecting the performance of the nano-modified high-density polyethylene composite material.

[0009] The nano-powder of the present invention is barium sulfate powder (such as Pla-800 nano-barium sulfate of Shanghai Anyi Nano Material Co., Ltd.) or ore powder containing barium sulfate. The main components of ore powder are multiple compounds such as barium, strontium and silicon. The particle size of the ore powder containing barium sulfate is 10-50 nm.

[0010] The modified nanometer powder in the present invention is barium sulfate powder coated and modified by sodium stearate, or ore powder containing barium sulfate coated and modified by sodium stearate.

[0011] The preparation process of nano-modified high-density polyethylene composite material is as follows:

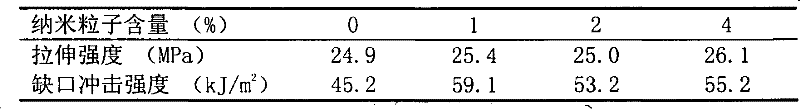

[0012] Mix the modified nano-powder with high-density polyethylene, wherein the mass percentage o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com