Components and parts of mechanical machine tool and manufacturing method thereof

A manufacturing method and component technology, applied in the field of mechanical machine tool components and their manufacturing, can solve the problems of poor machining accuracy stability, pollution, energy consumption, etc., and achieve the effects of not being easy to resonate, reducing manufacturing costs, reducing consumption and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

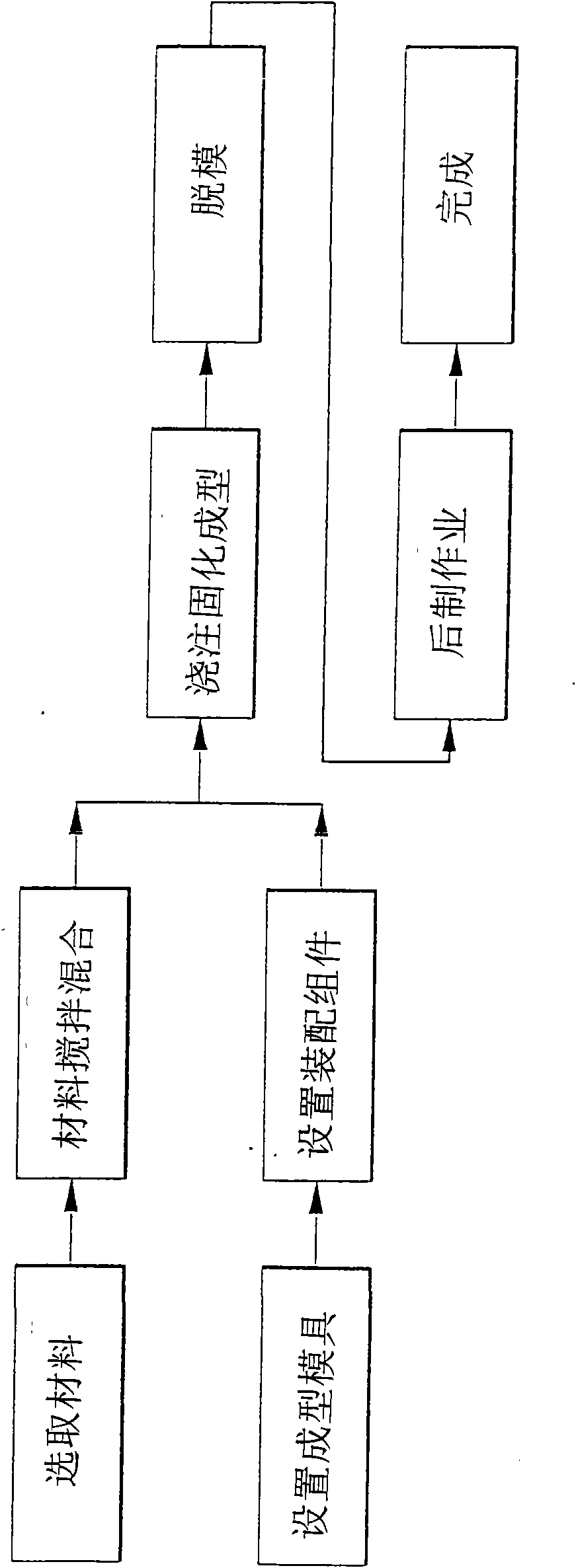

[0052] The manufacturing process of the preferred embodiment of the mechanical machine tool parts manufacturing method provided by the present invention is as follows figure 1 Shown, process of the present invention comprises:

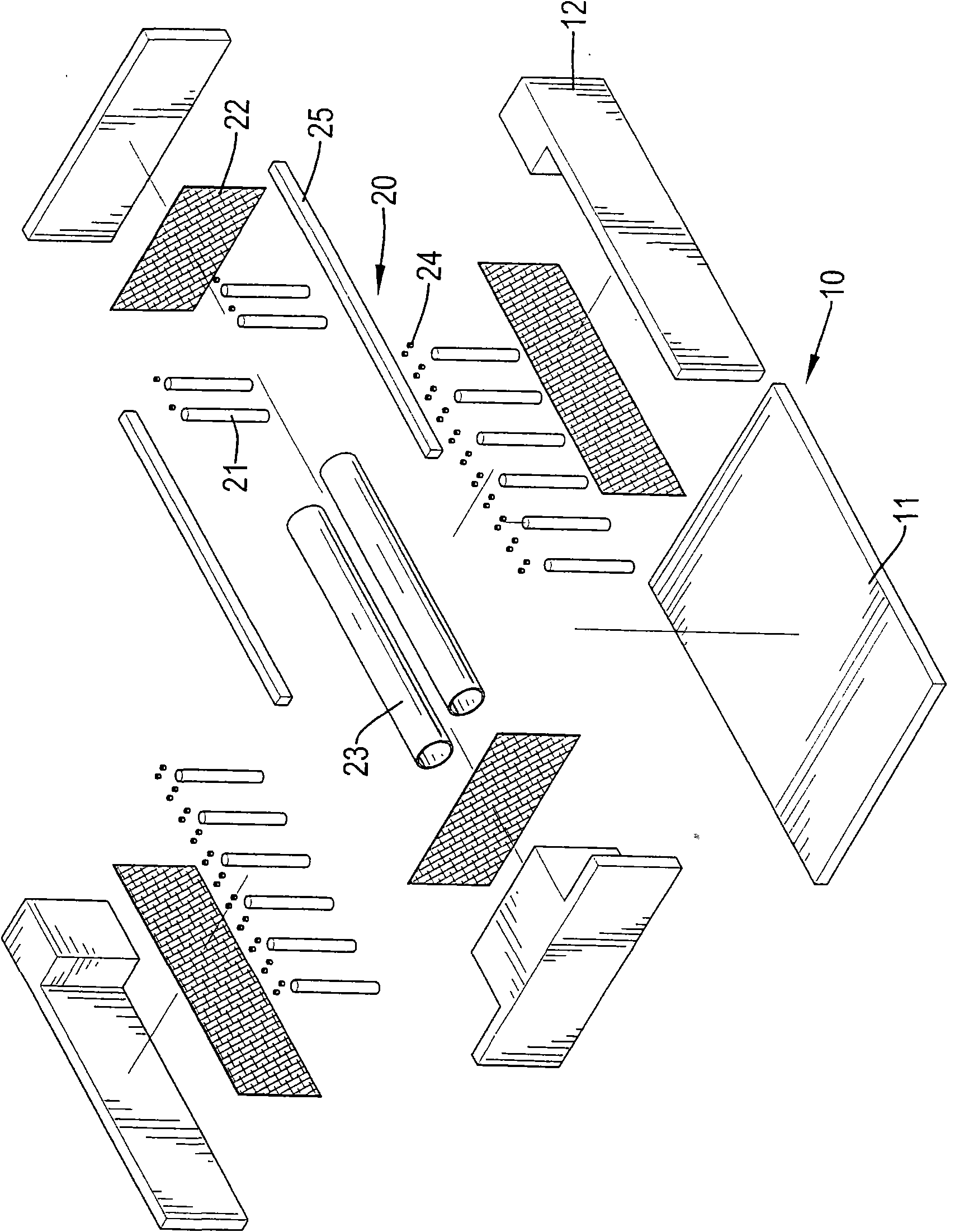

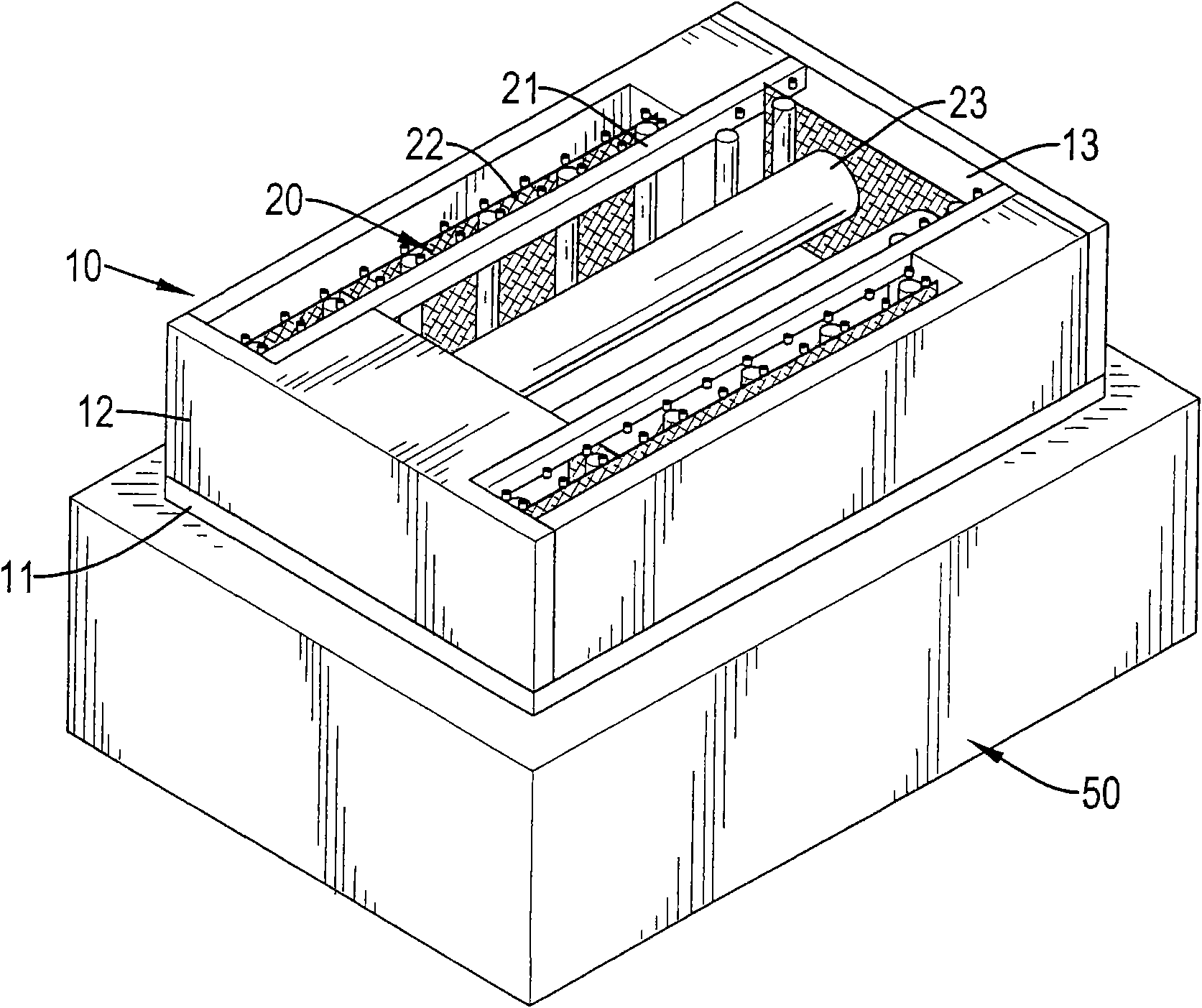

[0053] 1. Select materials: choose powdery and granular high-rigidity stones and glass materials for future use. The high-rigidity stone materials and glass materials can be purchased directly as new products for future use, or they can be processed by reclaimed waste materials for future use; preferred embodiments of the present invention It is to collect waste granite and other high-rigidity stone materials, or to recycle the waste materials produced during the processing of high-rigidity stone materials such as granite, and to crush the high-rigidity stone waste materials into powder and granules for later use; and to collect waste glass waste materials, or to recycle glass The waste generated during processing, and the glass waste is crushed into p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com